Intravascular metal fully degraded high throughput simulation monitoring system based on micro-fluidic chip

A microfluidic chip and monitoring system technology, applied in the direction of applying stable shear force to test the strength of materials, measuring devices, testing wear resistance, etc., can solve the problems of low throughput and long test cycle of evaluation methods, etc. Achieve the effect of speeding up the experiment progress, shortening the research cycle, and solving the long experiment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

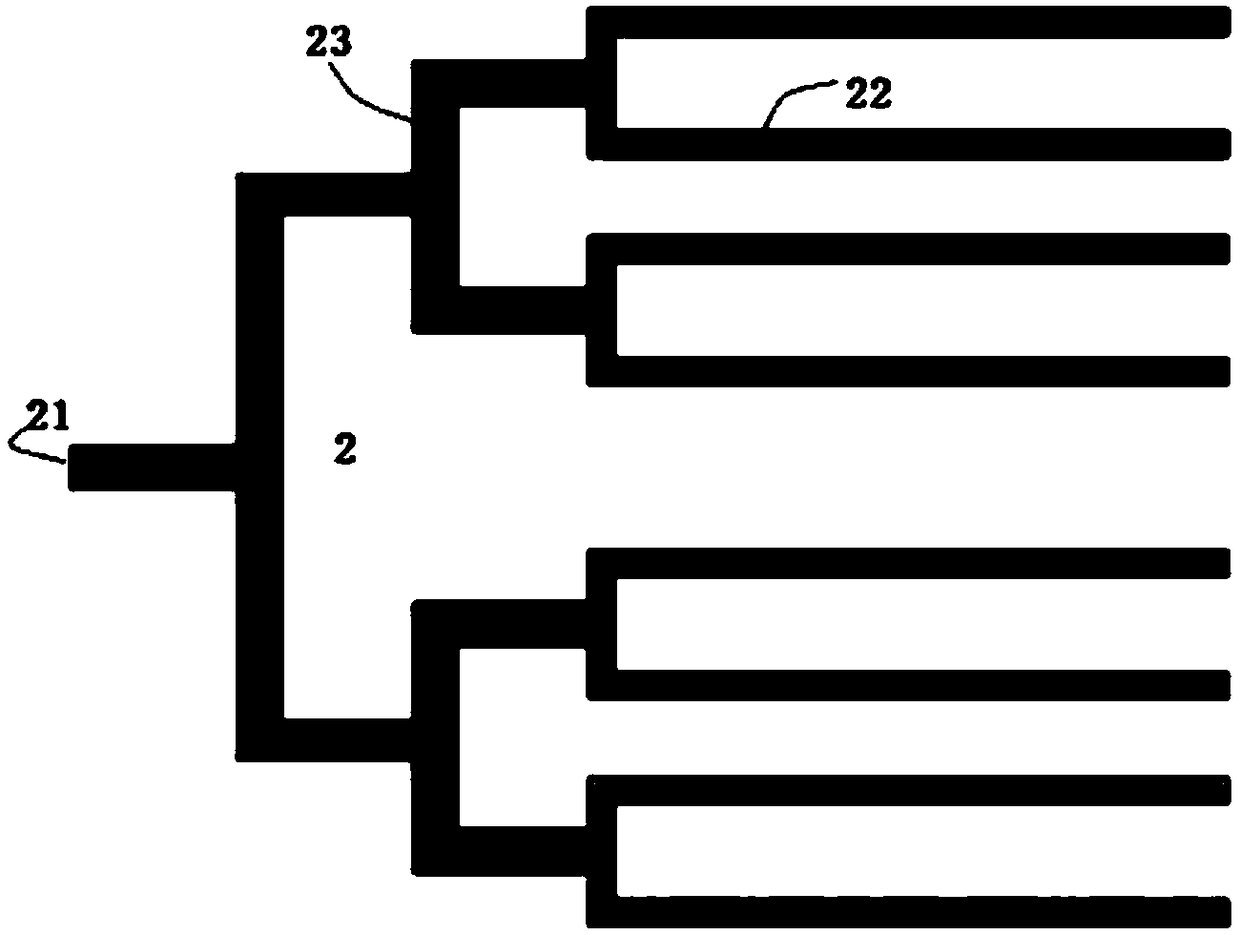

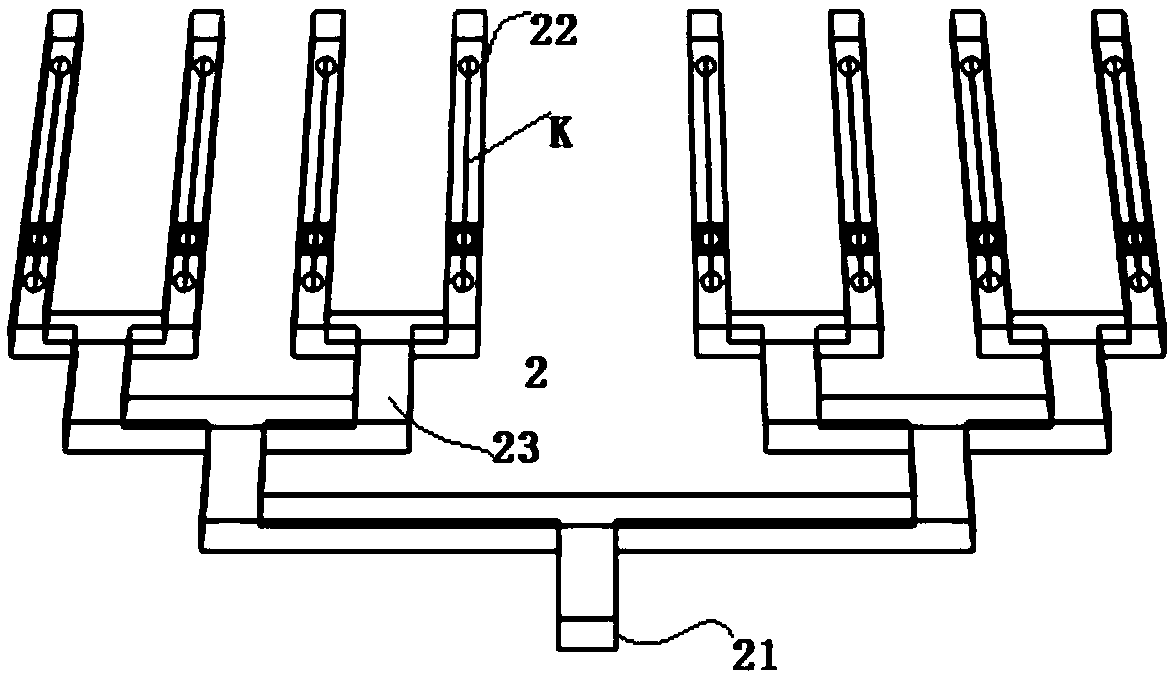

[0028] Embodiment 1 (8-channel microfluidic chip):

[0029] The multi-channel microfluidic chip set 2 is a polydimethylsiloxane (PDMS) microfluidic chip, which is formed by bonding a polydimethylsiloxane (PDMS) layer with a microchannel structure and a glass sheet, The PDMS layer height was 4 mm. The surface of the PDMS layer is processed with a microchannel structure, the width of the fluid distribution channel 23 is 400 microns, the width a of the full degradation metal degradation reaction channel 22 is 240 microns, and the height b of the two channels is uniformly 240 microns, so S1=a* b = 57600 microns 2 . The diameter D of the full-degradation metal wire matched with the full-degradation reaction channel of the chip of this embodiment is 160 microns, so S2=π*(D / 2)2=6400π microns 2 , P=S1 / S2=9 / π. Corresponding to the flow rate of the inlet port 21 of the microfluidic chip is 0.72mL / min, it is calculated that the flow rate of the degradation reaction channel is about 0...

Embodiment 2

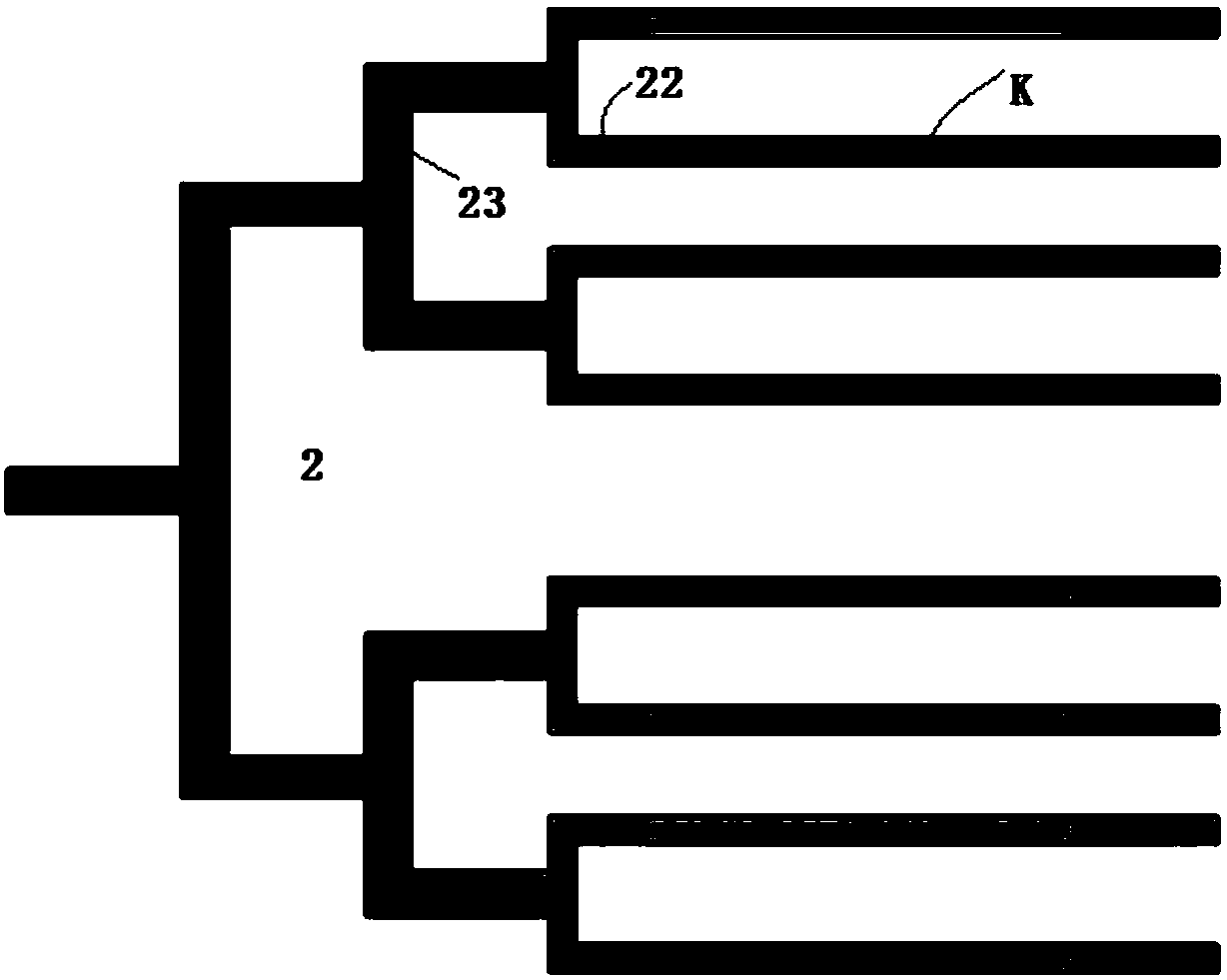

[0033] Embodiment 2 (4-channel microfluidic chip):

[0034] In this embodiment, only the microfluidic chip in embodiment 1 is replaced with a 4-channel microfluidic chip, and the rest of the content is the same as in embodiment 1. The significance of this example is to illustrate that the number of channels of the microfluidic chip can be determined according to the number of actual experimental samples, and is not limited to that described in Example 1, so as to improve the experimental efficiency. The channels of the microfluidic chip appear in the field of view of the microscope.

[0035] When applying the present invention to simulate the fluid shear stress in the blood vessel to study the action behavior of the fully degraded metal degradation behavior, the following steps can be carried out:

[0036] Prepare a microfluidic chip and a fully degradable metal wire with matching sizes, implant the fully degradable metal wire into the degradation reaction channel of the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com