Soy sauce flavor substance and preparation method and application thereof

A technology for flavor and substance of soy sauce, applied in the field of condiments, can solve the problems of large output of soy sauce residue, waste of resources, environmental pollution, etc., and achieve the effects of low cost, strong controllability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

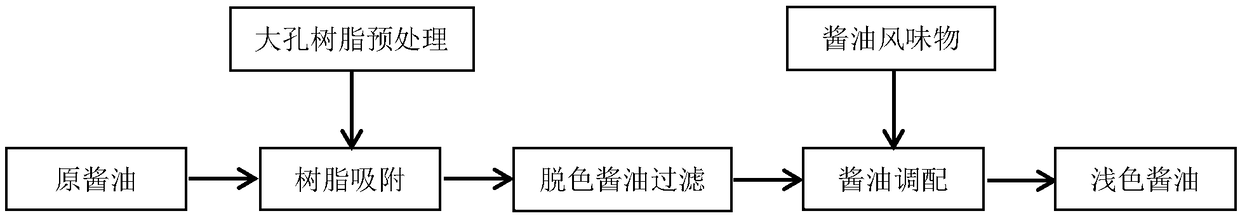

Method used

Image

Examples

Embodiment 1

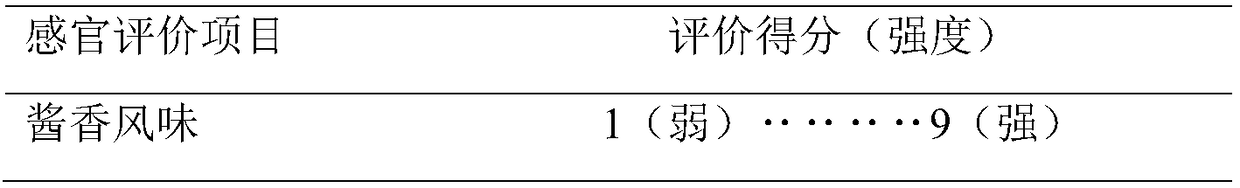

[0043] Study on the preparation method of soy sauce flavor substances.

[0044] 1. Test method.

[0045] After the brewing of soy sauce is completed, the soy mash is gravity pressed to extract the soy sauce, and the remaining residue is the soy sauce residue, and the moisture content is controlled at 26%-30%.

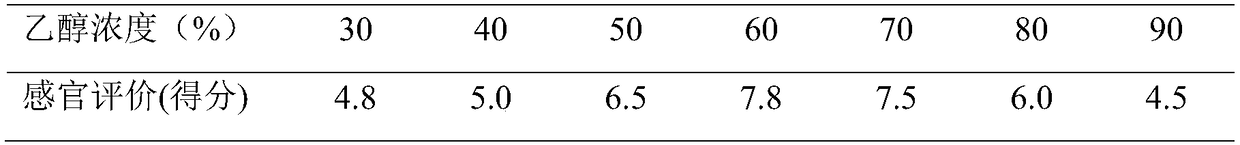

[0046] After the soy sauce residue is crushed into particles with a particle diameter of 8-12 mm, the volume percentage of ethanol aqueous solution is 30%, 40%, 50%, 60%, 70%, 80%, 90%, and the solid-liquid ratio (w / v) is 1:3, 1:4, 1:5, 1:6, 1:7, 1:8, 1:9, and the extraction time is 2 days, 4 days, 6 days, 8 days, 10 days, Under the conditions of 12 days and 14 days, the flavor of soy sauce was extracted respectively. After the extraction, the extract was distilled at atmospheric pressure, and the distillate was recovered through a condensation process. The distilled solution was ethanol containing soy sauce flavor. The solution has a strong aroma of soy sauce, and t...

Embodiment 2

[0069] A composition for adding soy sauce flavor, comprising: soy sauce flavor substances, salt, sweetener and umami agent.

[0070] Wherein, the soy sauce flavor substance is prepared by the following method: take soy sauce residue, and control the water content at 26%-30%. After the soy sauce residue is crushed into particles with a particle size of 8-12mm, the selected solvent is 60% ethanol aqueous solution with a solid-liquid ratio (w / v) of 1:5, sealed and extracted at room temperature, and the extraction time is 1 day For 7 days, the soy sauce flavor is extracted. After the extraction is completed, the extract is distilled at atmospheric pressure, and the distillate is recovered through a condensation process. The alcohol concentration can be controlled at 50%-70%; the distilled solution contains The ethanol solution of the soy sauce flavor substance has a strong soy sauce aroma, and the soy sauce flavor substance is obtained.

[0071] The raw material weight ratio of t...

Embodiment 3

[0074] Screening of macroporous resins.

[0075] 1. Test method

[0076] 1.1 Pretreatment of macroporous resin

[0077] Weigh a certain amount of macroporous resin, wash it with distilled water until there is no turbidity, and then filter off the water. Then soak with 5% hydrochloric acid solution and 5% sodium hydroxide solution about 2 times the volume of the macroporous resin for 6 hours respectively, and wash the resin with distilled water until neutral. Finally, soak in ethanol with a volume fraction of 95% for 6 hours, wash with distilled water until there is no ethanol smell, and filter off the water for later use.

[0078] 1.2 Decolorization of macroporous resin

[0079] Weigh 20g of the pretreated resin into a 250mL Erlenmeyer flask, add 100g of soy sauce, place in a constant temperature shaking box, adjust the temperature to 30°C, shaker speed to 150r / min, shake and decolorize for 3h. After the decolorization is finished, filter with a 200 mesh sieve and collect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com