Method for preparing and using electrochemical immunosensor for aflatoxin B1 detection

An immune sensor and aflatoxin technology, applied to scientific instruments, instruments, measuring devices, etc., can solve the problems of high cost, poor effect, and great harm, and achieve short response time, increased specific surface area, and low detection cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

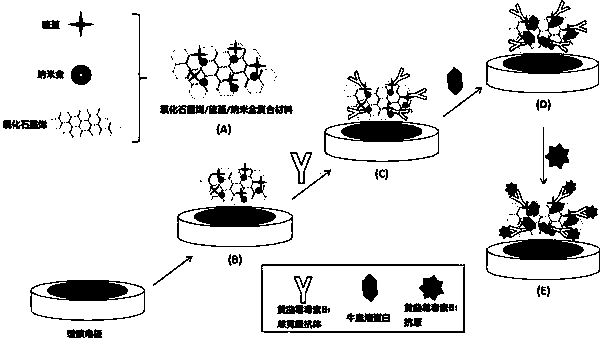

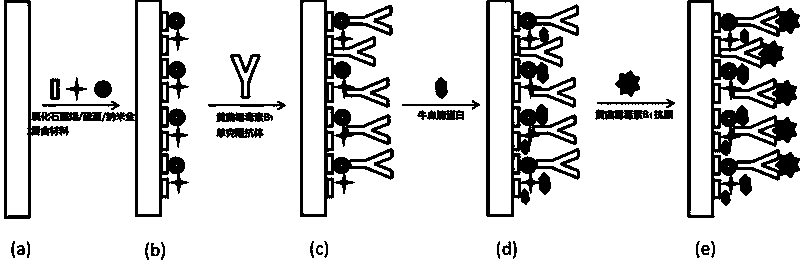

[0029] 1. The preparation of the electrochemical immunosensor is as follows:

[0030] Prepare nano gold solution, then the concentration of 1 volume part A1 is the graphene oxide of 1.01wt%, the nano gold solution of the thionine of 1 weight part B1, 8.333 volume parts A1 is placed in band cap weighing bottle, 1 volume part The relationship between A1 and 1 part by weight of B1 is: 1 ml corresponds to 1.25 mg. A stirring magnet is placed in the weighing bottle. After the weighing bottle is capped, it is placed on a magnetic stirring table and stirred for about 4 hours to fully mix the materials in the bottle to obtain oxidation. Graphene / thionine / nano-gold composite material, stored at 4°C, drop 1 volume part of A2 graphene oxide / thionine / nano-gold composite material 2S on the surface of the activated glassy carbon electrode, and then place the glassy carbon electrode on Store in a refrigerator at 4°C for 12 hours until the surface of the glassy carbon electrode forms a solid ...

Embodiment 2

[0041] 1. The preparation of the electrochemical immunosensor is as follows:

[0042] Prepare nano-gold solution, then the concentration of 1 volume part A1 is the graphene oxide of 0.5wt%, the thionine of 1 weight part B1, the nano-gold solution of 5 volume parts A1 is placed in band cap weighing bottle, 1 volume part The relationship between A1 and 1 part by weight of B1 is: 1 milliliter corresponds to 1 milligram. A stirring magnet is placed in the weighing bottle. After the weighing bottle is capped, it is placed on a magnetic stirring table and stirred for about 4 hours to fully mix the materials in the bottle to obtain oxidation. Graphene / thionine / nano-gold composite material, stored at 2°C, drop 1 volume part of A2 graphene oxide / thionine / nano-gold composite material 1S on the surface of the activated glassy carbon electrode, and then place the glassy carbon electrode on Store in a refrigerator at 2°C for 10 hours until the surface of the glassy carbon electrode forms a...

Embodiment 3

[0053] 1. The preparation of the electrochemical immunosensor is as follows:

[0054] Prepare nano-gold solution, then the concentration of 1 volume part A1 is the graphene oxide of 1.5wt%, the thionine of 1 weight part B1, the nano-gold solution of 12 volume parts A1 is placed in band cap weighing bottle, 1 volume part The relationship between A1 and 1 part by weight of B1 is: 1 ml corresponds to 5 mg. A stirring magnet is placed in the weighing bottle. After the weighing bottle is capped, it is placed on a magnetic stirring table and stirred for about 4 hours to fully mix the materials in the bottle to obtain oxidation. Graphene / thionine / nano-gold composite material, stored at 8°C, 1 volume part of A2 graphene oxide / thionine / nano-gold composite material 3S was dropped on the surface of the activated glassy carbon electrode, and then the glassy carbon electrode was placed Store in a refrigerator at 8°C for 14 hours until the surface of the glassy carbon electrode forms a soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com