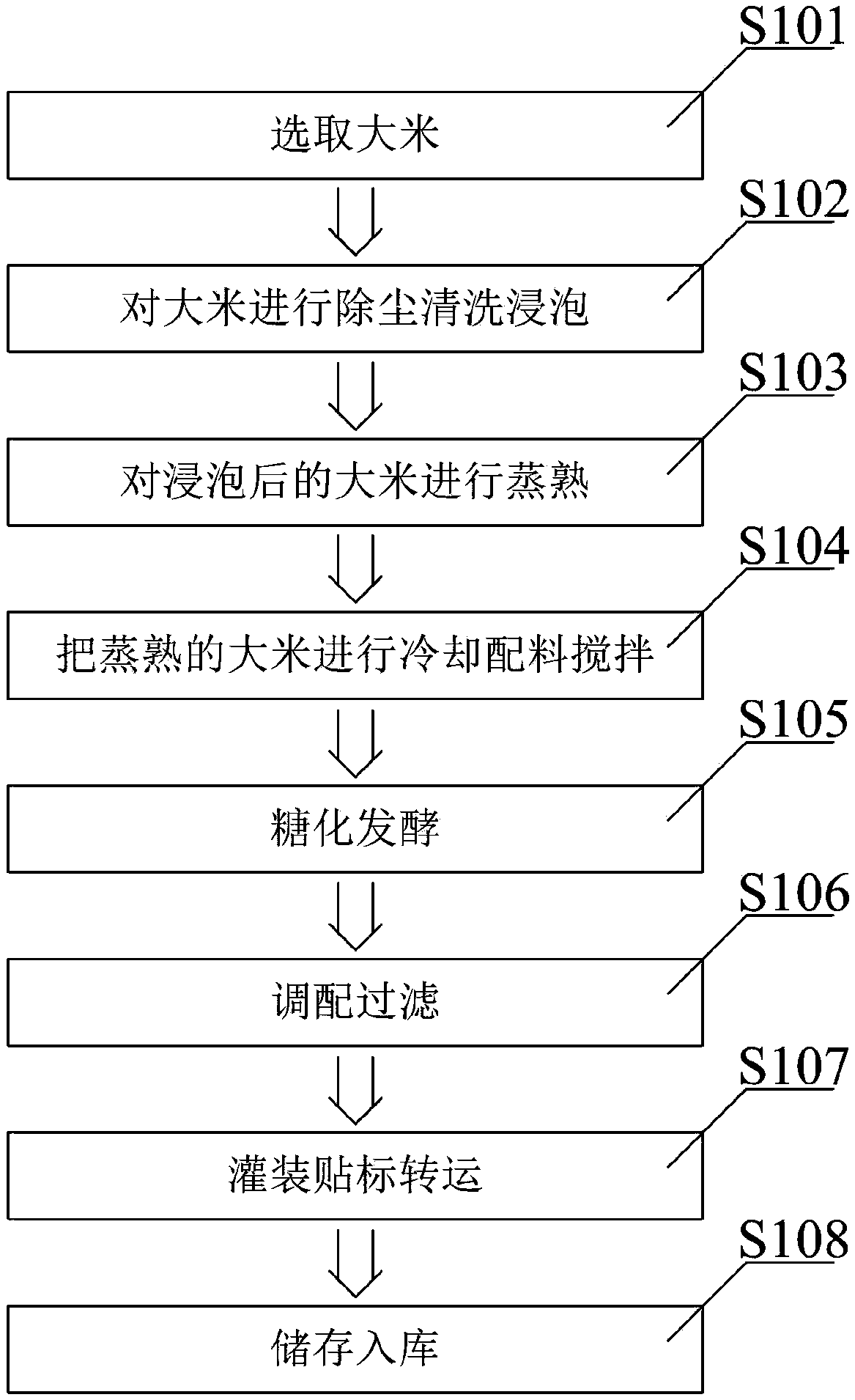

Energy-saving and environment-friendly rice wine brewing process

An energy-saving and environmentally friendly rice wine technology, applied in the field of wine manufacturing, can solve the problems of poor impurity removal effect of glutinous rice, inconvenient transportation of finished materials, inconvenient storage tank marking and other problems, and achieve good effect of impurity removal, convenient labeling and transshipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

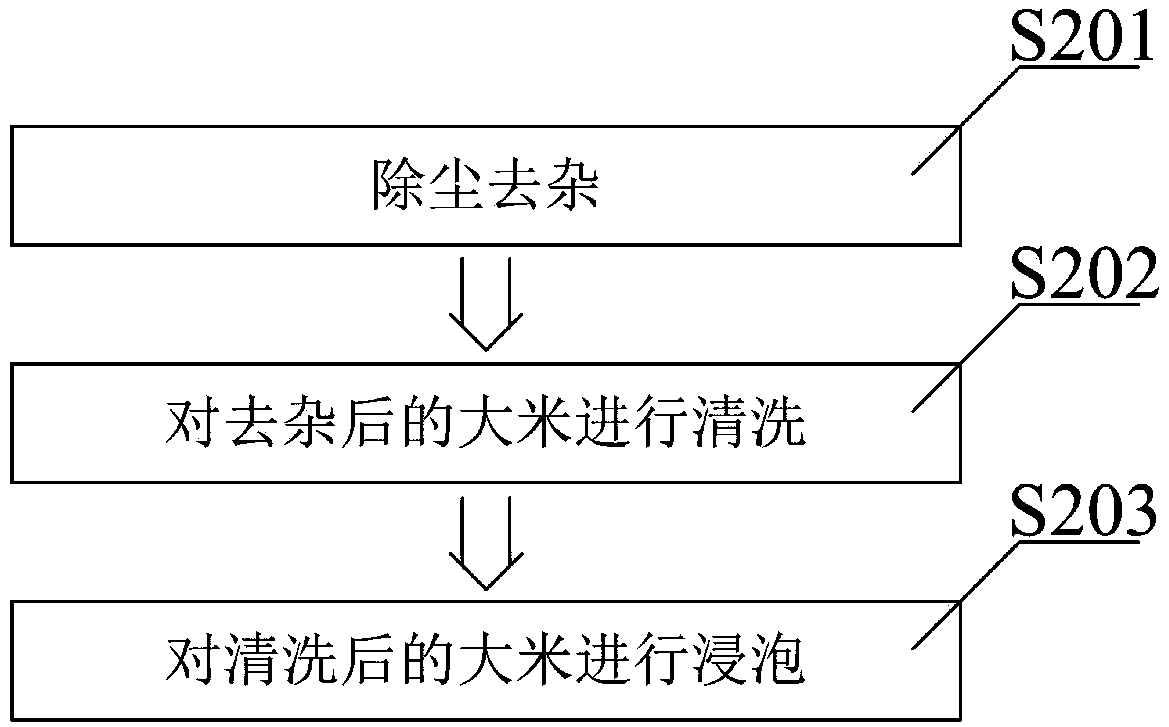

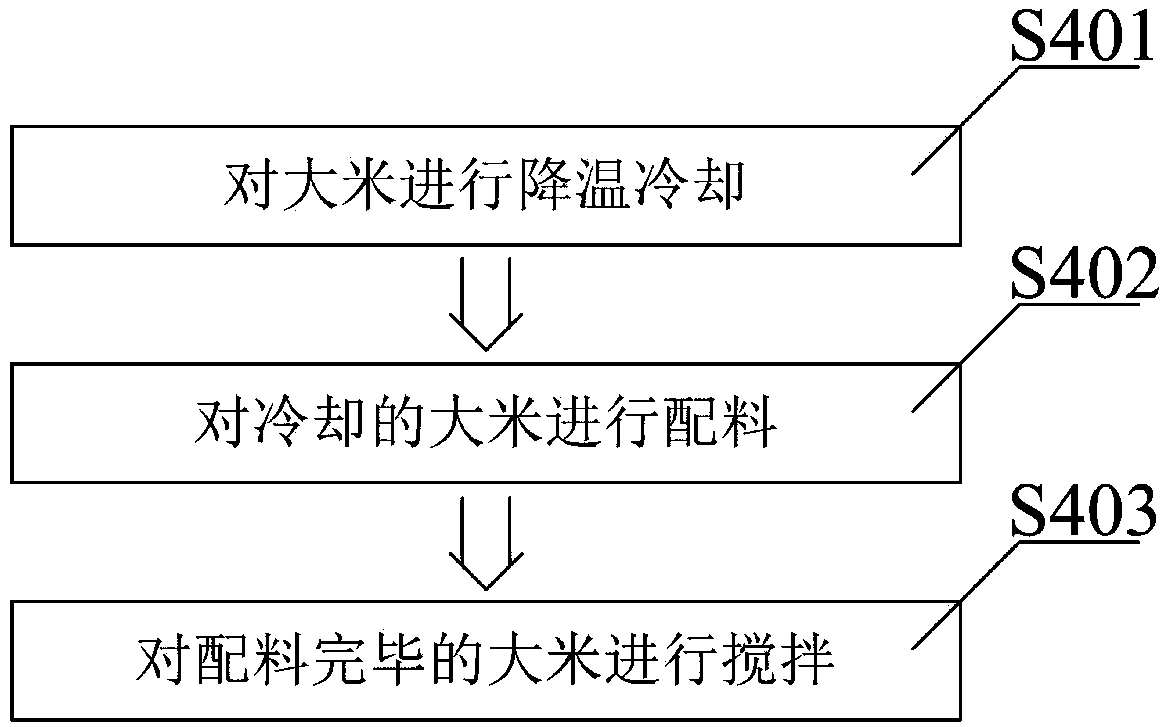

[0076] Example 1: Select plump glutinous rice grains, place the glutinous rice on an oscillator of model HY-4 to oscillate to screen out the dust and impurities on the glutinous rice, clean the glutinous rice after removing impurities, and place the oscillated glutinous rice in the Clean the inside of the basin and rinse the glutinous rice with pure water, pour the glutinous rice into the pure water of 25 to 25 to 30 percent by weight for soaking, and drain the water inside the glutinous rice after soaking , put the glutinous rice into the steamer, and add pure water 1.3 to 1.5 times the weight of the glutinous rice into the steamer, and steam the rice for 30 to 50 minutes, and cool the steamed glutinous rice to 20 degrees Celsius to 32 Celsius, mix the cooled steamed rice with koji wine to achieve ingredients, send the steamed rice mixed with koji wine into the mixing tank at the same time and mix it with a mixer of model LZ207 for a certain period of time. Saccharify at a te...

Embodiment 2

[0077] Example 2: Select plump glutinous rice grains, place the glutinous rice on an oscillator of model HY-4 to vibrate and sieve out the dust and debris on the glutinous rice, clean the glutinous rice after removing impurities, and place the vibrated glutinous rice in the Clean the inside of the basin and rinse the glutinous rice with pure water, pour the pure water with 26% to 29% by weight of the glutinous rice into the glutinous rice for soaking, and drain the water inside the glutinous rice after soaking Finally, put the glutinous rice into the steamer, and add purified water 1.4 to 1.5 times the weight of the glutinous rice into the steamer, and steam the rice for 35 to 50 minutes, and cool the steamed glutinous rice to 25 degrees Celsius To 32 degrees Celsius, mix the cooled steamed rice with koji wine to realize the ingredients, send the steamed rice mixed with koji wine into the mixing tank at the same time and mix it with a mixer of model LZ207 for ten to twenty minu...

Embodiment 4

[0078] Example 4: Select plump glutinous rice grains, place the glutinous rice on an oscillator of model HY-4 to vibrate and sieve out the dust and impurities on the glutinous rice, clean the glutinous rice after removing impurities, and place the vibrated glutinous rice in the Clean the inside of the basin and rinse the glutinous rice with pure water, pour the pure water with 28% to 29% by weight of the glutinous rice into the glutinous rice for soaking, and drain the water inside the glutinous rice after soaking Finally, put the glutinous rice into the steamer, and add purified water 1.5 times the weight of the glutinous rice into the steamer, and steam the rice for 40 to 50 minutes, and cool the steamed glutinous rice to 30 degrees Celsius to 32 degrees Celsius. Mix the cooled steamed rice with koji wine to achieve ingredients, send the steamed rice mixed with koji wine into the mixing tank at the same time and mix it with a mixer of model LZ207 for fifteen to twenty minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com