Preparation method for p-hydroxy benzaldehyde

A technology of p-hydroxybenzaldehyde and methanol solution, which is applied in the chemical industry, can solve the problems of complex preparation process and low production efficiency, and achieve the effects of improving purity, improving utilization rate and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

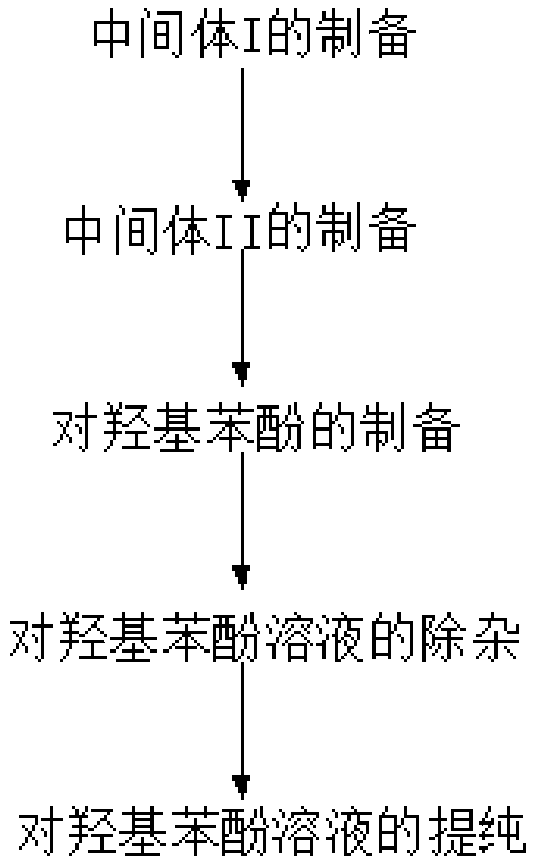

[0022] Such as figure 1 A kind of preparation method of shown p-Hydroxybenzaldehyde, comprises the steps:

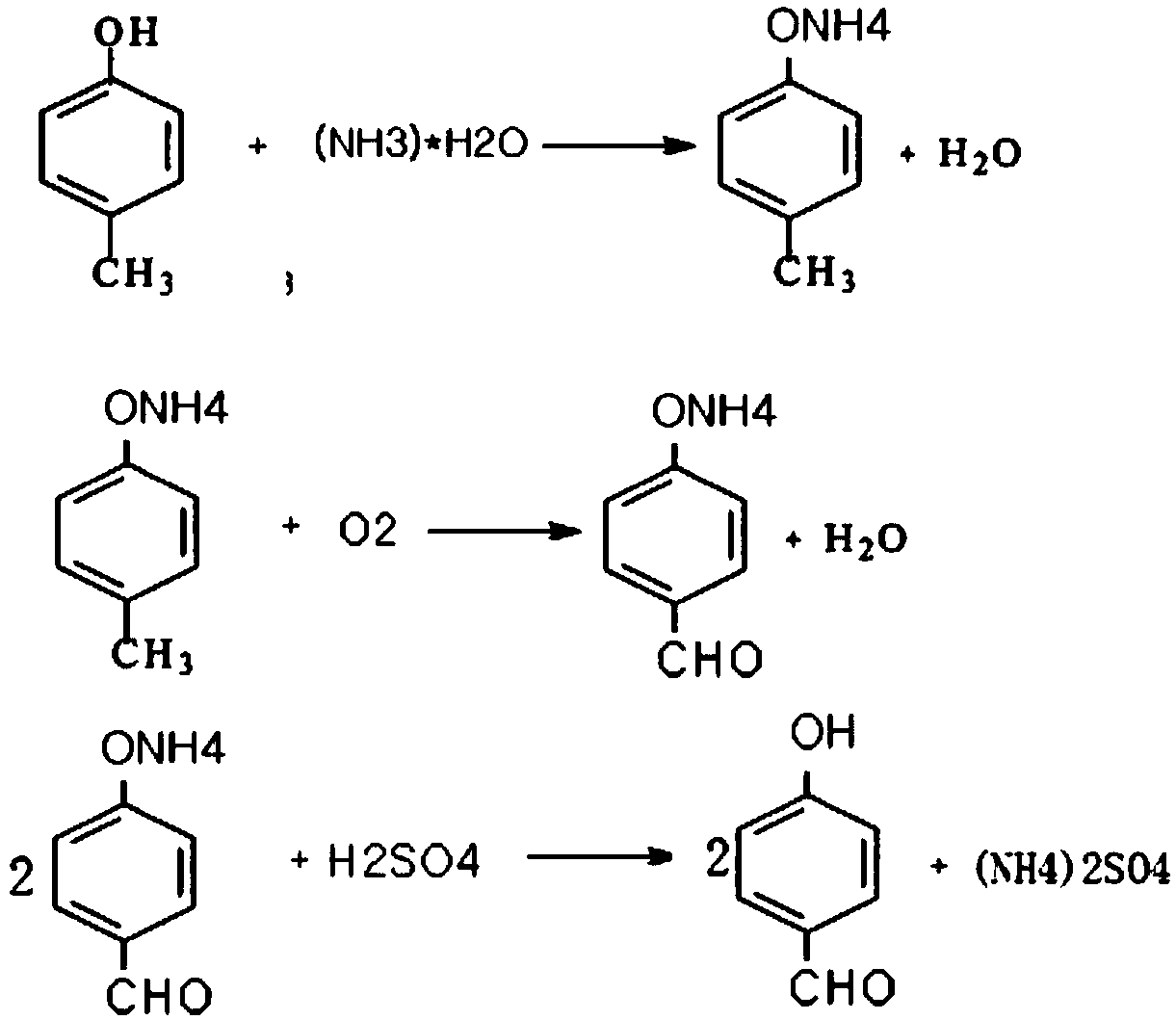

[0023] 1) Preparation of Intermediate I: P-cresol solution is placed in a quartz reactor, and then an excess of 50-64% (NH3) H2O solution and an appropriate amount of catalysis are added to the quartz reactor. Keep the temperature in the range of 8-16° C., and stir and mix with a stirring device for 70-90 minutes under strong light irradiation to obtain a mixed solution of intermediate I, methanol solution and (NH3)·H2O.

[0024] 2) Preparation of Intermediate II: In the mixed solution obtained in Step 1) to obtain Intermediate I, methanol solution and (NH 3 )·H 2 O, oxygen with a concentration of 90-98% is continuously fed into it, and a stirring device is used while feeding oxygen The mixed solution was stirred for 2h to obtain a mixed solution of intermediate II, methanol solution and (NH3)·H2O.

[0025] 3) Preparation of p-Hydroxybenzaldehyde: In a low temperature ...

Embodiment 2

[0033] Such as figure 1 A preparation method for p-Hydroxybenzaldehyde, comprising the steps of:

[0034] (1) Preparation of Intermediate I: P-cresol solution is placed in a quartz reactor, then an excess of 50-64% (NH3) H2O solution and an appropriate amount of The catalyzed methanol solution was kept at a temperature of 8-16°C, and under strong light irradiation, it was stirred and mixed with a stirring device for 70-90 minutes to obtain a mixed solution of intermediate I, methanol solution and (NH3)·H2O.

[0035] 2) Preparation of Intermediate II: In the mixed solution obtained in Step 1) to obtain Intermediate I, methanol solution and (NH 3 )·H 2 O, oxygen with a concentration of 90-98% is continuously fed into it, and a stirring device is used while feeding oxygen The mixed solution was stirred for 3h to obtain a mixed solution of intermediate II, methanol solution and (NH3)·H2O.

[0036] 3) Preparation of p-Hydroxybenzaldehyde: In a low temperature environment of 4-8°C...

Embodiment 3

[0044] Such as figure 1 Shown, a kind of preparation method of p-Hydroxybenzaldehyde comprises the steps:

[0045] 1) Preparation of Intermediate I: P-cresol solution is placed in a quartz reactor, and then an excess of 50-64% (NH3) H2O solution and an appropriate amount of catalysis are added to the quartz reactor. Keep the temperature in the range of 8-16° C., and stir and mix with a stirring device for 70-90 minutes under strong light irradiation to obtain a mixed solution of intermediate I, methanol solution and (NH3)·H2O.

[0046] 2) Preparation of Intermediate II: In the mixed solution obtained in Step 1) to obtain Intermediate I, methanol solution and (NH 3 )·H 2 O, oxygen with a concentration of 90-98% is continuously fed into it, and a stirring device is used while feeding oxygen The mixed solution was stirred for 2.5h to obtain a mixed solution of intermediate II, methanol solution and (NH3)·H2O.

[0047] 3) Preparation of p-Hydroxybenzaldehyde: In a low temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com