A high-temperature alloy metallurgical blade and its manufacturing method

A high-temperature alloy and manufacturing method technology, applied in the field of metallurgical blades and its manufacturing, can solve problems such as fatigue cracks and fractures, blunt edges, poor impact toughness, and poor use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The mass percent of the chemical composition of the superalloy metallurgical blade of the present invention is preferably: Ni: 54.5%, Cr: 20.0%, Mo: 3.1%, Co: 0.5%, W: 2.4%, Al: 0.5%, Ti: 0.9%, Nb : 5.4%, V: 0.95%, C: 0.025%, and the balance is Fe. That

Embodiment 2

[0027] The mass percent of the chemical composition of the superalloy metallurgical blade of the present invention is preferably: Ni: 52.5%, Cr: 20.5%, Mo: 3.25%, Co: 0.55%, W: 2.6%, Al: 0.6%, Ti: 1.1%, Nb : 5.3%, V: 0.98%, C: 0.028%, and the balance is Fe.

Embodiment 3

[0029] The mass percent of the chemical composition of the superalloy metallurgical blade of the present invention is preferably: Ni: 53.1%, Cr: 19.0%, Mo: 3.4%, Co: 0.48%, W: 2.25%, Al: 0.65%, Ti: 1.0%, Nb : 5.34%, V: 0.90%, C: 0.035%, and the balance is Fe.

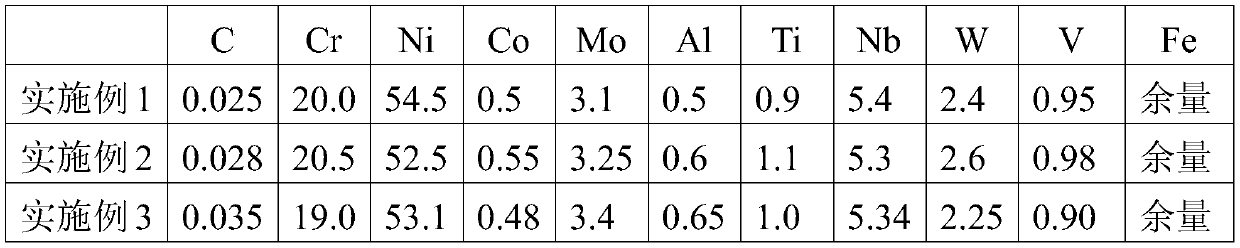

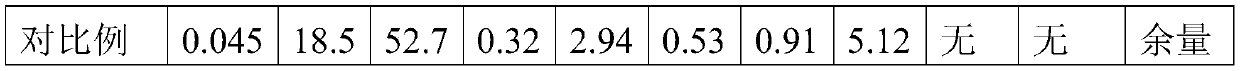

[0030] Table 1 shows the chemical composition mass percentages of the imported nickel-based alloys in the three embodiments of the present invention and the background technology.

[0031] Table 1. Composition of superalloy metallurgical blade materials (wt,%)

[0032]

[0033]

[0034] It can be seen from the above table that the chemical composition of the superalloy metallurgical blade of the present invention is characterized by containing more than ten kinds of elements, and the main advantages of the material of the superalloy metallurgical blade are: 1. Niobium is the main precipitation strengthening element, and the content is controlled at the upper limit; 2. Add W element in the alloy, and Mo+Co+W>5.5%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com