Enhanced low-tightness carbonization-free solid electrolytic capacitor paper and preparation method thereof

A technology of electrolytic capacitor paper and solid-state electrolysis, applied in pulp beating/refining methods, special paper, paper, etc., can solve the problems of negative and anode foil structure damage, insufficient strength of solid electrolytic capacitor paper, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

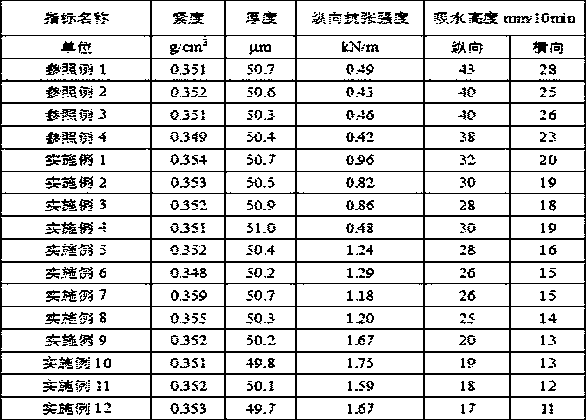

Examples

example 2

[0026] Manila hemp pulp is deflagged by a double-disc mill beater, and the debonding concentration is 4%. The beating degree and wet weight after deflaking are 17°SR and 27.5g respectively; The length is 5mm and the fineness is 1.0dtex. Mix the two kinds of fibers. After mixing, Manila hemp pulp and PET polyester fiber account for 40% and 60% of the total fiber dryness respectively. After mixing, the slurry concentration is 1%. Forming, forming on the Internet with a concentration of 0.05%, and then obtaining the finished product after pressing, drying, coiling and slitting.

[0027] Reference example 3

[0028] The sisal pulp was deflagged with a double-disc mill beater, and the debonding concentration was 4%. The beating degree and wet weight after deflaking were 15°SR and 15.3g respectively; after the PET polyester fiber was dispersed, the pulp concentration was 2%, and the fiber The length is 5mm and the fineness is 0.5dtex. Mix the two kinds of fibers. After mixing, Ma...

example 4

[0030] The sisal pulp was deflagged with a double-disc mill beater, and the debonding concentration was 4%. The beating degree and wet weight after deflaking were 15°SR and 15.3g respectively; after the PET polyester fiber was dispersed, the pulp concentration was 2%, and the fiber The length is 5mm and the fineness is 1.0dtex. Mix the two kinds of fibers. After mixing, Manila hemp pulp and PET polyester fiber account for 40% and 60% of the total fiber dryness respectively. After mixing, the slurry concentration is 1%. Forming, forming on the Internet with a concentration of 0.05%, and then obtaining the finished product after pressing, drying, coiling and slitting.

Embodiment 1

[0032] Manila hemp pulp is beaten with a double-disc mill beater, the beating concentration is 4%, and the beating degree and wet weight after beating are 70°SR and 14g respectively; after the PET polyester fiber is dispersed, the pulp concentration is 2%, and the fiber The length is 5mm and the fineness is 0.5dtex. Mix the two kinds of fibers. After mixing, Manila hemp pulp and PET polyester fiber account for 50% and 50% of the total fiber dryness respectively. After mixing, the slurry concentration is 1%. Forming, forming on the Internet with a concentration of 0.05%, and then obtaining the finished product after pressing, drying, coiling and slitting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com