System and method for accumulating nitrite nitrogen in partial nitrification process

A short-range nitrification and nitrous nitrogen technology, applied in the field of ammonia nitrogen-containing sewage treatment, can solve the problems of poor operation stability and inconvenient system operation, and achieve the effects of small footprint, short process flow and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

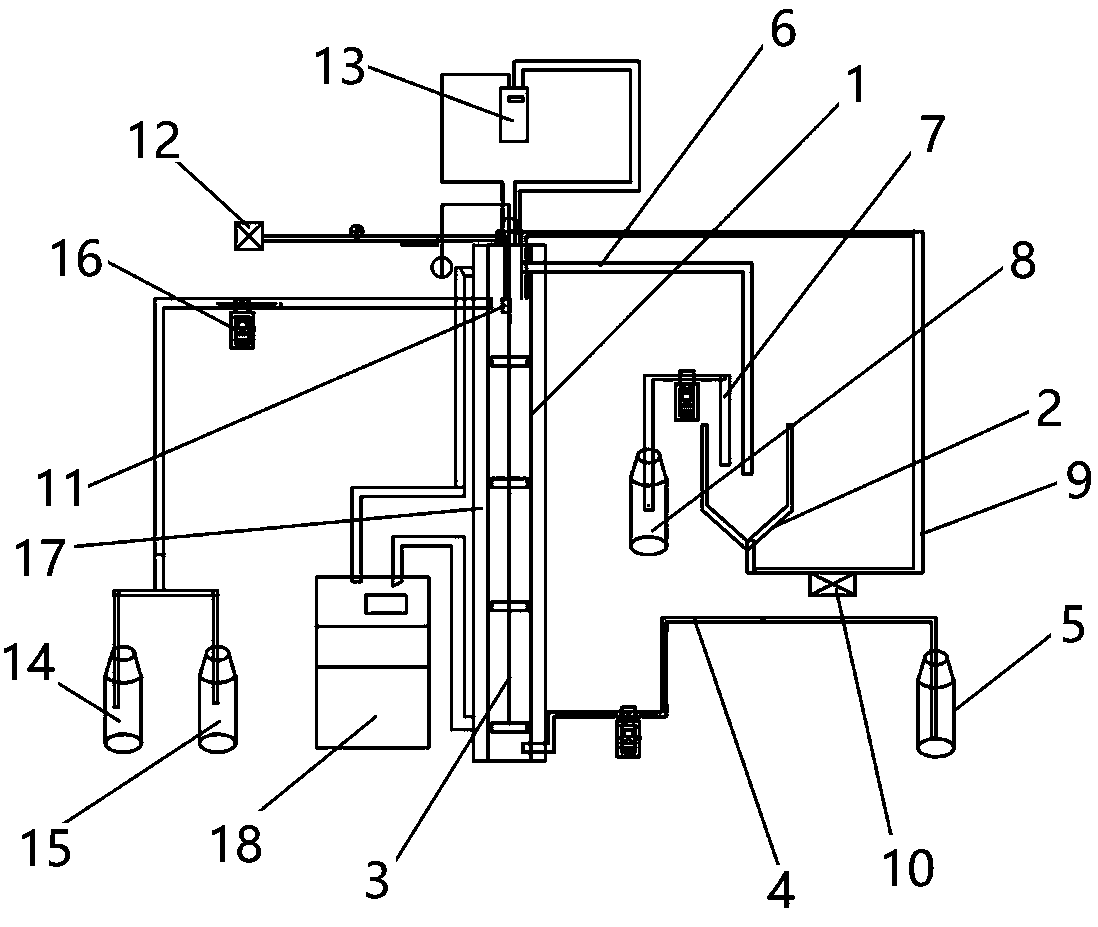

[0036] like figure 1As shown, the system structure of the present invention includes a stirred upflow reaction 1, a vertical flow sedimentation tank 2, a water quality monitoring device, an aeration device and an acid-base adjustment device. Stirred upflow reactor 1 is a cylindrical reactor with an aspect ratio of 10-15, and a stirring device 3 is provided in the cylindrical reactor, and the stirring device 3 includes a stirring rod arranged along the axis of the stirred upflow reactor 1. Stirring blades distributed on the stirring rod and a speed controller connected with the stirring rod. During operation, the stirring device can be controlled at an appropriate stirring speed by the speed controller as required.

[0037] The bottom of the stirred upflow reactor 1 is connected to the water inlet tank 5 through the water inlet pipe 4, and the top of the stirred upflow reactor 1 is connected to the vertical flow sedimentation tank 2 through the reactor outlet pipe 6, and the ve...

Embodiment 2

[0042] The method for accumulating nitrous nitrogen in the short-range nitrification process of the present invention comprises the following steps:

[0043] a. Set up the above-mentioned system for accumulating nitrous nitrogen, wherein the height of the stirred upflow reactor is 115 cm, and the inner diameter is 9.5 cm.

[0044] b. Add digested sludge from the aeration tank of Baoding Sewage Treatment Plant to the stirred upflow reactor. After adding, the MLSS is 4189 mg / L, and the surface aeration head, pH probe, dissolved oxygen probe and oxidation The reduction potential probe is submerged 17cm below the liquid surface.

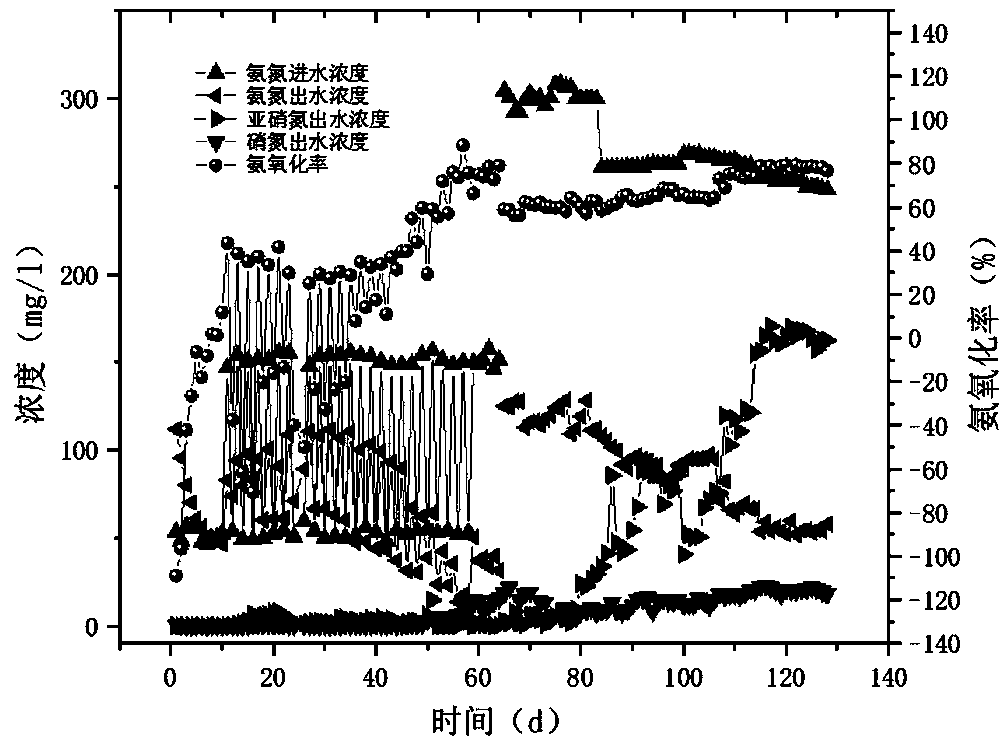

[0045] c. Acclimatization stage: the DO at the dissolved oxygen probe is controlled to be 0.6~0.7mg / L, the pH is 7.5~8.5, the ORP is 10~200mV, the temperature is 25~35°C, and the concentration of ammonia nitrogen is set to 150mg / L and ammonia nitrogen concentration of 50mg / L wastewater are alternately fed into the water for domestication until the ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com