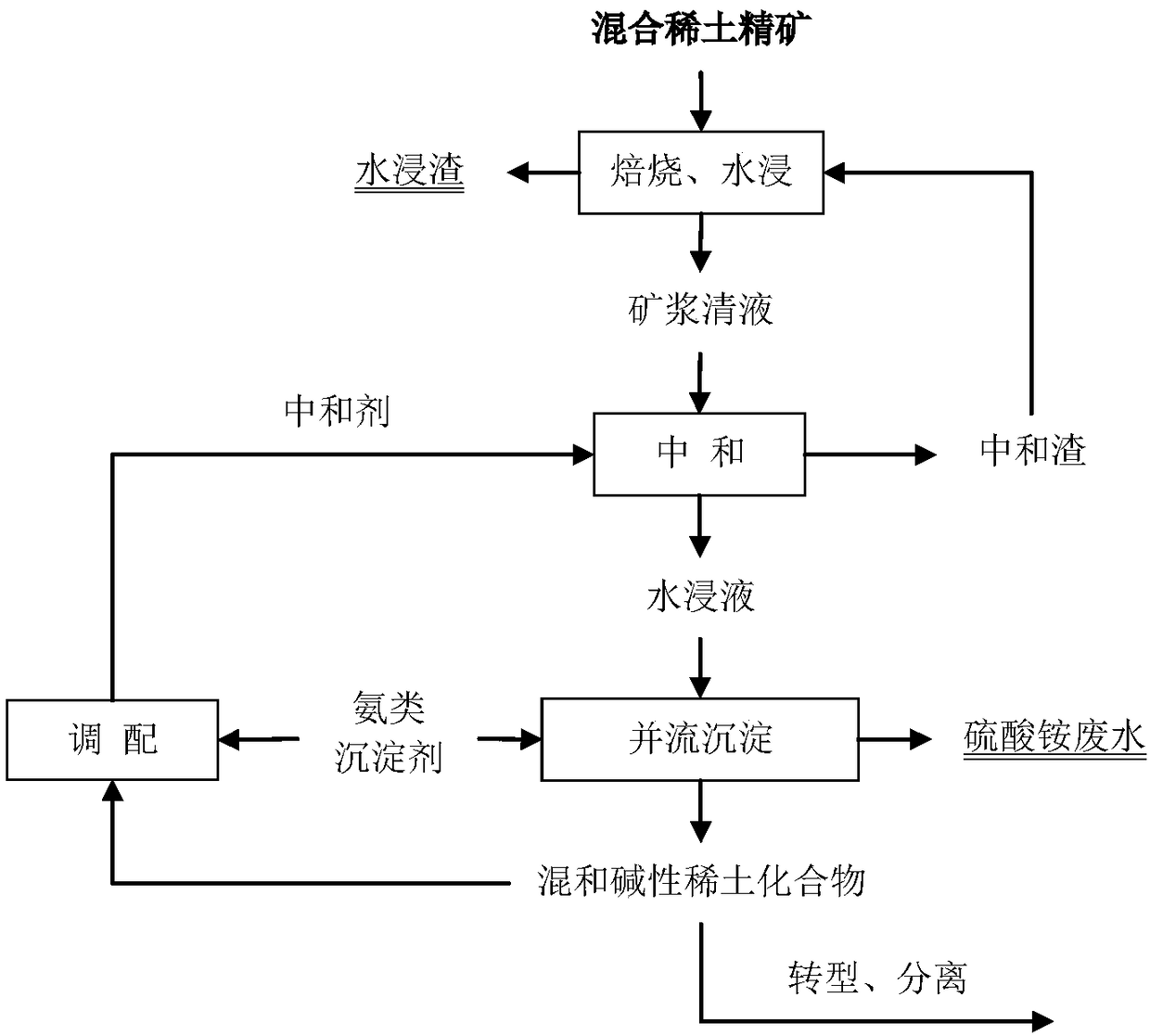

Method for preparing high-purity mixed rare earth chloride by sulfuric acid rare earth water leaching liquid neutralization, impurity removal and recycling

A technology of rare earth chloride and rare earth sulfate, applied in the direction of improving process efficiency, etc., can solve the problems of rare earth ammonium sulfate double salt precipitation, sulfate crystallization, etc., to reduce the difficulty of treatment, reduce contact, and prevent the production of rare earth ammonium sulfate double salt Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) The deployment of neutralizer: mixed rare earth carbonate: ammonia water=10:1 (molar ratio);

[0022] (2) Neutralization: the 30°C ore pulp clear liquid is neutralized with the prepared neutralizer to a pH value of 4.0, and the water immersion liquid and neutralized slag are obtained by separation. After the neutralized slag is mixed with water, it returns to the roasted ore leaching process;

[0023] (3) Precipitation transformation: water immersion liquid and ammonium bicarbonate precipitant co-flow and precipitate until the final pH value is 6.8, which is prepared as rare earth carbonate, and pure ammonium sulfate wastewater is obtained by separation, with a concentration of MgO of 0.21g / L and a concentration of CaO of 0.26g / L, ammonium sulfate by-product and reused water are obtained through concentrated crystallization;

[0024] (4) Recycling: Take mixed rare earth carbonate compounds according to demand, continue to be used to neutralize the clear liquid of o...

Embodiment 2

[0026] (1) The deployment of neutralizing agent: mixed alkaline rare earth compound: ammonium bicarbonate: ammoniacal liquor=1:5:10 (molar ratio of effective substance);

[0027] (2) Neutralization: The pulp clear liquid at 20°C is neutralized with the prepared neutralizer to a pH value of 4.2, and the water immersion liquid and neutralized slag are obtained by separation. After the neutralized slag is mixed with water, it returns to the roasted ore leaching process;

[0028] (3) Precipitation transformation: Ammonia water and ammonium bicarbonate are prepared as a mixed precipitant according to the molar ratio of 2:1, and the water immersion liquid and the mixed precipitant are precipitated in parallel until the final pH value is 6.2, and a mixed alkaline rare earth compound is prepared. Separate and obtain pure ammonium sulfate wastewater, its MgO concentration is 0.23g / L, CaO concentration is 0.32g / L, ammonium sulfate by-product and reuse water are obtained through concentr...

Embodiment 3

[0031] (1) Preparation of neutralizing agent: mixed rare earth carbonate: ammonium carbonate=99:1 (molar ratio).

[0032] (2) Neutralization: the 40°C ore pulp clear liquid is neutralized with the prepared neutralizer to a pH value of 3.8, and the water immersion liquid and neutralized slag are obtained by separation. After the neutralized slag is slurried with water, it returns to the roasted ore leaching process.

[0033] (3) Precipitation transformation: Ammonia water and ammonium bicarbonate are prepared as a mixed precipitant according to the molar ratio of 1:1, and the water immersion liquid and the mixed precipitant are precipitated in parallel until the final pH value is 6.5, and the mixed rare earth carbonate is prepared, separated Obtain pure ammonium sulfate waste water, its MgO concentration is 0.1g / L, CaO concentration is 0.2g / L, obtain ammonium sulfate by-product and reuse water through concentration and crystallization.

[0034] (4) Recycling: Collect mixed rar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com