Non-contact device for detecting vibration of aircraft tail and method

A vibration detection, non-contact technology, used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as experimental errors and affect experimental accuracy, achieve uncomplicated structure, improve measurement accuracy, and reduce errors. Effect

Pending Publication Date: 2019-01-11

SOUTH CHINA UNIV OF TECH

View PDF11 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] So far, the mainstream vibration detection devices used for the study of aircraft tail buffeting mainly use piezoelectric sensors. This contact measurement method must have a load effect because the detection device is in direct contact with the measured object, so it is introduced into the experiment. error, which affects the accuracy of the experiment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

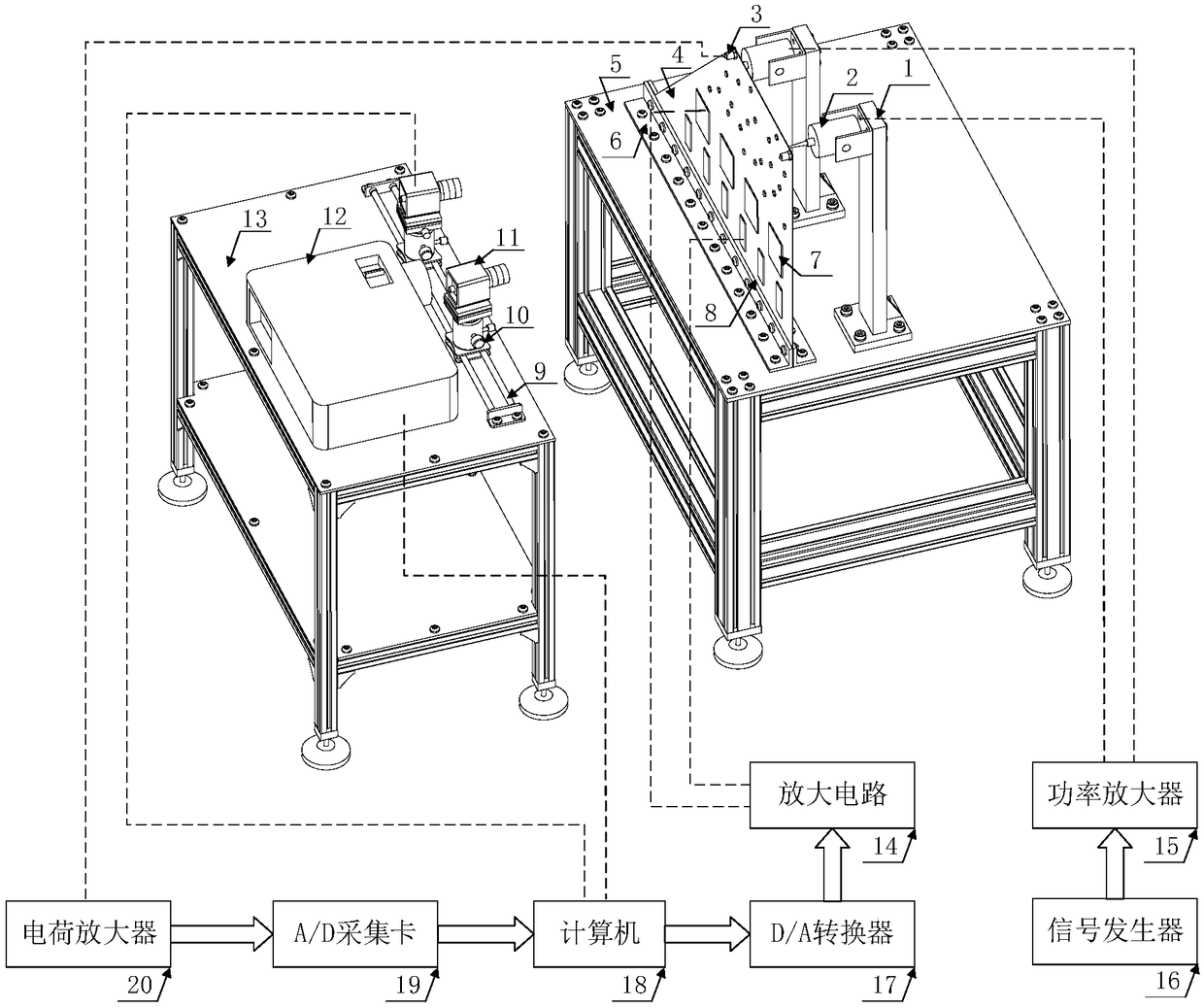

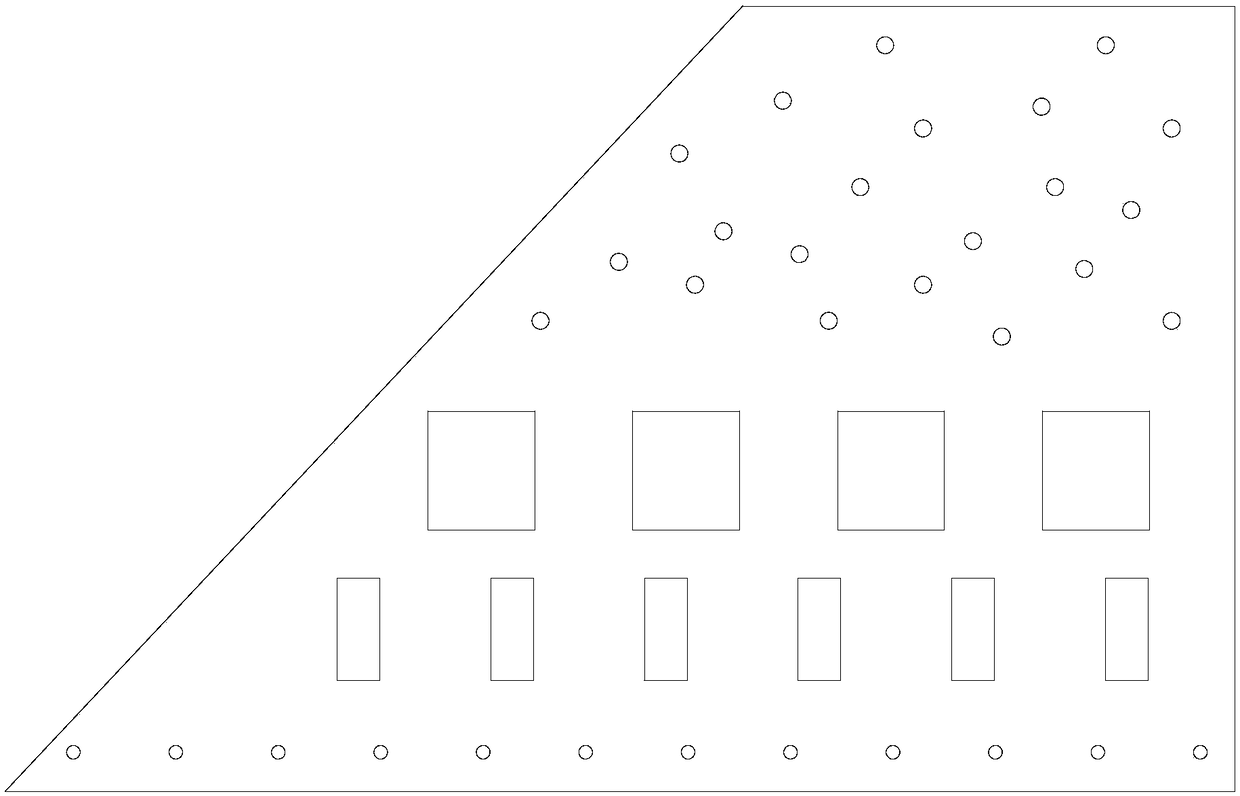

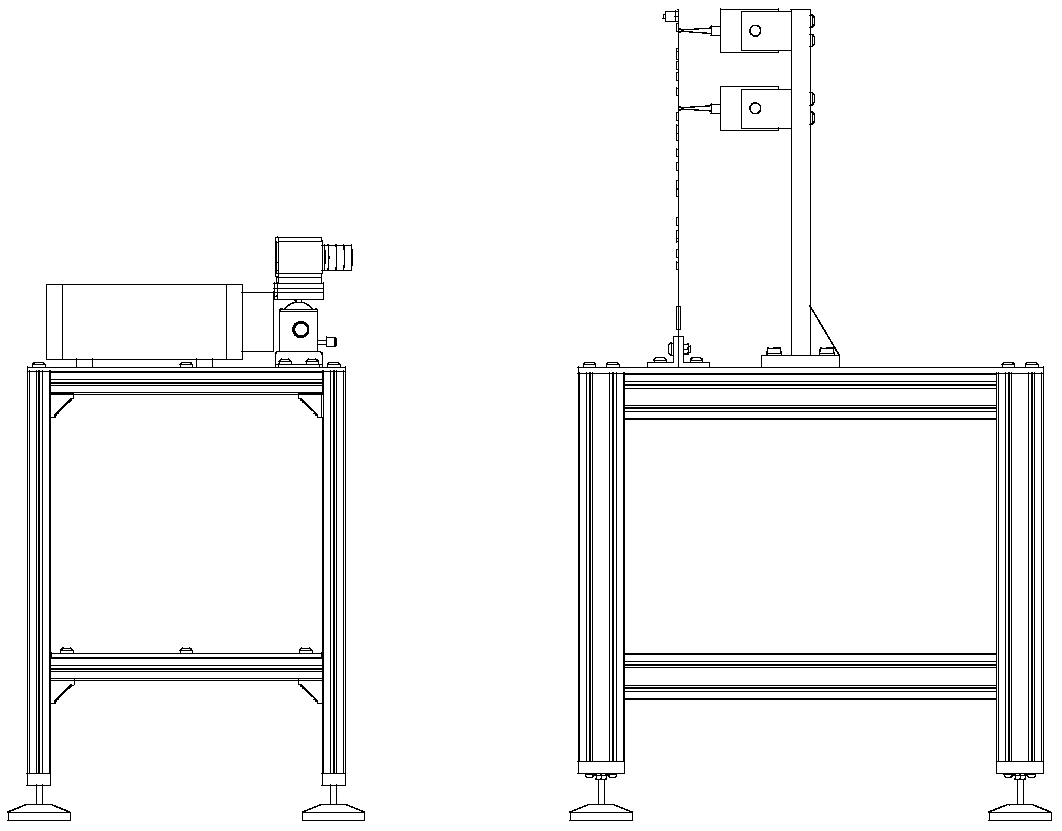

[0039] Such as Figure 1-Figure 5 Shown, a vibration detection device of a non-contact aircraft empennage comprises an aircraft empennage body part, an excitation part, a vibration detection part and a control part;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a non-contact device for detecting the vibration of an aircraft tail and a method. The device comprises an aircraft tail body portion, an excitation portion, a vibration detecting portion and a control portion. The aircraft tail body portion comprises an aircraft tail structure. The excitation portion comprises an exciter, a signal generator, and a power amplifier. The vibration detecting portion comprises a projector, an accelerometer, and a CCD camera. The control portion comprises a piezoelectric ceramic driver, a torsional modal driver, an amplifying circuit, and aD / A converter. According to the non-contact device for detecting the vibration of an aircraft tail and the method, the measurement and control of the vibration of the aircraft tail body portion are realized.

Description

technical field [0001] The invention relates to the field of vibration control of an aircraft empennage, in particular to a vibration detection device and method for a non-contact aircraft empennage. Background technique [0002] Empennage is a device installed on the tail of an aircraft to enhance the stability of the aircraft during flight. One of the damages aircraft tails face during flight is tail buffeting. Aircraft, especially fighter jets, form buffeting when the airflow diffuses through the fuselage and wings at high angles of attack. Buffeting is defined as the irregular vibration of the aircraft structure caused by turbulence. The high-intensity eddy current load will be formed during the flight of the aircraft. This vortex will increase the lift when it passes through the wings and fuselage, but when it encounters the aircraft empennage Occasionally, high-energy turbulent impacts will be generated on the empennage structure, and long-term impacts will form cont...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01H9/00

CPCG01H9/00

Inventor 邱志成黄子骞

Owner SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com