Gradient Nb-Si based alloy film preparation method adopting high flux technology

A base alloy, high-throughput technology, applied in measurement devices, metal material coating processes, material analysis by optical means, etc., can solve the problems of large workload, large number of preparations, low efficiency, etc. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present application will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present application. Obviously, the described embodiments are merely examples and are not intended to limit the present application.

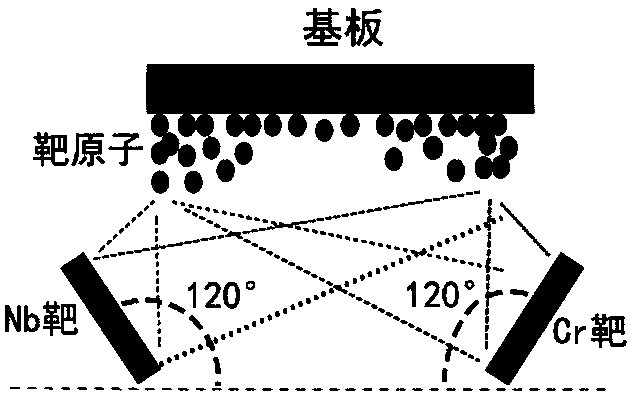

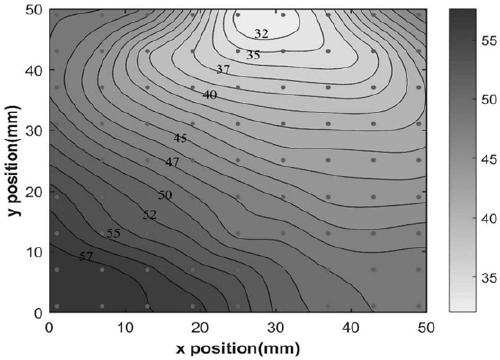

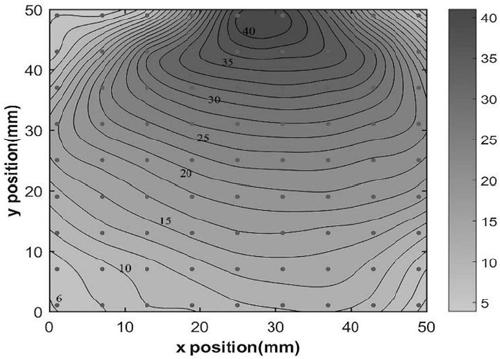

[0029] "Material high-throughput preparation" is the preparation of a large number of samples in a short time. The core idea is to change the sequential iterative or trial-and-error methods used in traditional materials research into parallel processing. The present invention provides a method for preparing a gradient Nb-Si-based alloy using high-throughput technology, which is described in detail below through specific examples.

[0030] A method for preparing gradient Nb-Si-based alloys using high-throughput technology includes the following steps:

[0031] The first step: the preparation and pretreatment of the substrate

[0032] (A) Using Nb, Si, Ti, Cr, Al as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com