Formula and preparation method used for medium high temperature heat storage iron ore thermophysical property reinforcement

An iron ore, medium-high temperature technology, applied in the formulation and preparation of iron ore thermophysical property strengthening, can solve the problems of low thermal conductivity, low specific heat capacity, etc., and achieve excellent thermal performance, good performance stability, and improved thermal performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

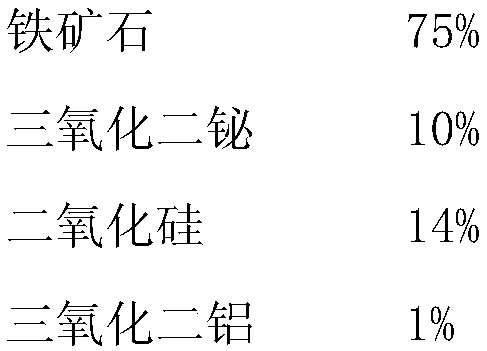

[0027] This example provides a formula of modified iron ore for medium and high temperature heat storage, which can produce modified iron ore products with low sintering temperature and good density. In terms of mass percentage, the formula includes the following components :

[0028]

[0029] The above-mentioned preparation method of a modified iron ore for medium and high temperature heat storage comprises the following steps:

[0030] (1) Sieving the crushed and ground iron ore to obtain iron ore powder with a particle size of <300 μm;

[0031] (2) the iron ore after the step (1) sieved and diboron trioxide, silicon dioxide, aluminum sequester are uniformly mixed according to the formula quantity;

[0032] (3) Keep the mixed powder obtained in step (2) under the pressure of 400MPa for 30s, and then sinter. ℃, and keep it warm for 30 minutes, and finally raise the temperature to 800 ℃ at 10 ℃ / min, keep it warm for 2 hours, and then cool it with the furnace. The modifie...

Embodiment 2

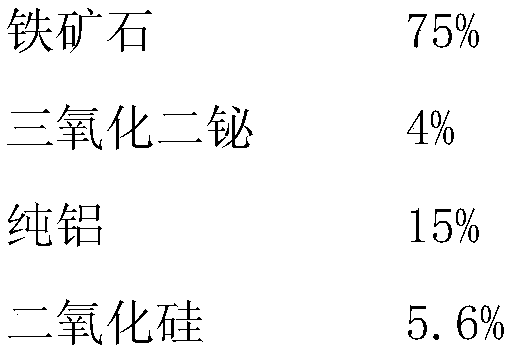

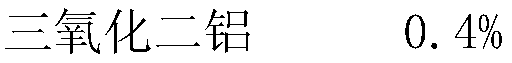

[0034] This example provides a formula of modified iron ore for medium and high temperature heat storage, which can produce modified iron ore products with excellent thermal properties. In terms of mass percentage, the formula includes the following components:

[0035]

[0036]

[0037] The above-mentioned preparation method of a modified iron ore brick for medium and high temperature heat storage comprises the following steps:

[0038] (1) Sieving the crushed and ground iron ore to obtain iron ore powder with a particle size of <300 μm;

[0039] (2) the iron ore after the step (1) sieved and bismuth trioxide, pure aluminum, silicon dioxide, aluminum sesquioxide are uniformly mixed according to the formula quantity;

Embodiment -2

[0040] (3) Keep the mixed powder obtained in step (2) under the pressure of 400MPa for 30s, and then sinter. ℃, and keep it warm for 30 minutes, and finally raise the temperature to 850 ℃ at 10 ℃ / min, keep it warm for 2 hours, and then cool it with the furnace. The modified iron ore brick "Example-2" for medium and high temperature heat storage was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com