A kind of preparation method of peptide-rich soy sauce

A soy sauce and peptide-rich technology, which is applied in the field of food processing, can solve the problems of no obvious effect, and achieve the effect of strong soy sauce aroma, delicious taste and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

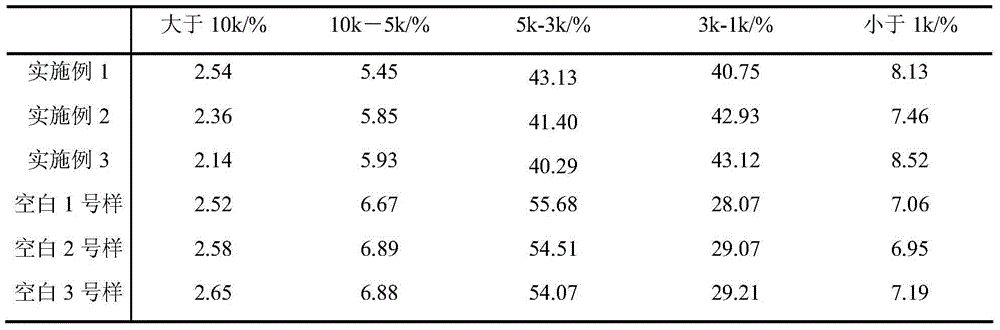

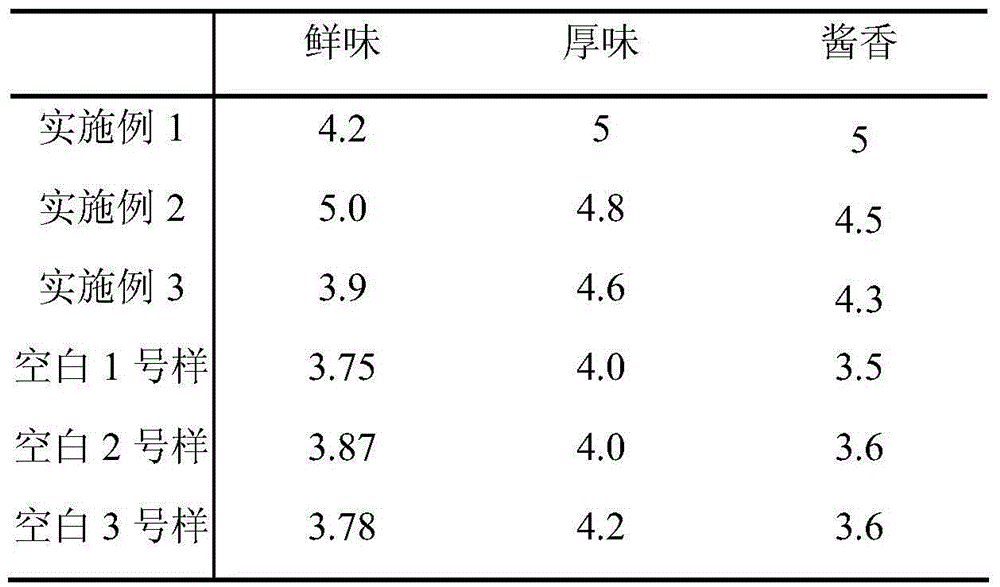

Examples

Embodiment 1

[0027] (1) Mix 1 part by mass of soybean meal with 8 parts by mass of water, treat at 90°C for 30 minutes, add 0.03 parts of Novozymes' flavor protease (Flavorzyme) to hydrolyze until the degree of hydrolysis of soybean protein is 30.2%, heat treat at 80°C for 30 minutes to inactivate the enzyme , to obtain soybean protein hydrolyzate.

[0028] (2) 1 mass part of soybean meal is cooked at 125°C for 5 minutes, mixed with 1 mass portion of flour, cooled and inoculated with Aspergillus oryzae koji essence of 0.02% (w / w) of soybean meal weight, cultured at 28°C and 95% humidity, The culture time is 40h, and the koji is obtained;

[0029] (3) Mix Daqu with 4 times the weight of soybean protein hydrolyzate, ferment for 60 days using the high-salt dilute soy sauce brewing method (GB18186-2000), squeeze and filter to obtain the soy sauce stock solution.

[0030] The fermentation process of the blank soy sauce sample is:

[0031] (1) 1 mass part of soybean meal was cooked at 125°C fo...

Embodiment 2

[0034] (1) Mix 1 times the weight of concentrated soybean protein with 8 parts of water, treat at 90°C for 30 minutes, add 0.05 part of umami protease (Amano company) to hydrolyze until the degree of hydrolysis of soybean protein is 36.1%, heat treat at 95°C for 20 minutes to inactivate the enzyme, and obtain soybeans protein hydrolyzate.

[0035] (2) 1 part by mass of soybean meal was cooked at 125°C for 5 minutes, mixed with 0.6 part by mass of flour, cooled and then inoculated with Aspergillus oryzae koji essence of 0.04% (w / w) of soybean meal weight, cultured at 25°C and 95% humidity, The culture time is 60h, and the koji is obtained;

[0036] (3) Mix Daqu with 2 times the weight of soybean protein hydrolyzate, ferment for 60 days using the high-salt dilute soy sauce brewing method (GB18186-2000), squeeze and filter to obtain the soy sauce stock solution.

[0037] The fermentation process of the blank soy sauce sample is:

[0038] (1) 1 part by mass of soybean meal was c...

Embodiment 3

[0041] (1) Mix 1kg soybean protein isolate with 15kg water evenly, treat at 90°C for 30 minutes, add 60g of fungal protease concentrate (Genencor) to hydrolyze until the degree of hydrolysis of soybean protein is 39.6%, heat-treat at 85°C for 25 minutes to inactivate the enzyme, and obtain soybean protein hydrolyzate ;

[0042] (2) 1 part by mass of soybeans was cooked at 125°C for 5 minutes, mixed with 1 part by mass of flour, cooled and then inoculated with Aspergillus oryzae koji essence of 0.08% (w / w) of soybean weight, cultured at 28°C and 95% humidity, The culture time is 40h, and the koji is obtained;

[0043] (3) Mix Daqu with 3 times the weight of soybean protein hydrolyzate, ferment for 60 days using the high-salt dilute soy sauce brewing method (GB18186-2000), squeeze and filter to obtain the soy sauce stock solution.

[0044] The fermentation process of the blank soy sauce sample is:

[0045] (1) 1 mass part of soybean meal or soybean is cooked at 125°C for 5 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com