Outer wall leveling putty and preparation method thereof

A technology for exterior walls and components, applied in the direction of filling slurry, etc., can solve the problems of low bonding strength of putty, lack of humidity control ability, bulging coating layer, etc., achieving good workability and filling and leveling performance, and easy mass production. and promotion, the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A leveling putty for external walls, including component 1 and component 2, wherein component 1 is a powder part, and component 2 is a liquid part:

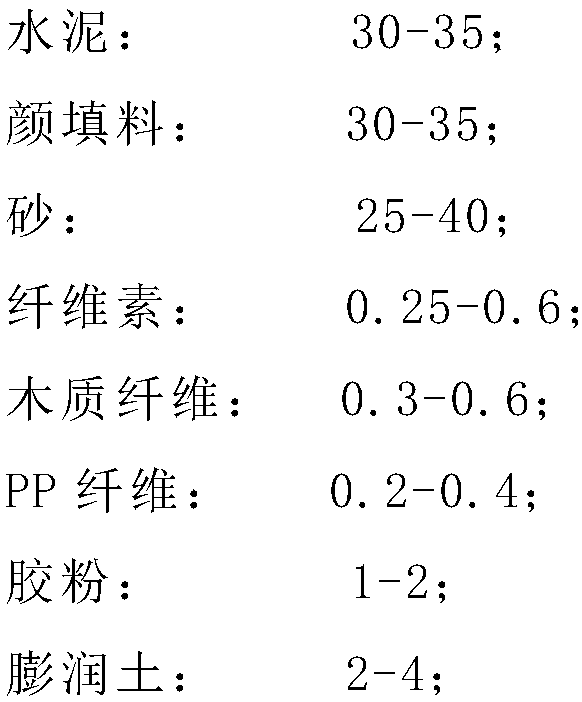

[0024] Described component one is made up of each material of following mass parts:

[0025]

[0026] Described component two comprises each material of following mass parts:

[0027]

[0028] The mass ratio of component one to component two is 1:0.32.

Embodiment 2

[0030] A leveling putty for external walls, including component 1 and component 2, wherein component 1 is a powder part, and component 2 is a liquid part:

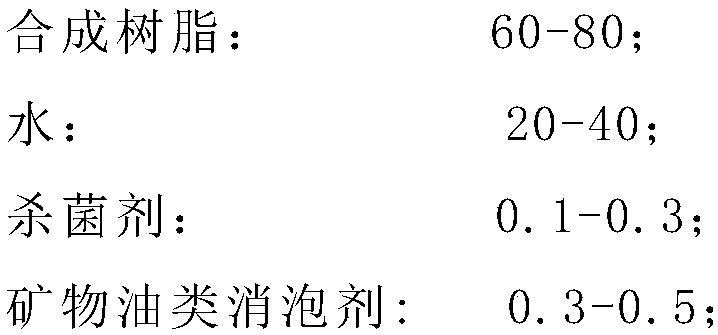

[0031] Described component one is made up of each material of following mass parts:

[0032]

[0033] Described component two comprises each material of following mass parts:

[0034]

[0035]

[0036] The mass ratio of component one to component two is 1:0.3.

Embodiment 3

[0038] A leveling putty for external walls, including component 1 and component 2, wherein component 1 is a powder part, and component 2 is a liquid part:

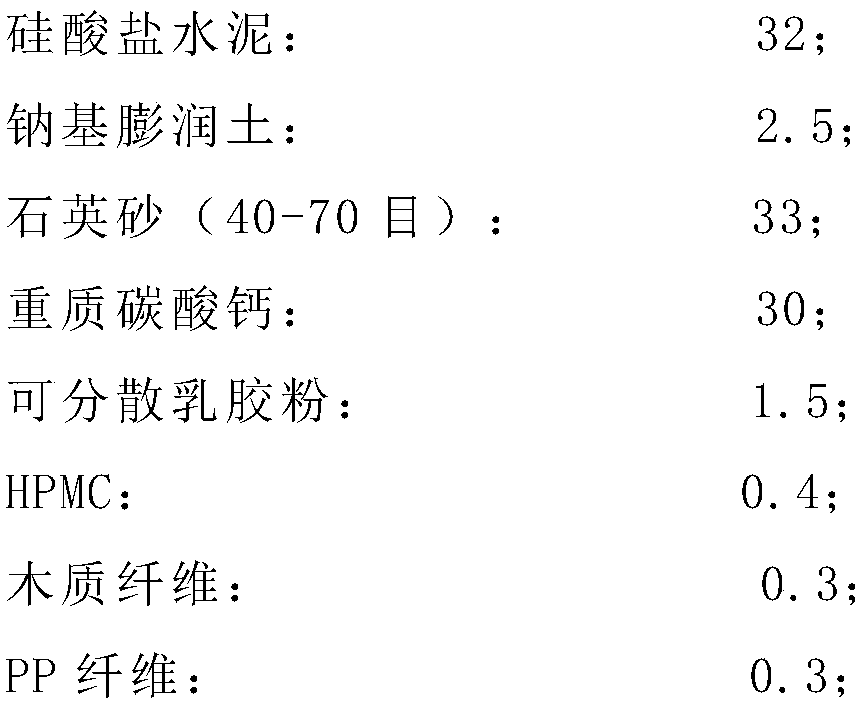

[0039] Described component one is made up of each material of following mass parts:

[0040]

[0041] Described component two comprises each material of following mass parts:

[0042]

[0043] The mass ratio of component one to component two is 1:0.34.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com