Process for refining coal

A coal and process technology, applied in the field of coal refining process, can solve the problems of high processing cost, low removal efficiency, complicated process, etc., and achieve the effects of improving service performance, high removal efficiency and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

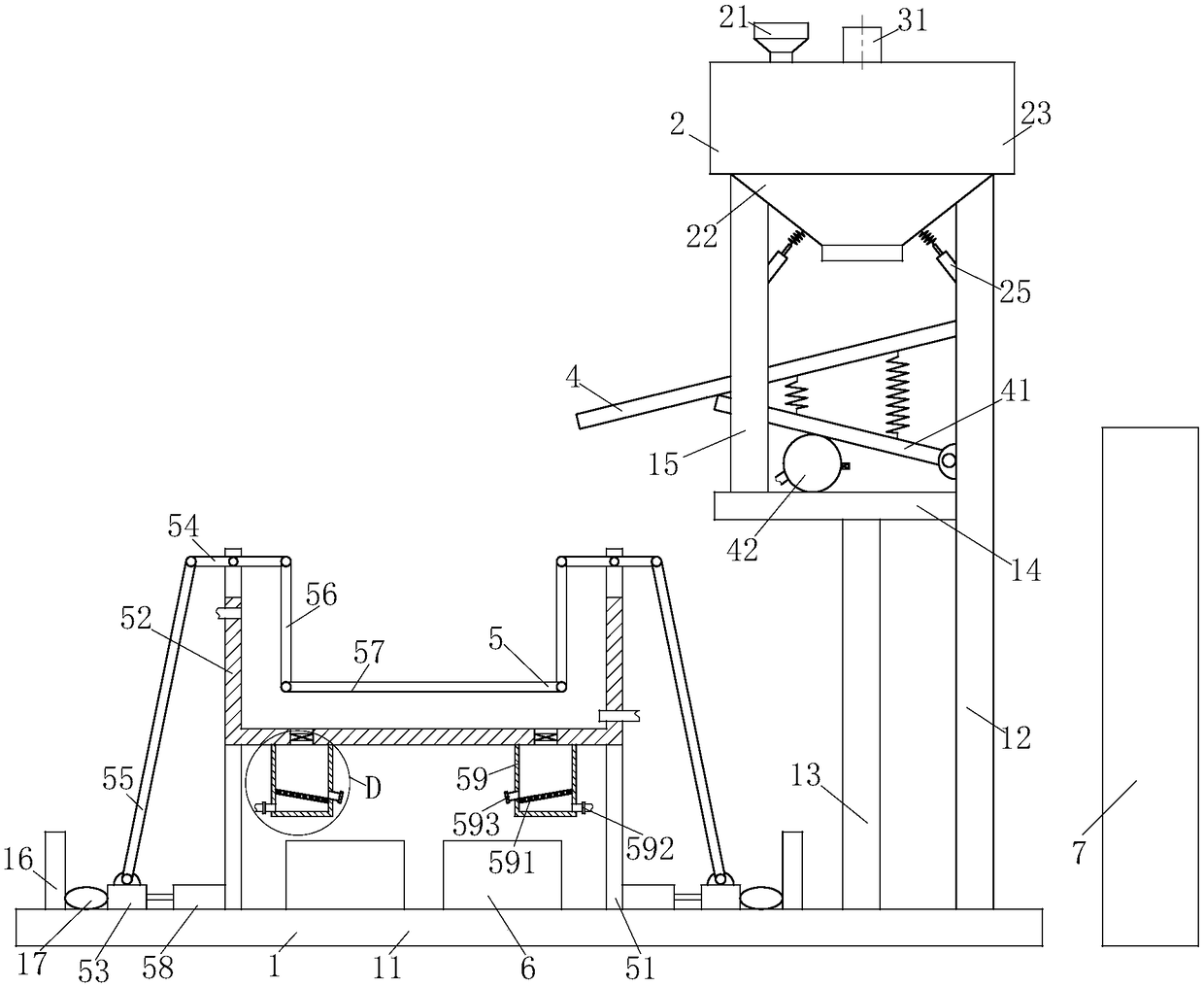

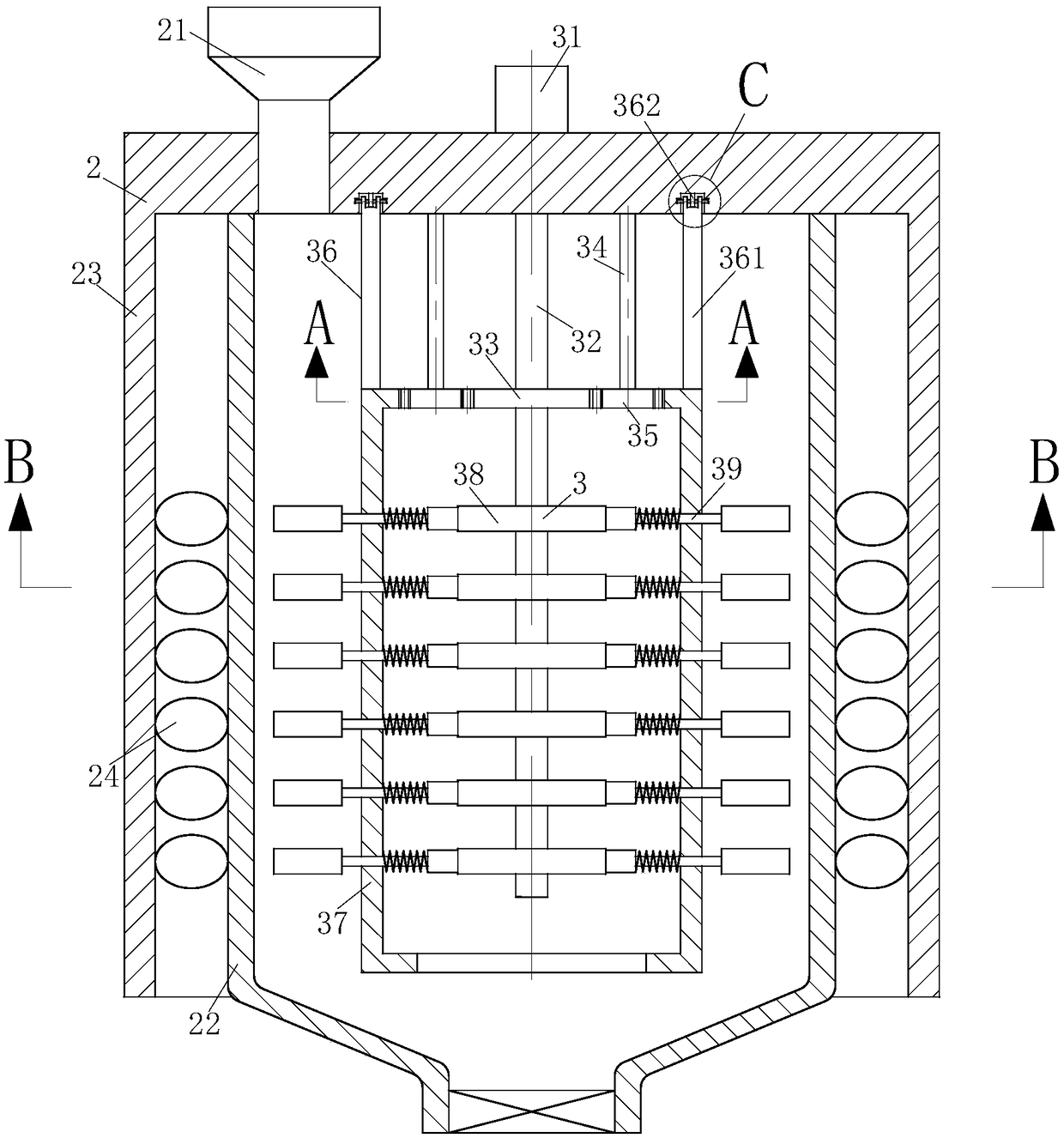

[0028] use Figure 1-Figure 7 The coal refining process according to one embodiment of the present invention will be described below.

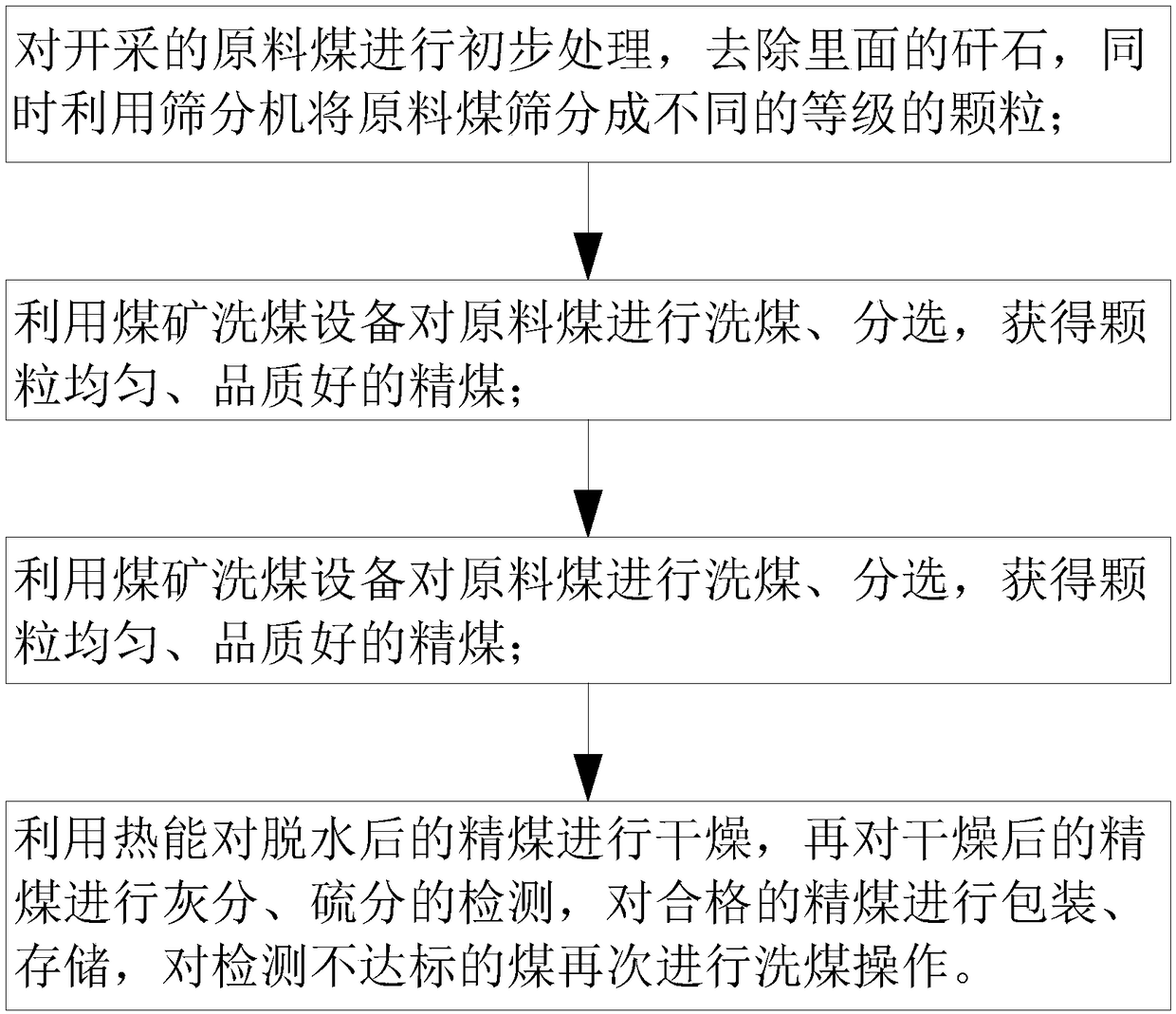

[0029] Such as Figure 1 to Figure 3 Shown, a kind of coal mine coal washing equipment of the present invention, this technique comprises the steps:

[0030] Step 1: Preliminary treatment of the mined raw coal to remove the gangue inside, and at the same time use a screening machine to screen the raw coal into particles of different grades;

[0031] Step 2: After screening in step 1, use coal mine coal washing equipment to wash and separate the raw coal to obtain clean coal with uniform particles and good quality;

[0032] Step 3: After obtaining the cleaned coal in step 2, use a dehydration device to dehydrate the obtained clean coal to ensure the quality of the clean coal;

[0033] Step 4: After dehydration in step 3, use thermal energy to dry the dehydrated clean coal, then test the ash and sulfur content of the dried clean coal, pack an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com