Hippophae rhamnoides fruit bovine coloctrum powder and production method thereof

A technology of bovine colostrum powder and production method, which is applied in the field of dairy product processing, can solve the problems of insufficient milk flavor, thin texture, and poor satiety, and achieve the effects of improving flavor, thick texture, and strong satiety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The present embodiment provides a kind of seabuckthorn bovine colostrum powder, comprising the raw materials of following mass concentration: bovine colostrum 46%, raw milk 21%, seabuckthorn juice 22%, vanilla extract 1.5%, honey 4%, citric acid 0.3%, 0.3% of monoglyceryl stearate, 0.4% of ascorbyl palmitate, 0.5% of lecithin, 2% of mannitol, and 2% of trehalose; the pH of the bovine colostrum is 5.95, and the density is 1.052.

[0020] The production method of described seabuckthorn bovine colostrum powder comprises the steps:

[0021] (1) Let the bovine colostrum stand at -3°C for 16 hours, filter the bovine colostrum three times with clean cotton gauze; use a ceramic flat membrane with a pore size of 3um to perform cross-flow filtration on the obtained filtrate, and collect the permeable membrane liquid;

[0022] (2) Use an electron accelerator to irradiate and sterilize the permeable liquid, raw milk and seabuckthorn juice respectively, and the absorbed dose is 6KG...

Embodiment 2

[0027] Adopt the production method of Example 1, the difference is: the seabuckthorn bovine colostrum powder includes raw materials with the following mass concentrations: bovine colostrum 42%, raw milk 26%, seabuckthorn juice 25%, vanilla extract 2%, 0.5% citric acid, 0.2% monoglyceride stearate, 0.3% ascorbyl palmitate, 0.5% lecithin, 2% mannitol, 2% trehalose; the pH of the bovine colostrum is 6.03, and the density is 1.044.

Embodiment 3

[0029] Adopt the production method of Example 1, the difference is: the seabuckthorn bovine colostrum powder includes raw materials with the following mass concentrations: bovine colostrum 50%, raw milk 18%, seabuckthorn juice 22%, vanilla extract 1%, Honey 3%, citric acid 0.5%, monoglyceryl stearate 0.4%, ascorbyl palmitate 0.4%, lecithin 0.5%, mannitol 1.7%, trehalose 2.5%; the pH of the bovine colostrum is 5.92, Density 1.057.

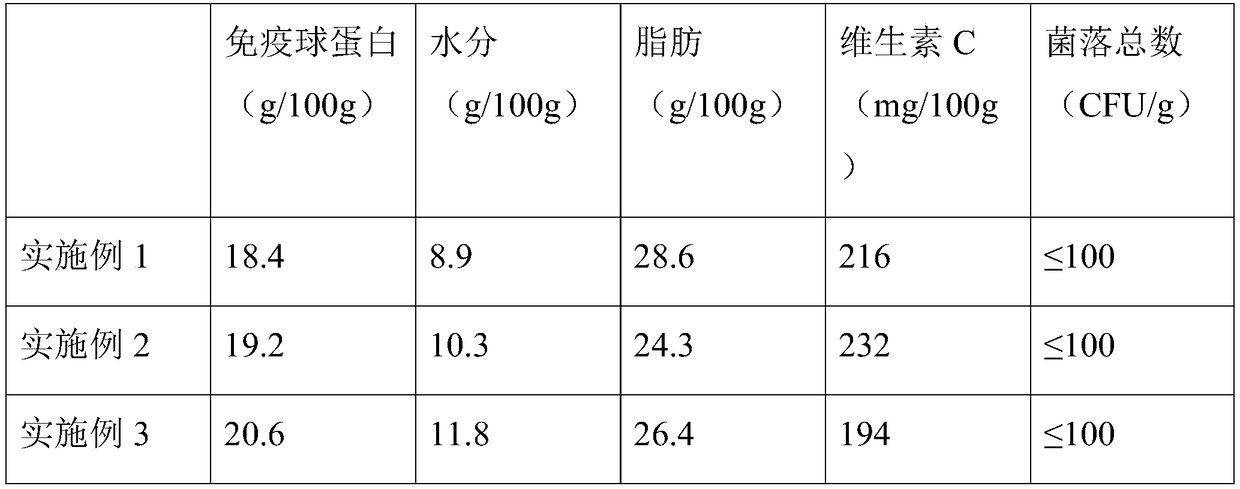

[0030] Check the main components and content thereof of embodiment 1-3 gained lyophilized powder, the results are shown in table 1 below:

[0031] Table 1: Main components and contents of freeze-dried powder

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com