Waterproof antifouling antimicrobial and antibacterial coating material and preparation method thereof

A bactericidal coating and antifouling technology, applied in antifouling/underwater coatings, coatings, polyester coatings, etc., can solve the problems of co-solvent environmental pollution, poor weather resistance, easy to fall off, etc., achieve good effect, easy to promote , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

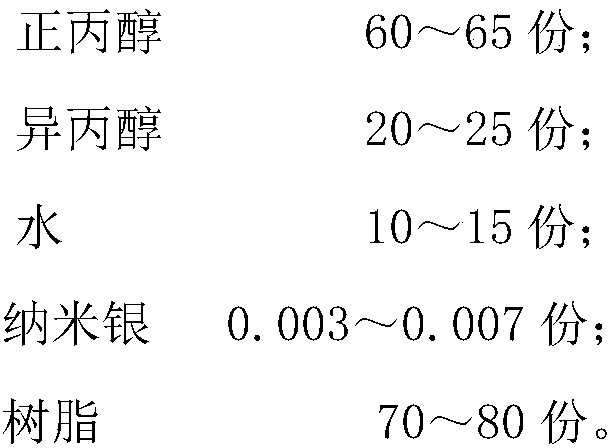

[0028] A waterproof, antifouling, antibacterial and antibacterial coating material, comprising the following components by weight:

[0029]

[0030]

[0031] Further, the water is deionized water.

[0032] Further, the particle size of the nano-silver is between 25nm and 50nm.

[0033] Further, the nano-silver is modified nano-silver.

[0034] Further, the resin is one of epoxy resin, urea-formaldehyde resin, amino resin or alkyd resin.

[0035] A method for preparing a waterproof, antifouling, antibacterial and bactericidal coating material, comprising the following steps:

[0036] S1, each component is weighed according to the weight part of each component;

[0037] S2. Add the resin, nano-silver and water in the above parts by weight to the ball mill, first stir at a speed of 800rpm for 40min, then increase the speed to 2500rpm and continue stirring for 20min, and fully grind the resulting mixed solution to obtain a ground mixed solution;

[0038] S3. Add proporti...

Embodiment 2

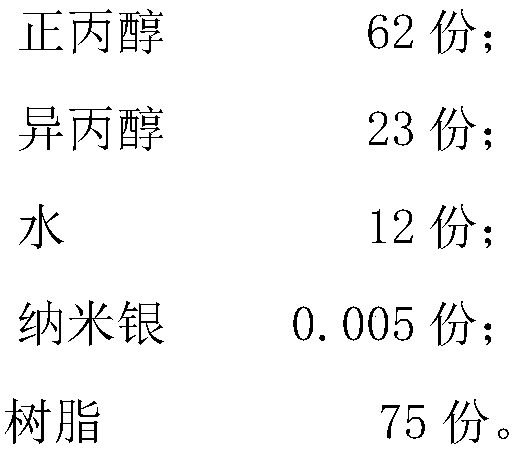

[0045] A waterproof, antifouling, antibacterial and antibacterial coating material, comprising the following components by weight:

[0046]

[0047] Further, the water is deionized water.

[0048] Further, the particle size of the nano-silver is between 25nm and 50nm.

[0049] Further, the nano-silver is modified nano-silver.

[0050] Further, the resin is one of epoxy resin, urea-formaldehyde resin, amino resin or alkyd resin.

[0051] A method for preparing a waterproof, antifouling, antibacterial and bactericidal coating material, comprising the following steps:

[0052] S1, each component is weighed according to the weight part of each component;

[0053] S2. Add the resin, nano-silver and water in the above parts by weight to the ball mill, first stir at a speed of 1000rpm for 35min, then increase the speed to 2200rpm and continue stirring for 25min, and fully grind the resulting mixed solution to obtain a ground mixed solution;

[0054] S3. Then add proportional a...

Embodiment 3

[0061] A waterproof, antifouling, antibacterial and antibacterial coating material, comprising the following components by weight:

[0062]

[0063] Further, the water is deionized water.

[0064] Further, the particle size of the nano-silver is between 25nm and 50nm.

[0065] Further, the nano-silver is modified nano-silver.

[0066] Further, the resin is one of epoxy resin, urea-formaldehyde resin, amino resin or alkyd resin.

[0067] A method for preparing a waterproof, antifouling, antibacterial and bactericidal coating material, comprising the following steps:

[0068] S1, each component is weighed according to the weight part of each component;

[0069]S2. Add the resin, nano-silver and water in the above weight parts to the ball mill, first stir at a speed of 1200rpm for 30min, then increase the speed to 2000rpm and continue stirring for 30min, and fully grind the obtained mixed solution to obtain a ground mixed solution;

[0070] S3. Add proportional amounts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com