Temperature control valve for controlling cooling water flow of air cylinder of piston type compressor

A cooling water flow and control cylinder technology, applied in the field of compressors, can solve the problems of human misoperation risk, insufficient cooling, high cost, etc., to achieve convenient direct connection and installation direction identification, compact structure, low manufacturing and operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

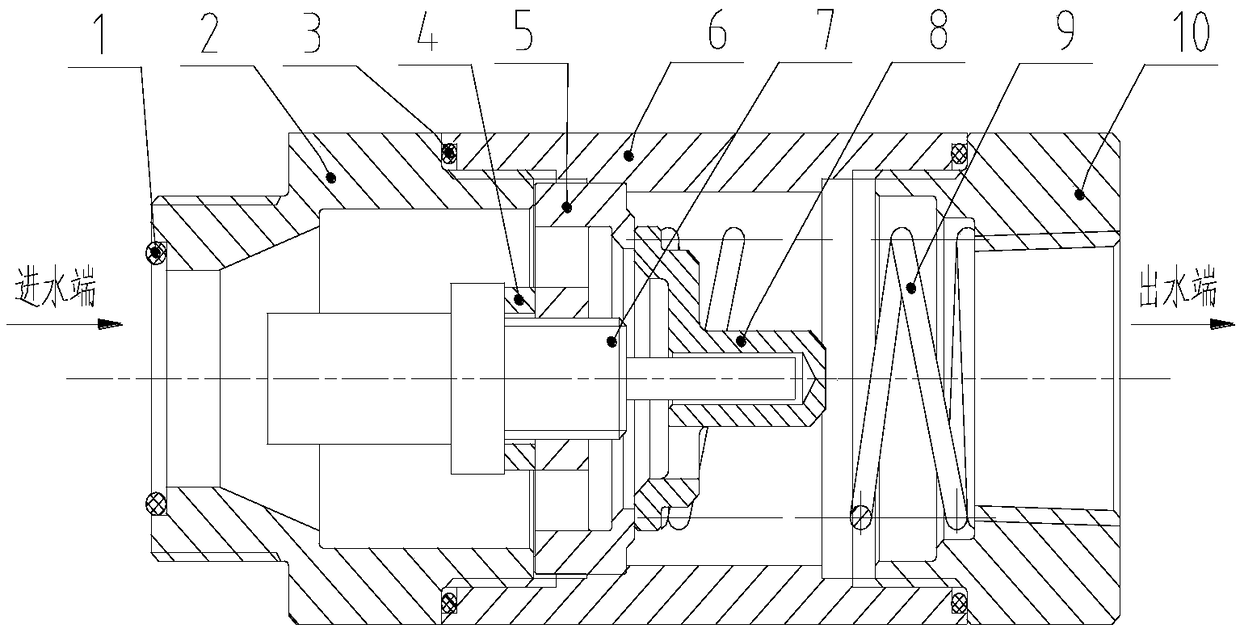

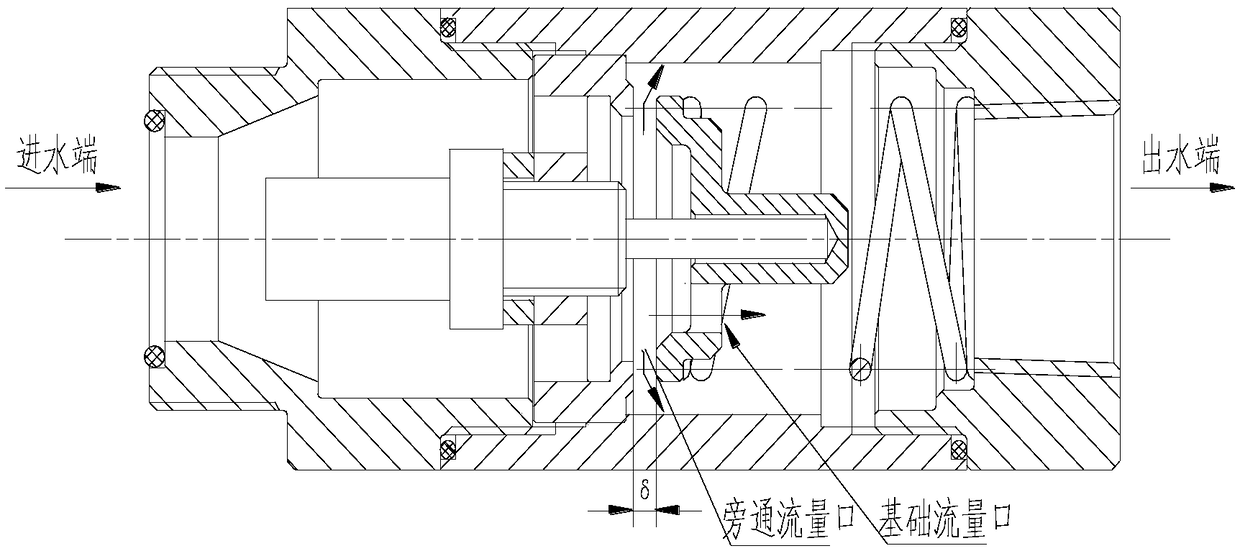

[0027] combine Figure 1-Figure 6 , in this embodiment of the present invention, in the description of the relevant representative orientation, the direction of water flow refers to the direction from the water inlet end to the water outlet end, and the "head" and "tail" are headed according to the water flow direction close to the water inlet end. The tail is close to the water outlet, and the "upper end" and "lower end" refer to the upper and lower positions of the components in the schematic diagram of the corresponding components. Other understandings of the words indicating orientation in this application and that do not affect the functions of this application are also regarded as technical solutions of this application.

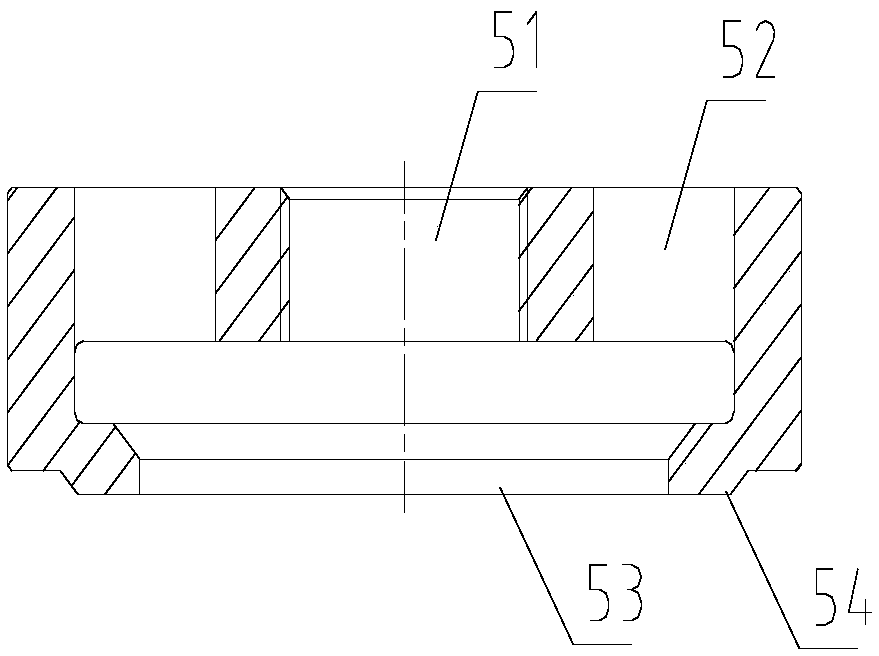

[0028] A temperature control valve for controlling the cooling water flow of a cylinder of a piston compressor, comprising a first O-shaped sealing ring 1, a first cover nut 2, a temperature sensing element 7, a water diversion plate 5, a valve body 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com