A biogas fermentation method for pretreatment of straw

A biogas fermentation and pretreatment technology, applied in fermentation, waste fuel and other directions, to achieve the effect of less addition, mild pretreatment conditions, simple and safe use method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The total volume of the anaerobic fermentation reactor is 500mL, and the amount of rice straw crushed to about 20 mesh is 20gTS. The pretreatment reagent used is AlMgCu alloy powder with a particle size of 200 mesh. The composition of the AlMgCu alloy powder is Al:90~95% , Mg: 2~10%, Cu: 2~10%, the inoculum is pig manure digestive juice, the addition amount is about 6.67gTS, and the addition ratio is rice straw TS: inoculum TS=3:1.

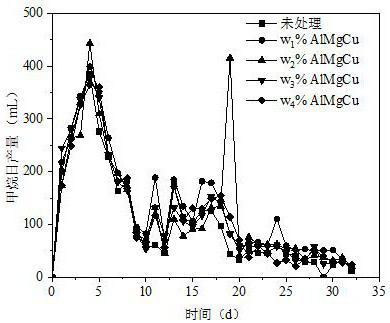

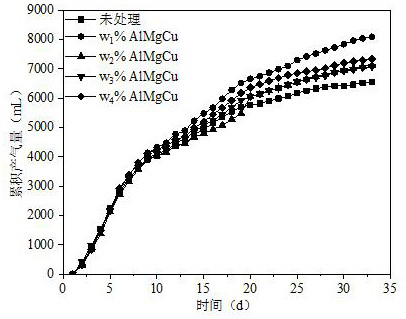

[0032] Weigh 20g TS of straw into a ziplock bag, add the mass fraction (relative to the mass of straw TS) from low to high as w 1 %,w 2 %,w 3 %,w 4 % AlMgCu alloy powder, add 6 times (relative to straw TS quality) water, mix and seal, heat in a water bath at 20-50°C, inoculate anaerobic digested sludge after 3 days, and start anaerobic fermentation. Transfer the pretreated rice straw and inoculum to a self-made anaerobic fermentation device, the volume of the fermentation bottle is 500mL, add water to the effective volume of 400mL, add C...

Embodiment 2

[0038] AlMgCu alloy powder with content of Al: 80-90%, Mg: 5-10%, Cu: 5-10% is used as the pretreatment agent, and the alloy particle size is 200 mesh.

[0039] Weigh two parts of 20gTS of straw into a ziplock bag, add 6 times of water, and add a part of straw to the mass fraction of straw TS w 1% (same as w in implementation case 1 1 %) of AlMgCu, after adding water and stirring well, select T from low to high 1 (20~30℃), T 2 (30~40℃) and T 3 (40-50°C) heated in a water bath at three temperatures, and one part without pretreatment was used as the control group. After 3 days, inoculate the pig manure digestive solution, add water to the maximum working volume of the fermentation bottle of 400mL, and start the fermentation.

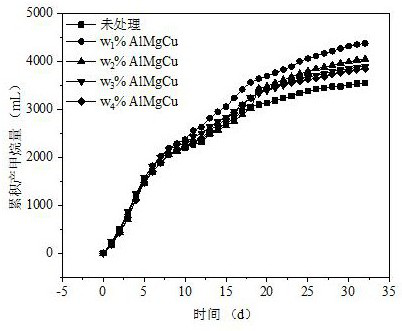

[0040] Figure 4 In order to accumulate the methane production map, it can be seen from the figure that the AlMgCu alloy powder in this case can improve the methane production capacity of straw under low temperature pretreatment. As the temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com