Hydrogen energy clean fuels as well as preparation equipment and pre-mixing treatment process of hydrogen energy clean fuels

A technology of clean fuel and processing technology, applied in the direction of fuel, gas fuel, petroleum industry, etc., can solve the problems of complex preparation and increase production cost, and achieve the effect of high reactivity, cost saving, and increase of unsaturation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

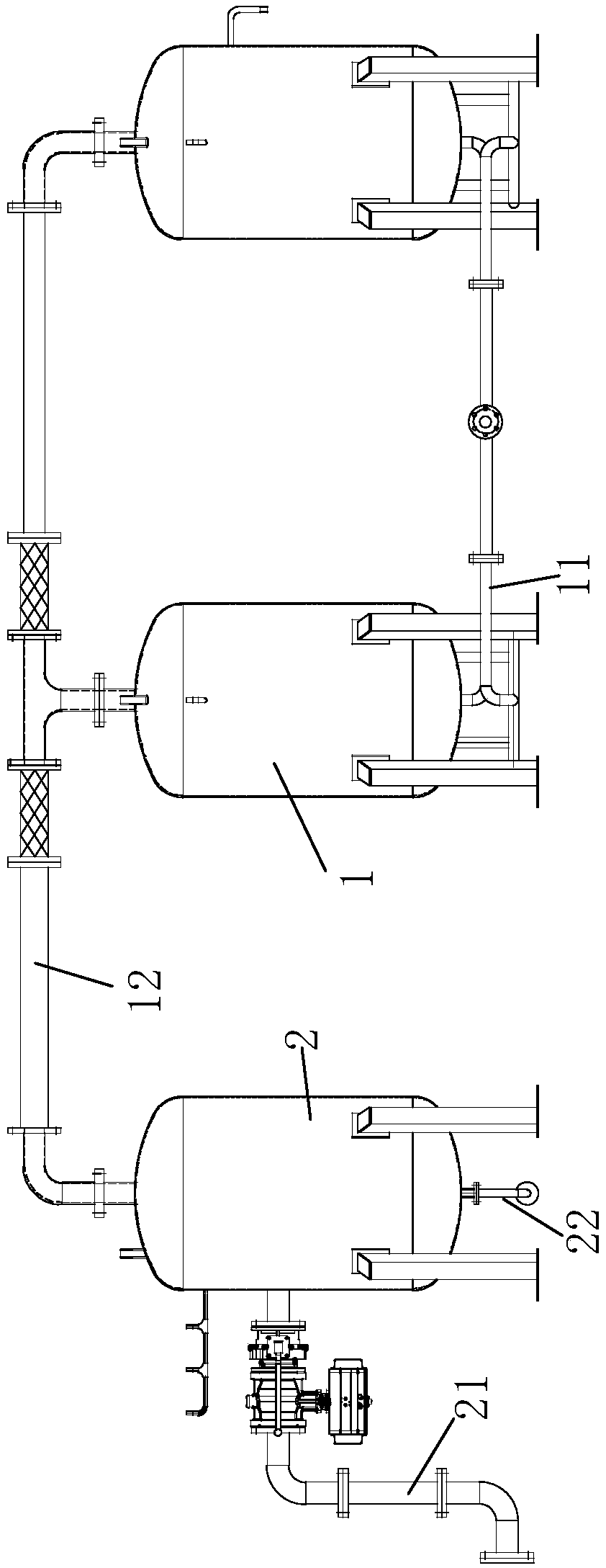

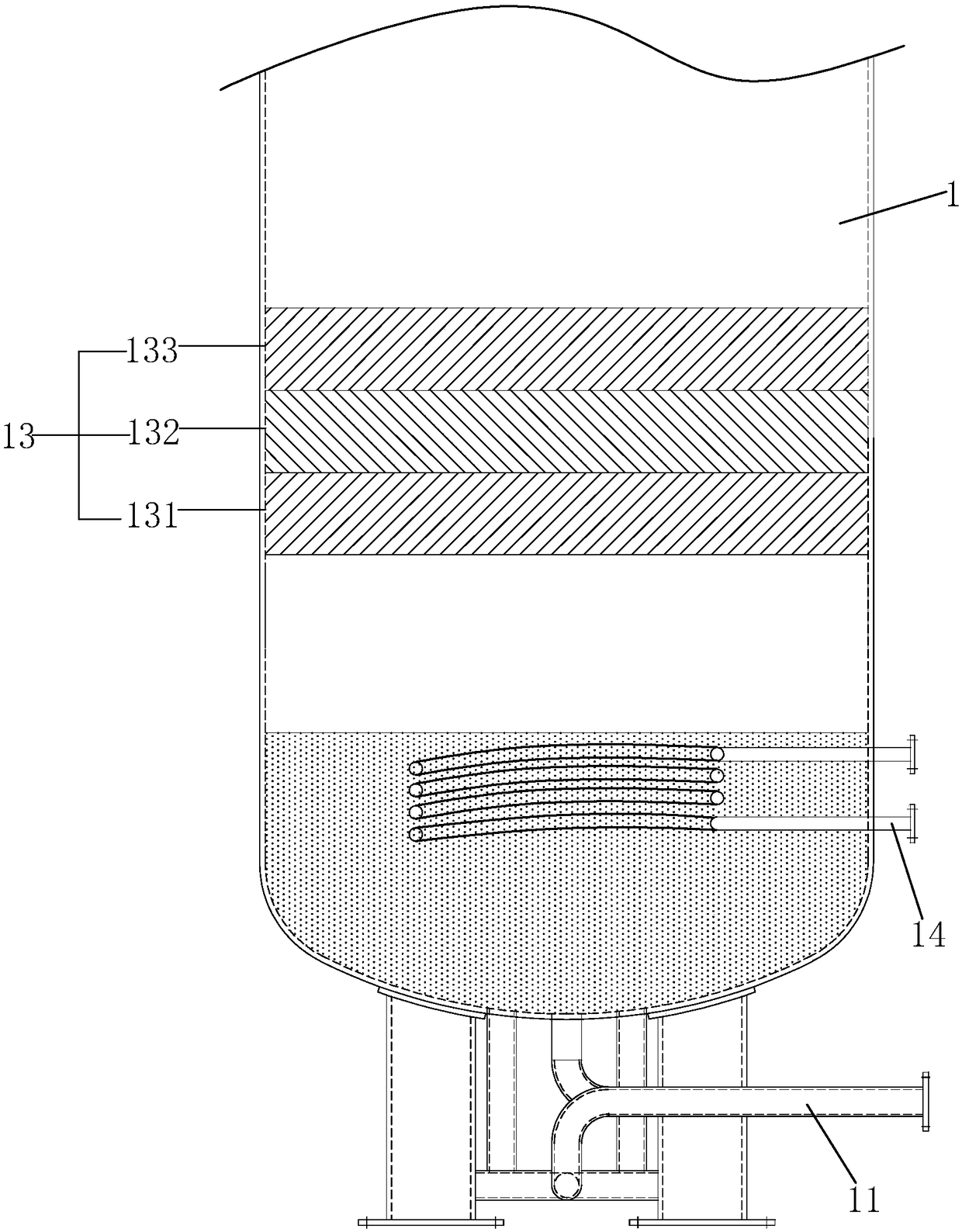

[0068] A kind of preparation equipment of hydrogen energy clean fuel, such as figure 1 As shown, it includes a gas production tank 1 and a material storage tank 2. The lower part of the gas production tank 1 is connected with an air intake pipe 11 for venting air, and the top of the gas production tank 1 is provided with a return pipe 12 connected to the material storage tank 2. The height of the end of the pipe 12 close to the gas production tank 1 from the ground is equal to or higher than the height of the end of the return pipe 12 close to the storage tank 2 from the ground, so that even if the mixed gas is cooled to form liquid during circulation, it is difficult to flow into the gas production tank 1. It is not easy to affect the quality of the stable mixed gas; the upper part of the storage tank 2 is also provided with an outlet pipeline 21 for outputting the mixed gas. The return pipe 12 communicates with the top of the storage tank 2, the air outlet pipe 21 is arrange...

Embodiment 5

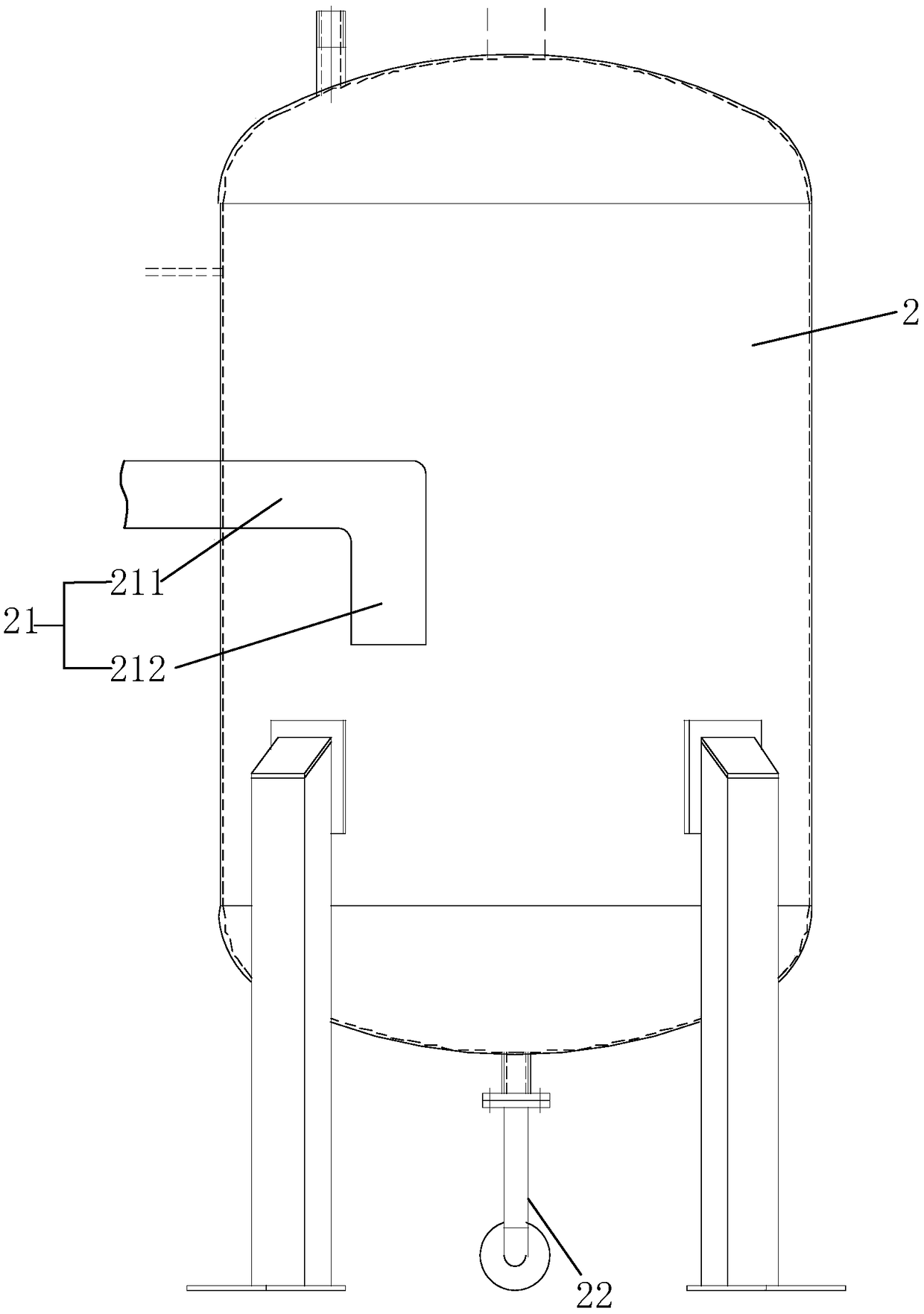

[0076] A kind of preparation equipment of hydrogen energy clean fuel, such as image 3 As shown, the difference between Embodiment 5 and Embodiment 4 is that the gas outlet pipeline 21 extends into the storage tank 2, and the part where the gas outlet pipeline 21 extends into the material storage tank 2 is provided with a bend, and the gas outlet pipeline 21 extends into the storage tank 2. The end of the tank 2 is open towards the bottom of the storage tank 2 .

[0077] In this embodiment, the part of the outlet pipe 21 extending into the material storage tank 2 includes an extending section 211 and a bent section 212, the central axes of the extending section 211 and the bent section 212 form a 90° angle, and the bent section 212 extends into the storage tank. The end opening of the material tank 2 is towards the bottom of the storage tank 2 .

[0078] Therefore, the mixed gas that enters the storage tank 2 from the return pipe 12 enters the bending section 212, and the liq...

Embodiment 6

[0080] A kind of preparation equipment of hydrogen energy clean fuel, such as Figure 4 As shown, the difference between Embodiment 6 and Embodiment 4 is that the bottom of the storage tank 2 is provided with a liquid inlet pipe 23 communicating with the gas production tank 1, which can directly discharge the cooling liquid in the storage tank 2 to the gas production tank. 1, the operation is more convenient, and it is not easy to cause waste, and it is more energy-saving and environmentally friendly.

[0081] In order to make the output and supply of mixed gas more stable, a gas storage tank 5 is communicated between the storage tank 2 and the gas outlet pipeline 21 .

[0082] The air intake pipeline 11 is connected with the air compressor 4, and the air intake pipeline 11 is connected with the dryer 41, the moisture of the air entering is small, it is not easy to affect the liquefaction of the liquid in the gas production tank 1, and the quality of the mixed gas produced is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com