A method for evaluating the loss amount and loss rate of lost components in a gas-solid catalyst

A technology of loss rate and evaluation method, applied in measurement devices, analytical materials, instruments, etc., can solve problems such as DPF blockage and SCR poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1: Measuring the volatilization amount and volatilization rate of element vanadium in a vanadium-based SCR sample, comprising the following steps,

[0068] (1) SCR carrier measurement: remove the metal shell and cushion of the SCR sample to obtain the SCR carrier, blow and clean the surface of the SCR carrier with compressed air, weigh it with an electronic balance, and the result is accurate to 0.1g, and measure the SCR carrier with a vernier caliper The diameter and height, the result is accurate to 0.1mm, calculate its volume.

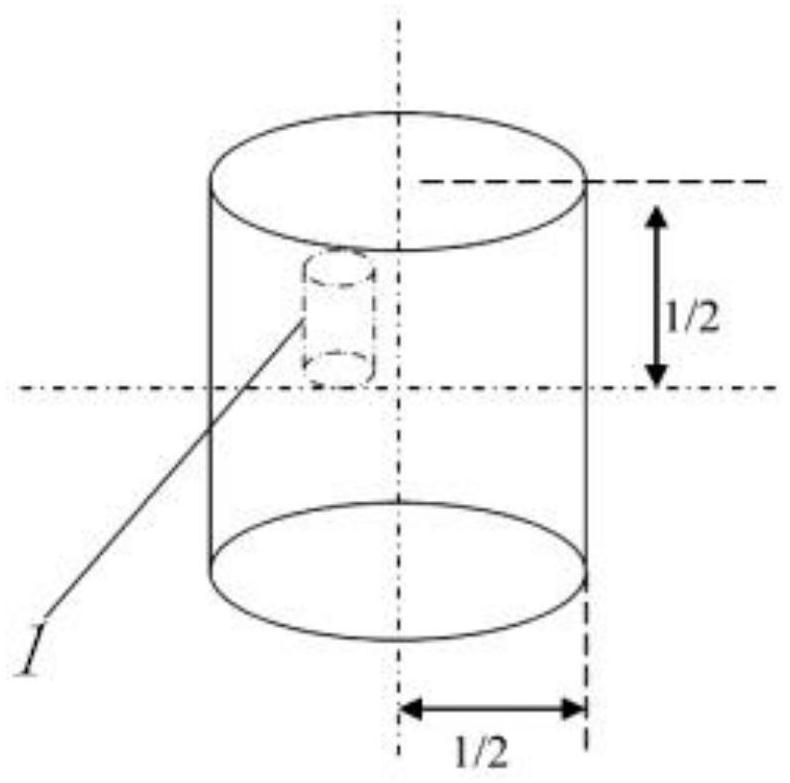

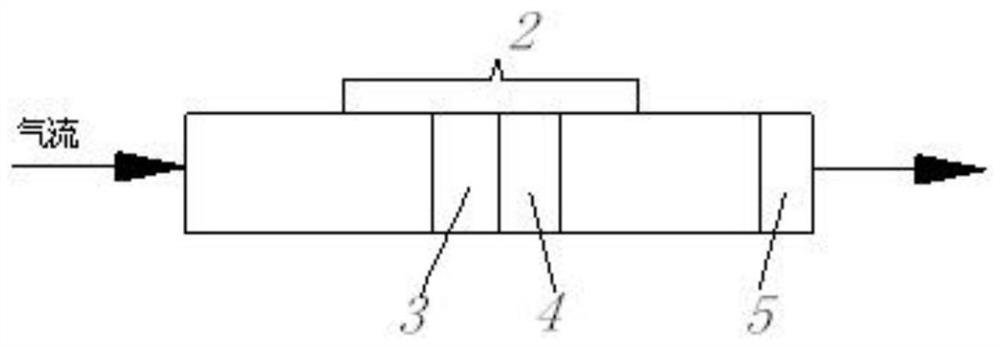

[0069] (2) SCR carrier sampling: see the sampling diagram figure 1 , cut the SCR carrier from the vertical 1 / 2 and the horizontal 1 / 2 respectively to obtain four parts: the upper left part, the upper right part, the lower left part and the lower right part, and any part of it is taken. The sampling part 1 is to sample from the center of the carrier. The sampling specification is Φ20mm×25mm. After purging and cleaning the surface o...

Embodiment 2

[0109] Example 2: Measuring a coating coated with V 2 o 5 The volatilization amount and volatilization rate of element vanadium in the DPF sample

[0110] Change the measurement sample to one coated with V 2 o 5 DPF sample, others are the same as embodiment 1.

Embodiment 3

[0111] Example 3: Measuring the volatilization amount and volatilization rate of elemental tungsten in the vanadium-based SCR sample

[0112] The measured volatile element was replaced by tungsten, the mass number of the selected isotope was 182W, the internal standard element used was replaced by 185Re, and the others were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com