Preparation method for transition metal doped antimony telluride alloy target material

A technology of antimony telluride alloy and transition metal, which is applied in the field of preparation of antimony telluride alloy target, which can solve the problems of difficult control of target material composition, uneven distribution of elements, and easy deformation of target material, so as to achieve good product controllability , uniform element distribution and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of Sb 2 Te 3 target

[0026] 1) Add about 54g Sb 2 Te 3 The powder is added to a graphite mold with an inner diameter of 50mm coated with boron nitride;

[0027] 2) Put the powder and mold in step 1) into the hot-press furnace, seal the furnace body, vacuumize, and keep the low pressure in the furnace below 0.01Pa;

[0028] 3) At room temperature, apply a pressure of about 28 MPa to the mold, and completely release the pressure after holding the pressure for 5 minutes;

[0029] 4) Raise the temperature in the furnace to 200°C, and under the condition of 200°C, apply a pressure of 40MPa to the mold and hold the pressure for 5 minutes before completely releasing the pressure;

[0030] 5) Raise the temperature in the furnace to 400°C at a rate of 10°C / min, and at 400°C, apply a pressure of 40MPa to the mold and keep the pressure for 5 minutes;

[0031] 6) After the pressure holding process in step 5), cool naturally to room temperature, and release the pr...

Embodiment 2

[0034] Preparation Y 0.25 Sb 1.75 Te 3 target

[0035] 1) Add about 54g Y 0.25 Sb 1.75 Te 3 The powder is added to a graphite mold with an inner diameter of 50mm coated with boron nitride;

[0036] 2) Put the powder and mold in step 1) into the hot-press furnace, seal the furnace body, vacuumize, and keep the low pressure in the furnace below 0.01Pa;

[0037] 3) At room temperature, apply a pressure of about 28 MPa to the mold, and completely release the pressure after holding the pressure for 5 minutes;

[0038] 4) Raise the temperature in the furnace to 200°C, and under the condition of 200°C, apply a pressure of 40MPa to the mold and hold the pressure for 5 minutes before completely releasing the pressure;

[0039] 5) Raise the temperature in the furnace to 400°C at a rate of 10°C / min, and at 400°C, apply a pressure of 40MPa to the mold and keep the pressure for 5 minutes;

[0040] 6) After the pressure holding process in step 5), cool naturally to room temperature,...

Embodiment 3

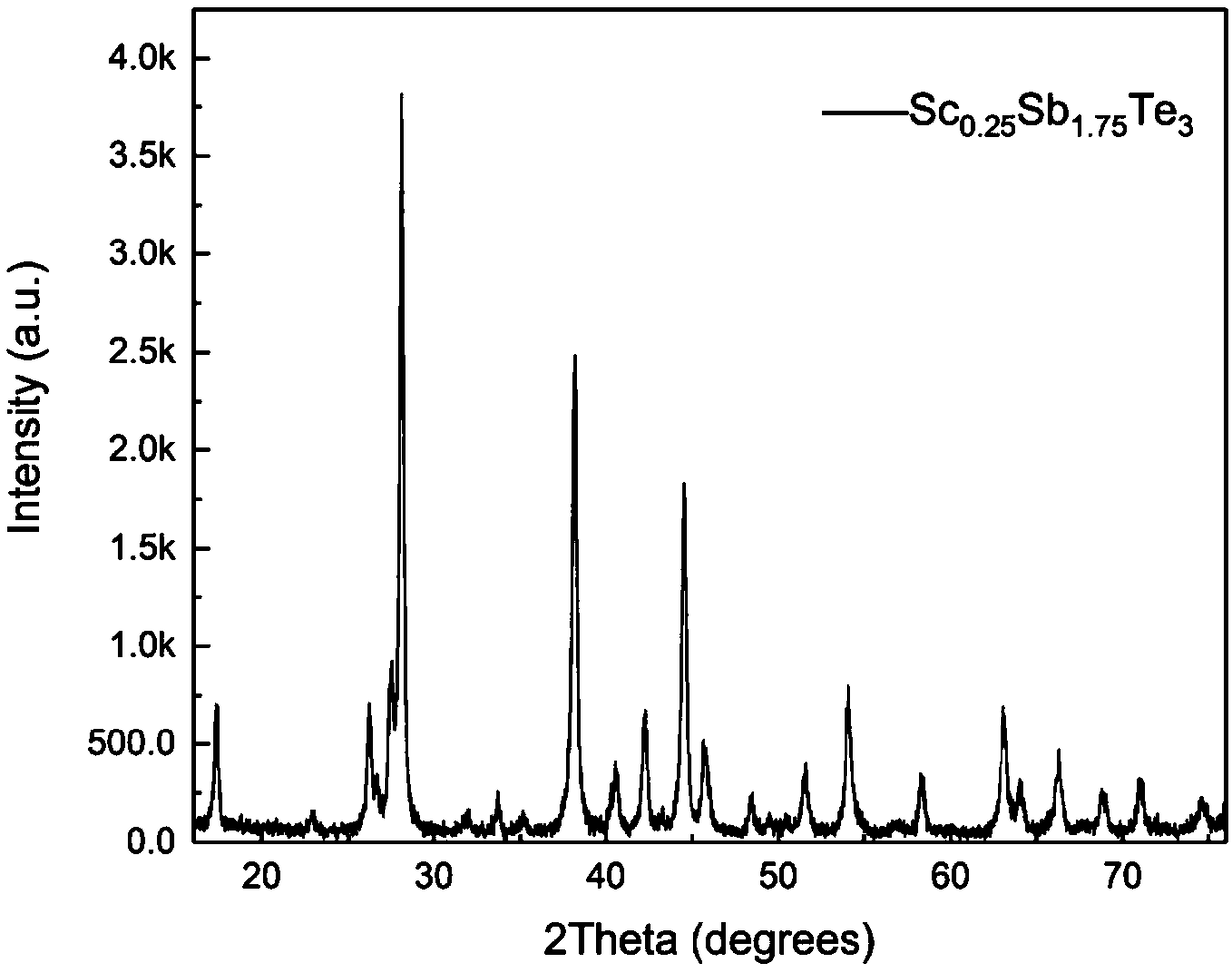

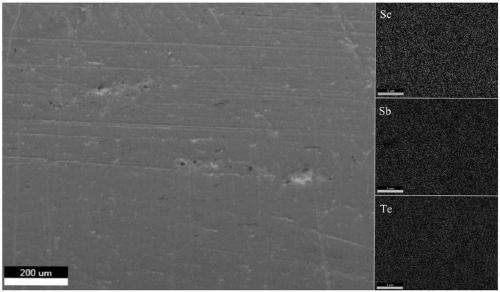

[0043] Preparation of Sc 0.25 Sb 1.75 Te 3 target

[0044] 1) Add about 54g Sc 0.25 Sb 1.75 Te 3 The powder is added to a graphite mold with an inner diameter of 50mm coated with boron nitride;

[0045] 2) Put the powder and mold in step 1) into the hot-press furnace, seal the furnace body, vacuumize, and keep the low pressure in the furnace below 0.01Pa;

[0046] 3) At room temperature, apply a pressure of about 28 MPa to the mold, and completely release the pressure after holding the pressure for 5 minutes;

[0047] 4) Raise the temperature in the furnace to 200°C, and under the condition of 200°C, apply a pressure of 40MPa to the mold and hold the pressure for 5 minutes before completely releasing the pressure;

[0048] 5) Raise the temperature in the furnace to 400°C at a rate of 10°C / min, and at 400°C, apply a pressure of 40MPa to the mold and keep the pressure for 5 minutes;

[0049] 6) After the pressure holding process in step 5), cool naturally to room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com