Method for preparation of alpha-olefin by ethylene oligomerization

A technology for ethylene oligomerization and olefins, applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, hydrocarbons, etc., to achieve the effects of avoiding the formation of high polymers, reasonable distribution, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

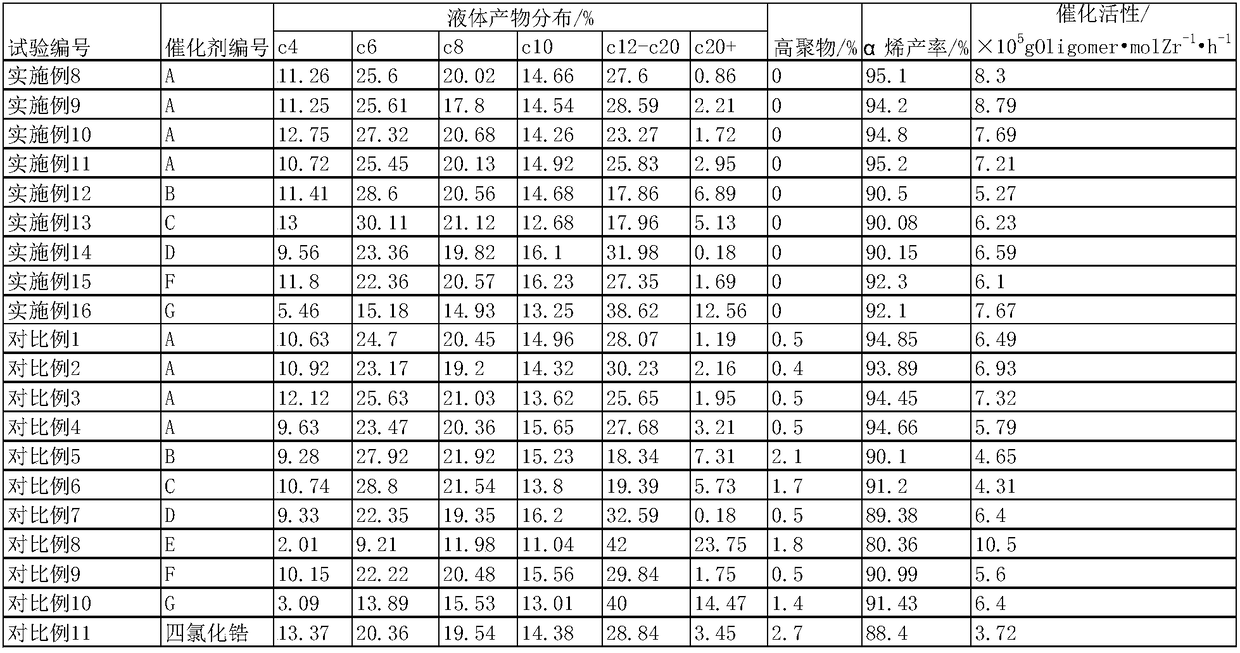

Examples

Embodiment 1

[0054] This example illustrates the preparation of an ethylene oligomerization catalyst.

[0055] 2.33g (10mmol) ZrCl 4 Place in a three-necked flask, add 30 mL of toluene, heat to 70°C, reflux and stir for 1 hour, add 2.85 mL (30 mmol) of 1,3-dichloro-2-propanol dropwise, continue to reflux for 4 hours, cool down, and place in an ice-water bath 3.82mL (30mmol) trimethylchlorosilane was added dropwise under the condition, reacted for 4 hours, and toluene was added until the solution was 50mL to obtain an oligomerization catalyst solution A with a zirconium concentration of 0.2 mol / liter.

Embodiment 2

[0057] This example illustrates the preparation of an ethylene oligomerization catalyst.

[0058] The same method as in Example 1 was adopted, except that 3.0 mL (30 mmol) of 4-chloro-1-butanol was used instead of 1,3-dichloro-2-propanol to prepare catalyst solution B.

Embodiment 3

[0060] This example illustrates the preparation of an ethylene oligomerization catalyst.

[0061] The same method as in Example 1 was adopted, except that 3.75 mL (30 mmol) of heptafluorobutanol was used instead of 1,3-dichloro-2-propanol to prepare catalyst solution C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com