Environment-friendly coalescent compound

The technology of a coalescing agent and composition is applied in the field of coalescing agents to achieve the effects of superior color development, good compatibility, and improvement of paint film hardness and wet friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0022] Form the coalescent composition of the present invention according to the weight percent listed in table 1, then allocate in the commercially available water-based latex paint according to the formula ratio listed in table 2, allocate and stir according to the normal use method of each water-based latex paint .

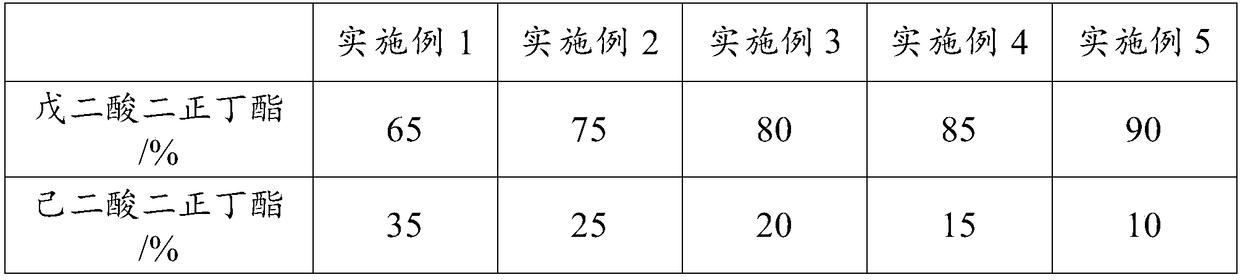

[0023] Table 1: Component content of coalescence agent in embodiment 1~5

[0024]

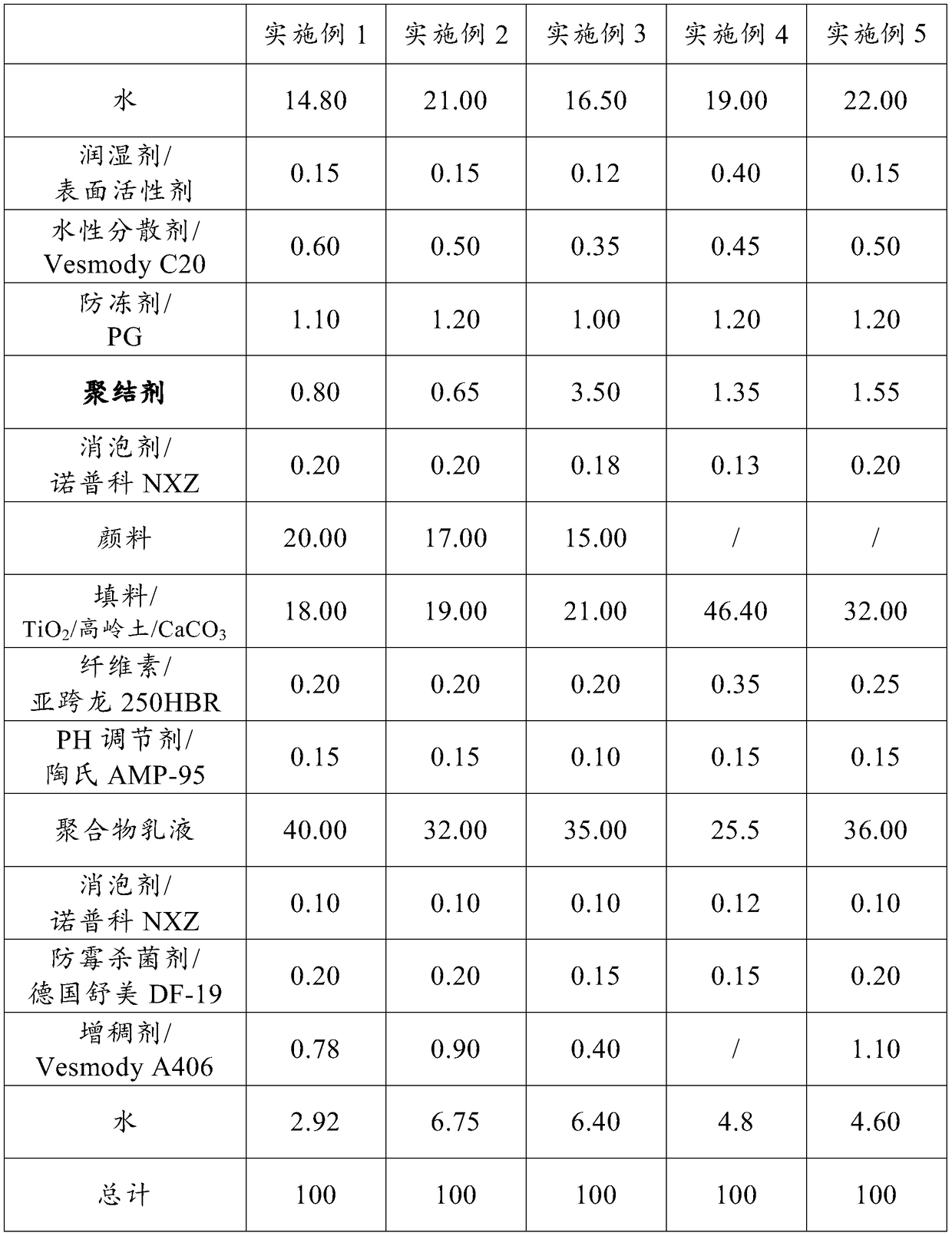

[0025] Wherein, the polymer emulsion in embodiment 1 and 2 is polyacrylate (PA) emulsion, the polymer emulsion in embodiment 3 is polyvinyl acetate (VA) emulsion, and the polymer emulsion in embodiment 4 is self-crosslinking waterproof benzene Acrylic emulsion (SA) emulsion, the polymer emulsion in embodiment 5 is vinegar acrylic emulsion.

[0026] Table 2: Proportion of the environment-friendly coalescent composition of Examples 1-5

[0027] (the data unit of each component in the table is parts by mass)

[0028]

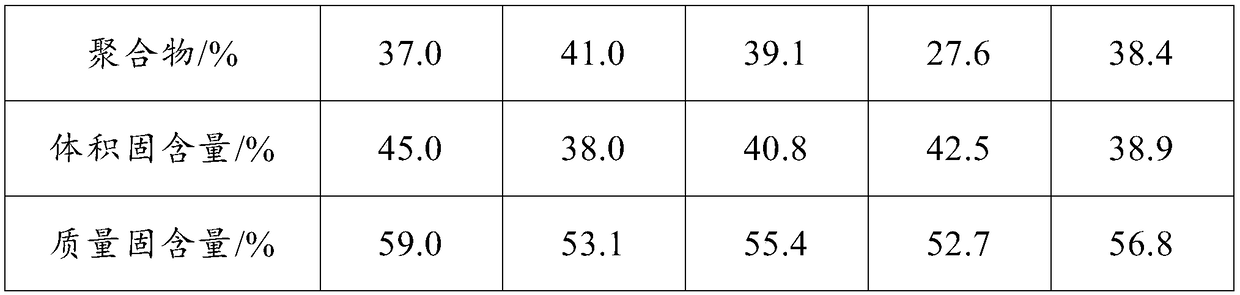

[0029]

[0030] After the preparation of the paint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com