Rapid detection box for metal working liquid

A metalworking fluid and detection box technology, applied in the field of detection, can solve the problems of limited feedback data and insufficient detection of metalworking fluids, and achieve the effects of increasing compatibility, increasing functional diversification, and fast detection speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

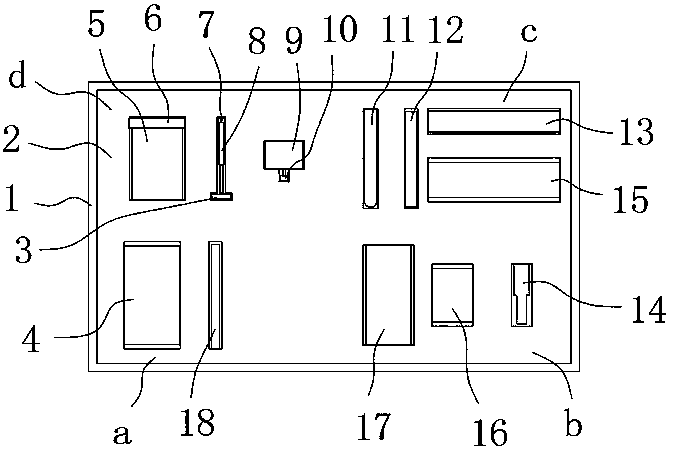

[0028] use figure 1 It shows the rapid detection box, wherein a detection area includes two first installation slots parallel to and perpendicular to the bottom side wall of the upper box body 1, one of the first installation slots is installed with a rinse bottle 4, and the other second installation slot holds A refractometer 18 is connected.

[0029] Take metalworking fluids that have been used for 1, 2, 3, 4, and 5 months as samples, and then use the refractometer 18 to detect the concentration in each sample to record multiple sets of data.

[0030] Analyze whether the metalworking fluid is qualified according to the concentration of the detected sample.

Embodiment 2

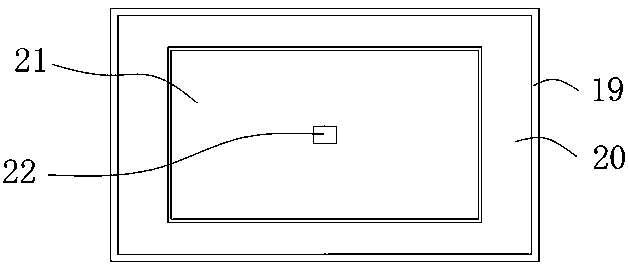

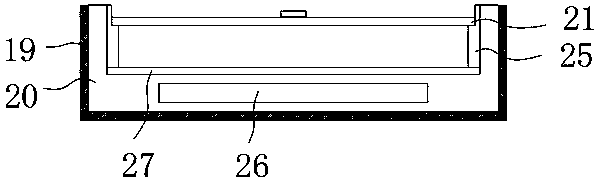

[0032] use figure 1 It shows a quick detection box, wherein b detection area has three second installation slots parallel to and perpendicular to the bottom side wall of the upper box body 1, the second installation slot on the left side is equipped with a weak acid solution bottle 17, and the second installation slot on the right side is installed The groove is equipped with a glue head dropper 14, and the second installation groove in the middle is equipped with a chip box 16. In addition, the constant temperature device includes a constant temperature chamber, which is set in the heat insulation board 20, and the heat preservation cover 21 is installed in the constant temperature chamber. A pull pin 22 is fixedly connected to one side of the constant temperature cavity, and a thermal insulation board 25 is installed on the side walls around the constant temperature chamber. A battery pack 26 is arranged inside the thermal insulation board 20. The battery pack 26 is composed ...

Embodiment 3

[0036] use figure 1 shows a quick detection box, wherein the c detection area includes two third installation grooves arranged parallel to and perpendicular to the bottom side wall of the upper box body 1 and two fourth installation grooves arranged parallel to the bottom side wall of the upper box body 1, wherein A test tube 11 is installed in a third installation groove, tweezers 12 are installed in the other third installation groove, a color comparison card 13 is installed in one of the fourth installation grooves, and a detection test paper 15 is installed in the other fourth installation groove.

[0037] Take the current metalworking fluid into the test tube 11, and then take out the detection test paper 15, which is a pH test paper, use the tweezers 12 to clamp the pH test paper, then put it into the test tube 11, let the tweezers 12 rotate, so that the detection test paper 15 is constantly swinging in the metal working fluid, allowing it to fully contact the metal work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com