Focusing device for monochromatic neutron

A focusing device and neutron technology, applied in the direction of material analysis using radiation, etc., can solve the problems of incomplete coincidence of neutron beams, increase of neutron beam spot area, influence of signal-to-noise ratio of spectrometer, etc., to improve neutron Intensity and utilization, beam spot uniformity, and the effect of increasing the reflective area of the wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

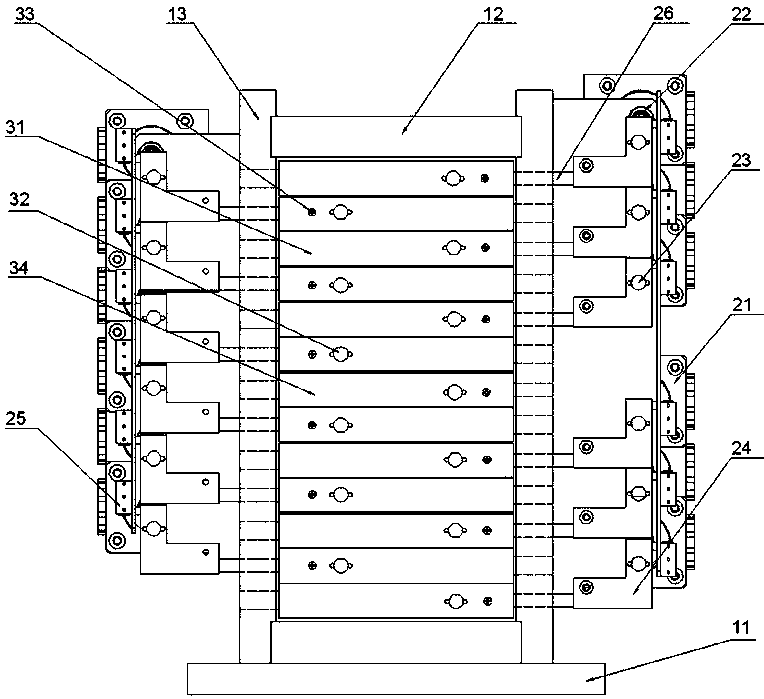

[0025] In this embodiment, m=6.

[0026] The working process of this embodiment is as follows:

[0027] Firstly, the stepper motor 21 drives the coupling 22 to move forward one end of the adjusting piece 24, the adjusting piece 24 rotates at a corresponding angle, the wafer fixing plate 31 rotates with the adjusting piece 24, adjusts the tilt angle of the wafer, and obtains the detector count corresponding to the tilt angle , the inclination angle is the best value when the neutron count is maximum. Then turn the adjusting screw 33 to push the upper layer of the wafer fixing plate 31, and the upper wafer fixing plate 31 forms a corresponding horizontal inclination angle to adjust the horizontal swing angle of the wafer. The corresponding horizontal swing angle of the detector maximum count is the optimum value.

[0028] There are 12 stepping motors (21) in this embodiment, which are respectively installed on two side plates, and the shaft coupling (22) is installed on the rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com