Power plant waste heat and clean energy comprehensive utilization system

A technology of clean energy and power plant waste heat, applied in heating systems, space heating and ventilation, applications, etc., can solve the problem of low circulating water temperature, failure to meet the grade requirements of direct heating, and insufficient exhaust heat of low-pressure cylinders Use and other issues to achieve the effect of reducing the heat loss of the flue gas, reducing the heat loss of the cold source, and improving the thermal efficiency of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

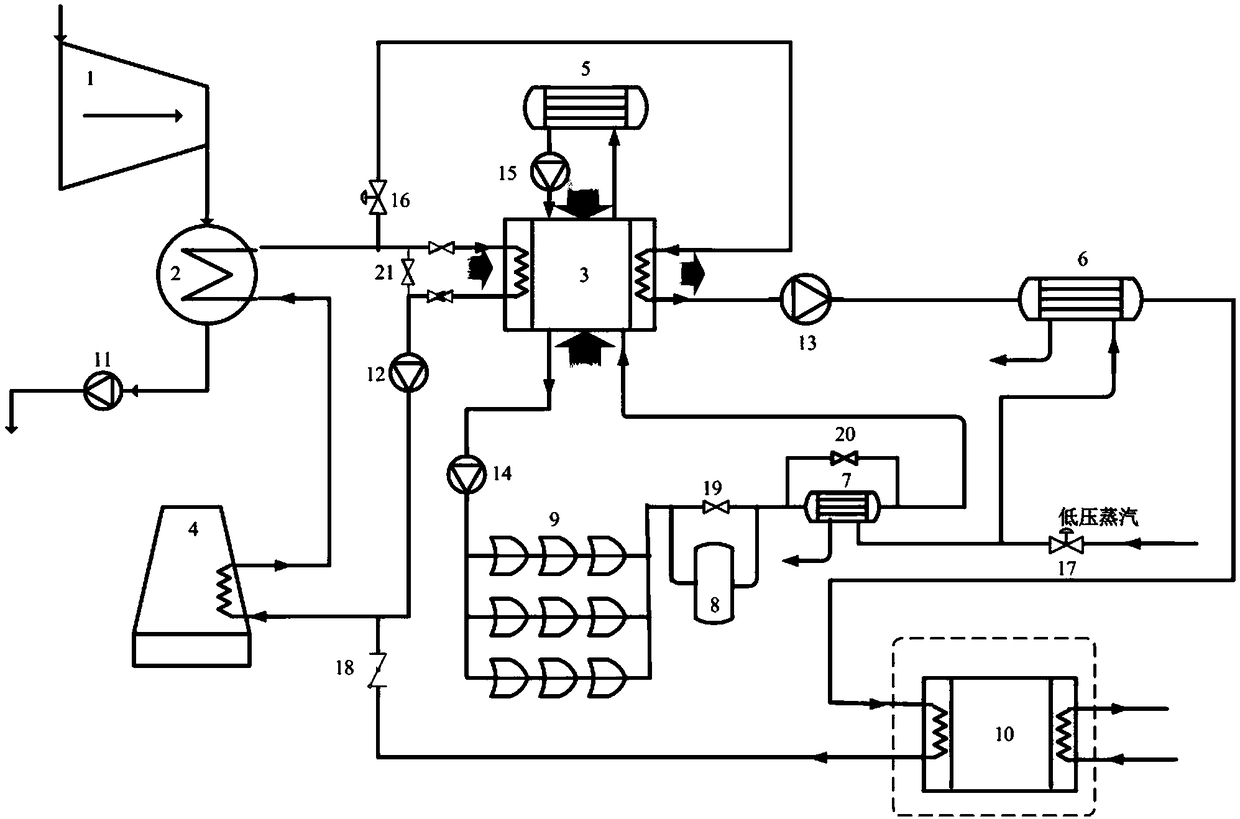

[0023] figure 1 It is a schematic diagram of the system of circulating water waste heat recovery, flue gas waste heat recovery and solar heat collection recovery of intermediate indirect air-cooled units. The indirect cooling surface condenser system is a Harmon system. see figure 1 , the circulating cooling water waste heat recovery, flue gas waste heat recovery and solar heat collection recovery system in this embodiment include a steam turbine unit 1, a condenser 2, an absorption heat pump 3, an indirect air cooling tower 4, and a flue gas-water heat exchanger 5. Steam-water heat exchanger 6, steam-heat transfer oil heat exchanger 7, heat accumulator 8, trough solar collector 9, secondary network heat exchange station 10, condensate pump 11, circulating water pump 12, hot water Circulation pump 13, heat conduction oil circulation pump ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap