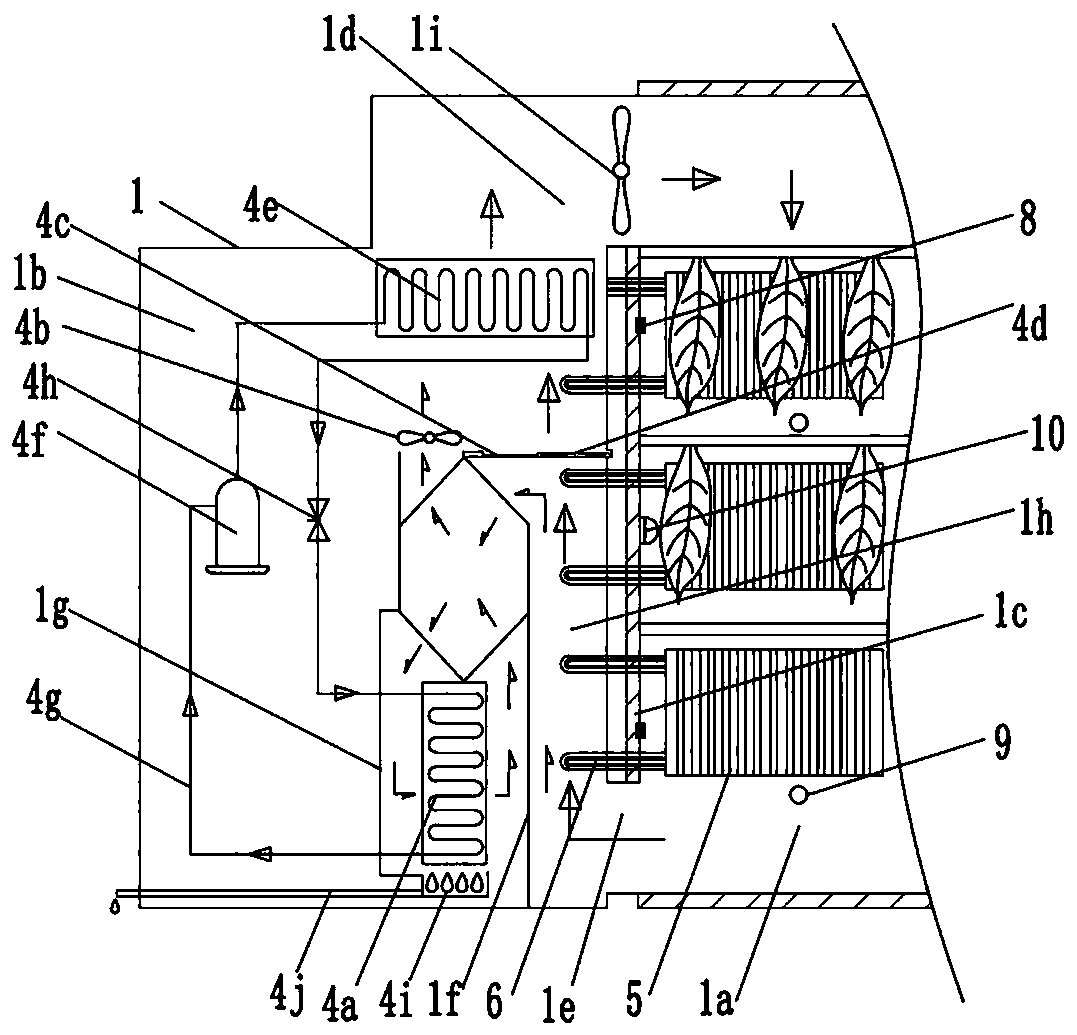

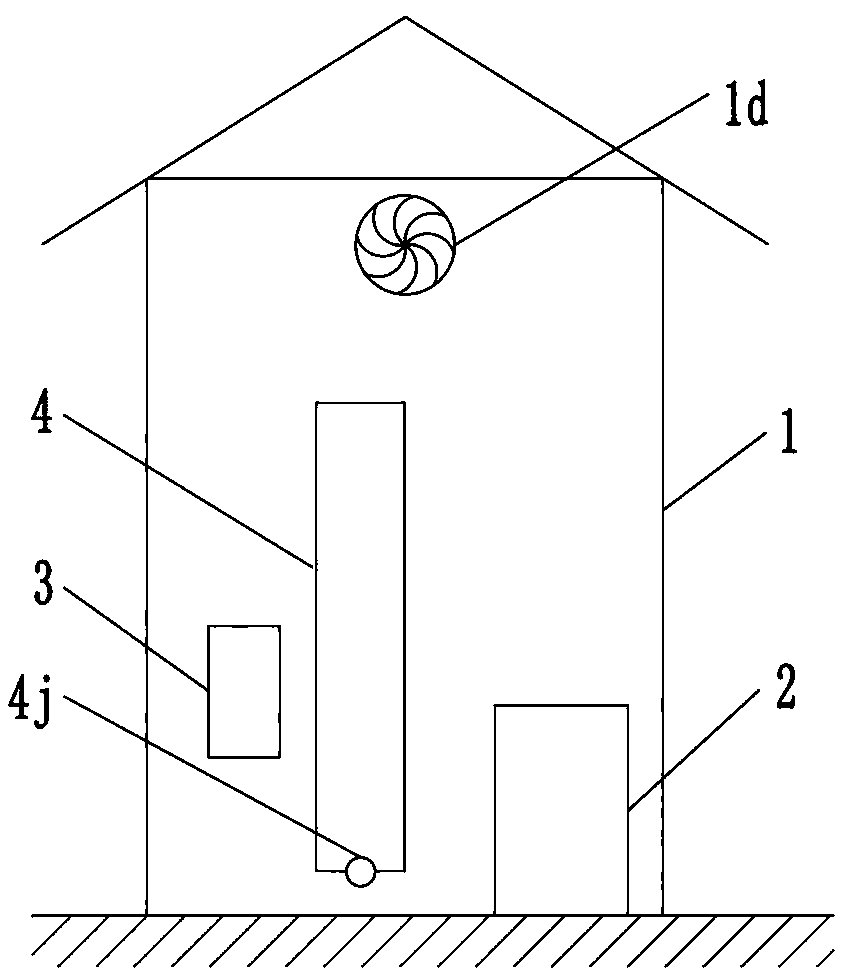

A frequency conversion type flue-cured tobacco heat pump double-power curing barn and a curing and blending process thereof

A variable-frequency, dual-power technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems that the temperature adjustment is not fine and stable, the output power can only be controlled in sections, and the heating efficiency is low, so as to ensure the coordination of color setting, The effect of preventing tobacco leaves from being roasted under high temperature conditions and reducing the rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

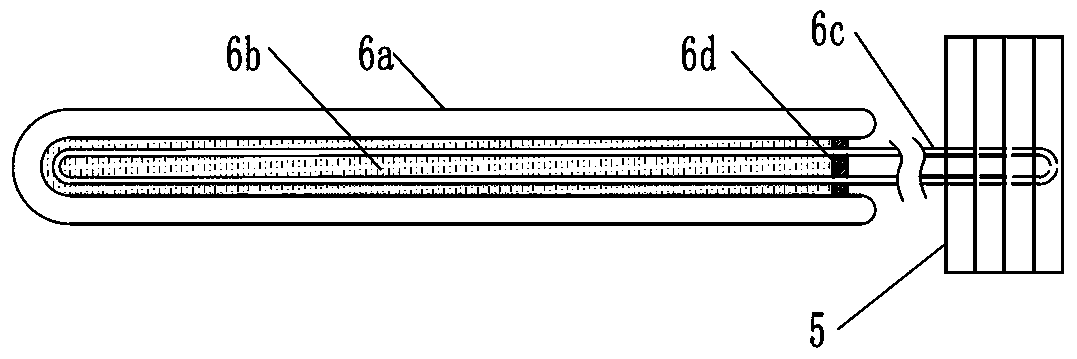

Method used

Image

Examples

Embodiment 1

[0075] 1A. After the tobacco leaves are loaded into the barn, after ignition, the dry bulb temperature is raised from room temperature to 37.0°C at a synchronous heating rate of 2.0°C / h, and the wet bulb temperature is 36.0°C. The humid air discharged from the flue-cured tobacco room 1a in 1h is pre-cooled and discharged to the heat pump evaporator 4a, and the humid air condenses on the surface of the heat pump evaporator 4a to form droplets to achieve dehumidification, so that the humid air can be dehumidified before entering Tobacco flue-curing room 1a, until the tobacco leaves in the high-temperature layer turn yellow by 6-8 cm;

[0076] 1B. With a synchronous temperature rise rate of 1.0°C / h, the dry bulb temperature is raised to 38.0°C and the wet bulb temperature is 37.0°C, and then the heat exchange device 7 is operated to absorb the humid air discharged from the flue-cured tobacco room 1a in the air duct for 1h, The moist air is pre-cooled and discharged to the heat pu...

Embodiment 2

[0090] (1) Yellowing period

[0091] 1A. After the tobacco leaves are loaded into the barn, after ignition, the dry bulb temperature is raised from room temperature to 38.0°C at a synchronous heating rate of 2.0°C / h, and the wet bulb temperature is 37.0°C. The humid air discharged from the flue-cured tobacco room 1a in 1h is pre-cooled and discharged to the heat pump evaporator 4a, and the humid air condenses on the surface of the heat pump evaporator 4a to form droplets to achieve dehumidification, so that the humid air can be dehumidified before entering Tobacco flue-curing room 1a, until the tobacco leaves in the high-temperature layer turn yellow by 6-8 cm;

[0092] 1B. With a synchronous heating rate of 1.0°C / h, the dry bulb temperature is raised to 40.0°C, and the wet bulb temperature is 38.0°C, and then the heat exchange device 7 is operated to absorb the humid air discharged from the flue-cured tobacco room 1a in the air duct for 1h, The moist air is pre-cooled and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com