PETG (Polyethylene Terephthalate Glycol) modified copolyester

A copolyester and modification technology, which is applied in the field of preparation of modified copolyester, can solve the problems that are not conducive to large-scale promotion, low strength of heat shrinkable film, and affect product quality, so as to prevent depolymerization, improve stability, The effect of increasing the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

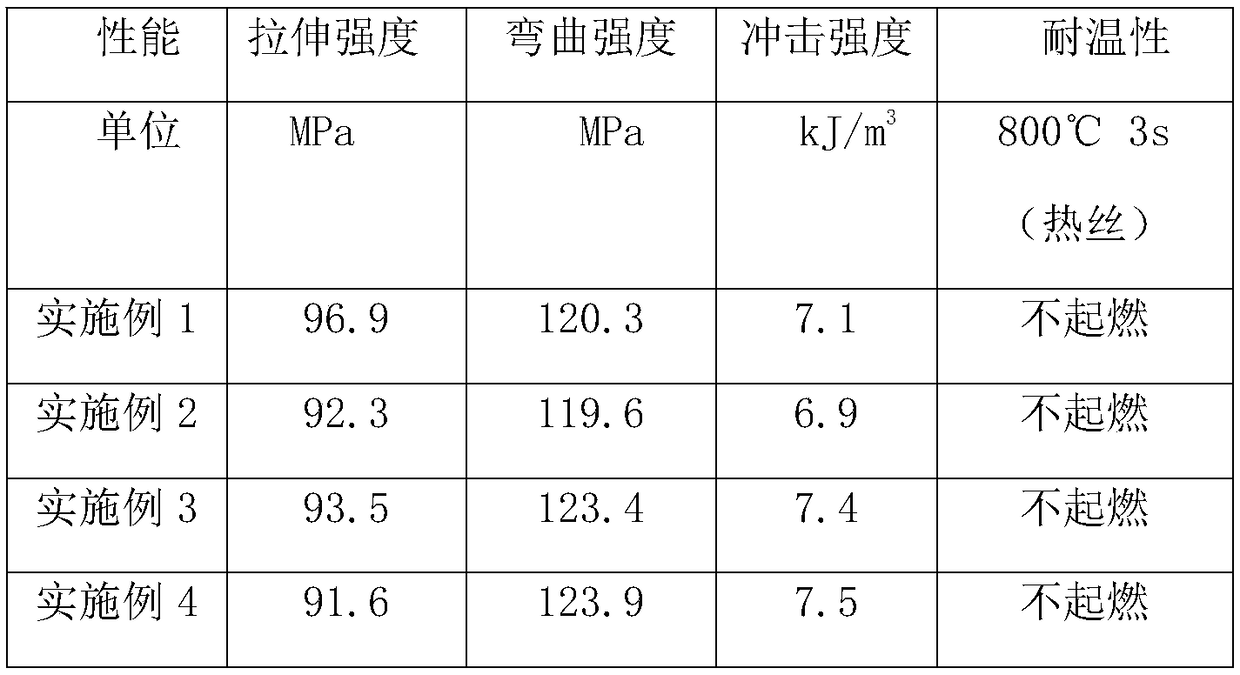

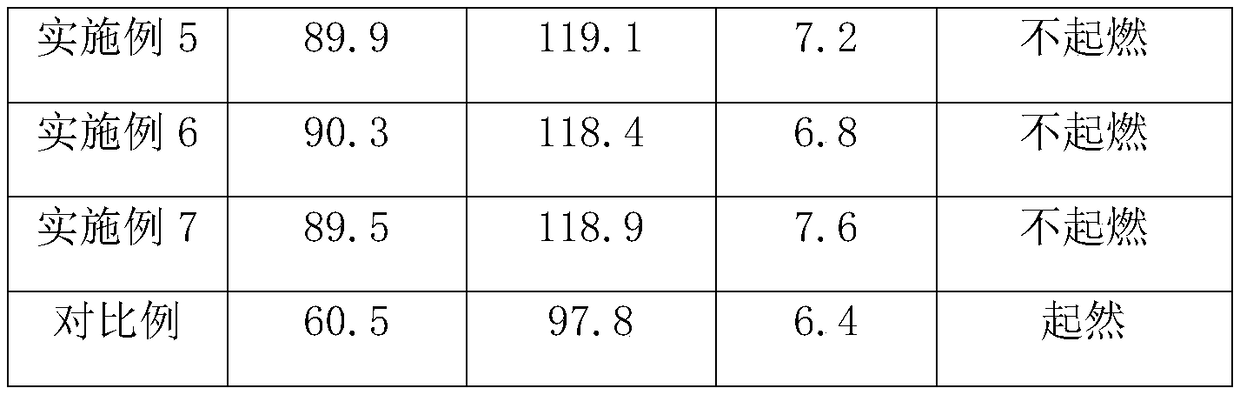

Examples

Embodiment 1

[0022] A PETG modified copolyester, comprising by weight components: 65 parts of terephthalic acid, 15 parts of ethylene glycol, 18 parts of neopentyl glycol, 10 parts of aminopropylmethyldiethoxysilane, phosphoric acid 5 parts of trialkyl ester, 20 parts of trimellitic anhydride, 12 parts of 1,1-cyclopropyldicarboxylic acid, 8 parts of decabromodiphenylethane, 10 parts of 2-acetoxy-4-methoxybenzophenone, 5 parts of 3,5-dichlorobenzenesulfonamide, 6 parts of manganese dioxide, 1 part of stabilizer, 2 parts of antioxidant, 2 parts of compatibilizer.

[0023] The preparation method of above-mentioned a kind of PETG modified copolyester comprises the following steps:

[0024] (1) Mix and stir terephthalic acid, ethylene glycol, neopentyl glycol, and manganese dioxide with a magnetic stirring bar, and stir for 15 minutes at a stirring speed of 1000 r / min under a pressure of 0.12 MPa to obtain a mixed solution, and then stir in a microwave Under heating conditions, trialkyl phosph...

Embodiment 2

[0028] A PETG modified copolyester, comprising by weight components: 70 parts of terephthalic acid, 18 parts of ethylene glycol, 21 parts of neopentyl glycol, 13 parts of aminopropylmethyldiethoxysilane, phosphoric acid 6 parts of trialkyl ester, 23 parts of trimellitic anhydride, 15 parts of 1,1-cyclopropyldicarboxylic acid, 10 parts of decabromodiphenylethane, 13 parts of 2-acetoxy-4-methoxybenzophenone, 9 parts of 3,5-dichlorobenzenesulfonamide, 8 parts of manganese dioxide, 1 part of stabilizer, 2 parts of antioxidant, and 2 parts of compatibilizer.

[0029] The preparation method of above-mentioned a kind of PETG modified copolyester comprises the following steps:

[0030](1) Mix and stir terephthalic acid, ethylene glycol, neopentyl glycol, and manganese dioxide with a magnetic stirring bar, and stir for 20 minutes at a stirring speed of 1000 r / min under a pressure of 0.13 MPa to obtain a mixed solution, and then stir in a microwave Under heating conditions, add trialky...

Embodiment 3

[0034] A PETG modified copolyester, comprising by weight components: 85 parts of terephthalic acid, 20 parts of ethylene glycol, 25 parts of neopentyl glycol, 15 parts of aminopropylmethyldiethoxysilane, phosphoric acid 7 parts of trialkyl esters, 25 parts of trimellitic anhydride, 18 parts of 1,1-cyclopropyldicarboxylic acid, 13 parts of decabromodiphenylethane, 15 parts of 2-acetoxy-4-methoxybenzophenone, 12 parts of 3,5-dichlorobenzenesulfonamide, 10 parts of manganese dioxide, 2 parts of stabilizer, 3 parts of antioxidant, and 3 parts of compatibilizer.

[0035] The preparation method of above-mentioned a kind of PETG modified copolyester comprises the following steps:

[0036] (1) Mix and stir terephthalic acid, ethylene glycol, neopentyl glycol, and manganese dioxide with a magnetic stirring rod, and stir for 25 minutes at a stirring speed of 1000 r / min under a pressure of 0.15 MPa to obtain a mixed solution, and then stir in a microwave Under heating conditions, add tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com