A FPC coil structure with varying copper foil line width

A coil and line width technology, applied in the field of FPC coil structure, can solve problems such as large proximity effect, reduced transmission efficiency, and large magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

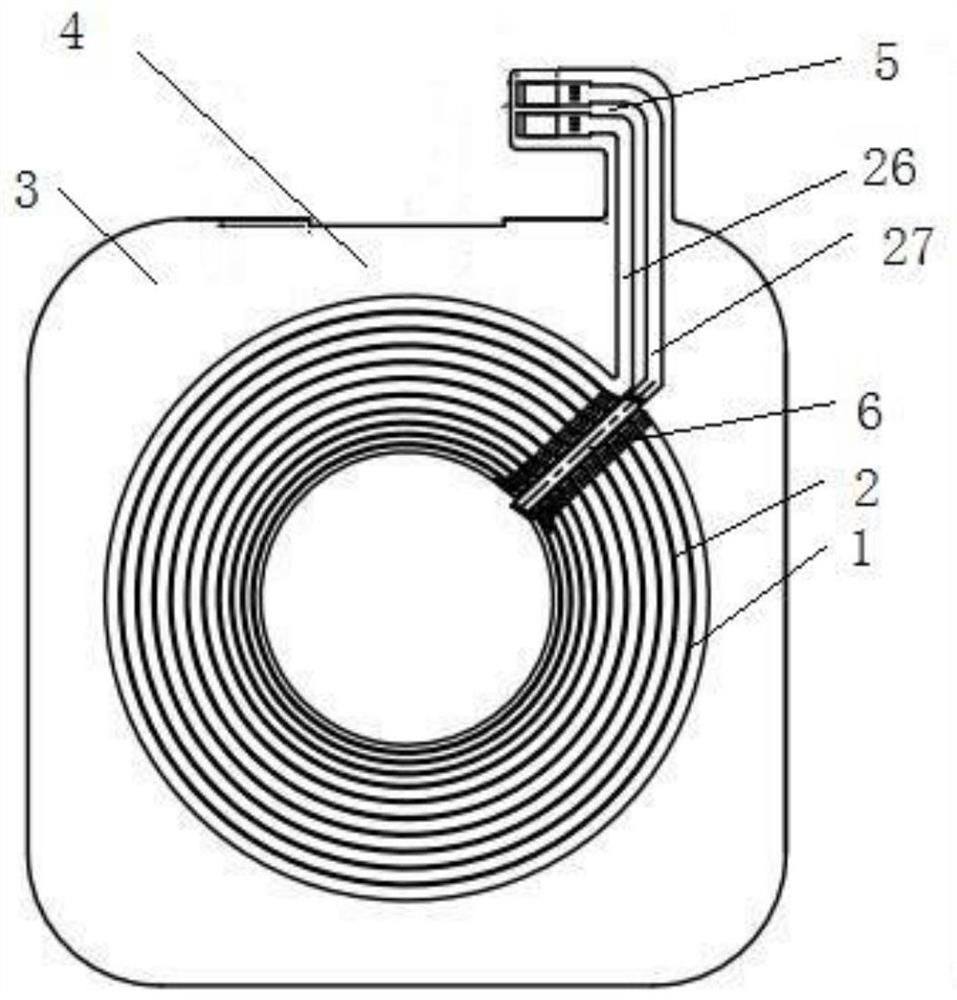

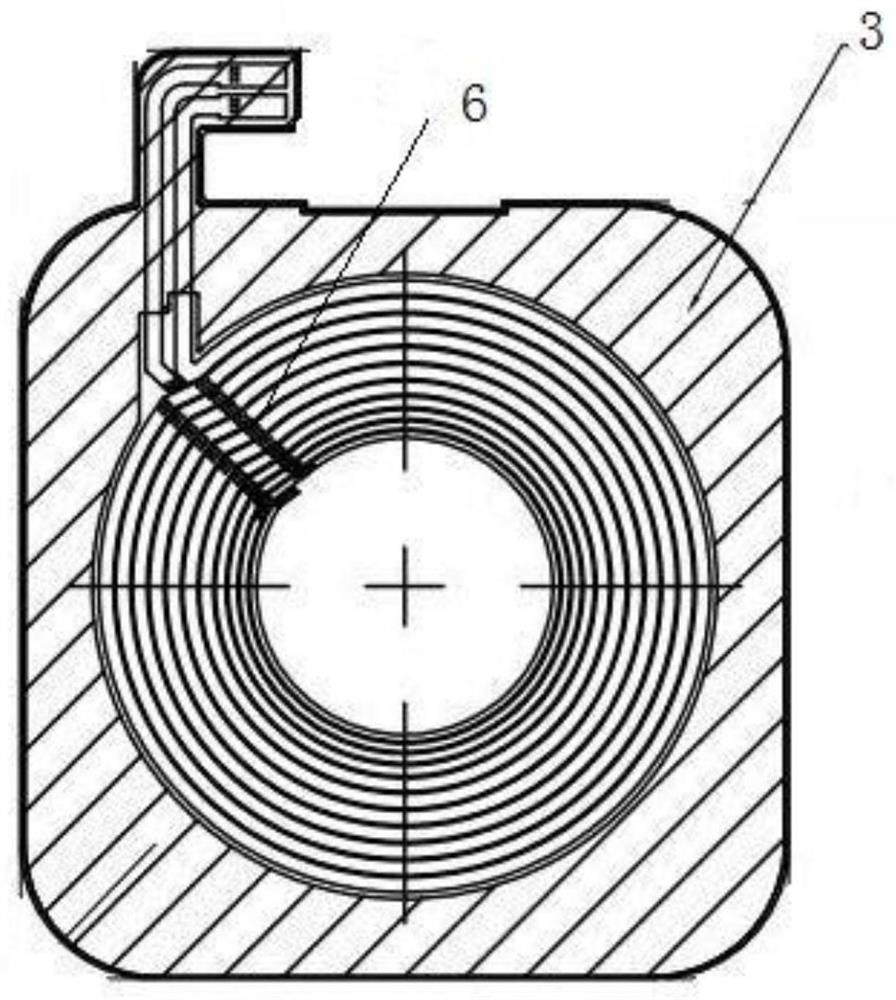

[0030] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a FPC coil structure with variable copper foil line width, comprising: a coil 2 having n turns of coil layer 1, and the width of the coil layer decreases layer by layer from the inside out. The width of any one turn of the coil layer is 0.4-1 mm. The FPC coil structure with variable copper foil line width also includes an FPC fixing plate 3 on which the coil is installed, and a protective film area 4 is installed on the fixing plate outside the coil. A protruding pad 5 is provided on one side of the FPC fixing board. The coil also has a wire slot 6 extending radially, and the coil has a wire outlet 26 and a wire inlet 27, and the wire outlet or wire inlet is installed in the wire slot. The terminal of the outgoing wire or the incoming wire is fixed in the welding pad.

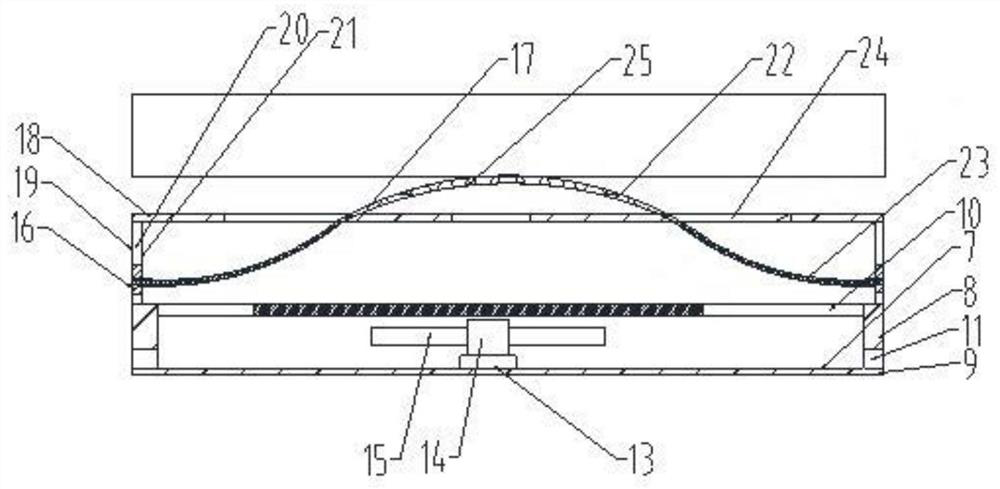

[0031] The FPC coil structure with variable copper foil line width also includes a base 7, the base includes a side w...

Embodiment 2

[0034] The present invention provides an FPC coil structure with variable copper foil line width, comprising: a coil with n turns of coil layers, the width of the coil layers decreases layer by layer from the inside out. The invention can optimize the size of the resistance by changing the line width of the coil. Reduce the AC resistance as much as possible, thereby changing the energy loss.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com