Hollow fiber membrane oxygenator externally arranged on heat exchange layer

A technology of heat exchange layer and oxygenator, which is applied in the field of medical devices, can solve the problems of reduced blood flow uniformity, reduced thrombus formation, and reduced gas exchange efficiency, so as to reduce the probability of thrombus formation, small body temperature fluctuations, and temperature loss low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 A hollow fiber membrane oxygenator with an external heat exchange layer

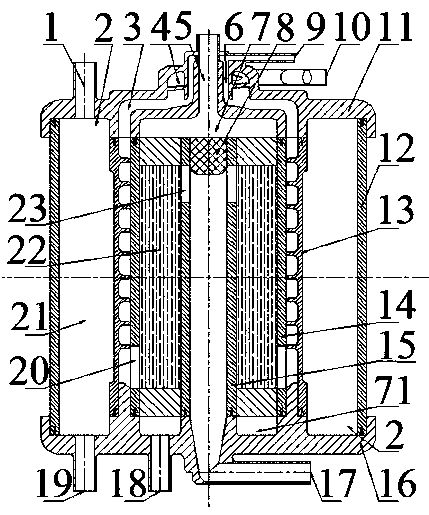

[0045] A hollow fiber membrane oxygenator with an external heat exchange layer, such as figure 1 As shown, the overall shape is cylindrical; the oxygenator includes a shell and an upper end cover 11 and a lower end cover 16 detachably installed on the shell; the shell includes an oxygenator shell 12, a hot water unit Shell 13, oxygenation unit shell 14 and core tube 15; the oxygenator shell 12 and the hot water unit inner shell 13 form the cavity of the hot water unit 21, and the hot water unit inner shell 13 and the oxygenation unit shell 14 form the blood heat exchange Cavity, the shell 14 of the oxygenation unit and the core tube 15 constitute the cavity of the oxygenation unit 22 (that is, the oxygen-permeable hollow fiber membrane).

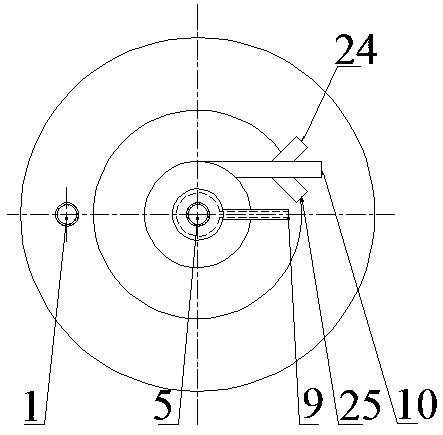

[0046] Such as figure 2 As shown, the upper end cover 11 is respectively provided with a water outlet pipe 1, an air inlet pipe 5, an exhaust pipe ...

Embodiment 2

[0062] Example 2 A hollow fiber membrane oxygenator with an external heat exchange layer

[0063] In order to further improve the comprehensive use effect of the oxygenator, the hollow fiber membrane oxygenator with an external heat exchange layer in this embodiment has the following improvements on the basis of Example 1:

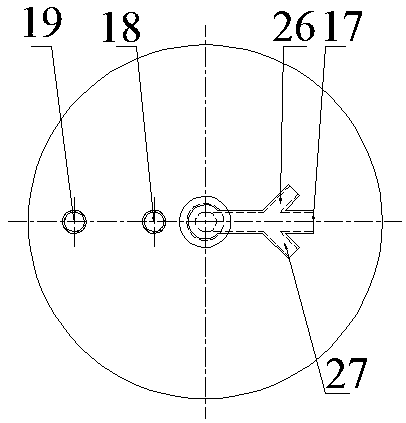

[0064] Such as figure 1 , Figure 5 and Image 6 As shown, in the hollow fiber membrane oxygenator with an external heat exchange layer in this embodiment, the four first circumferential openings 20 at the lower end of the oxygenation unit housing 14 and the four second circumferential openings at the upper end of the core tube 15 The outer edges of 23 are rounded. The rounded corner design can fully reduce the shearing effect between the blood and the edge of the hole when the blood flows through the hole, and reduce the degree of blood damage. A seal 8 with rounded corners is provided on the upper part of the inner cavity of the core tube 15 . When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com