A kind of detection method of cmc content in printing paste for printing and dyeing

A printing paste and detection method technology, which is applied in the preparation of test samples, measuring devices, and analysis materials, can solve the problems of weaving and dyeing defects, waste of printing paste, and high weaving and dyeing costs, and achieve fast calculation speed and process Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

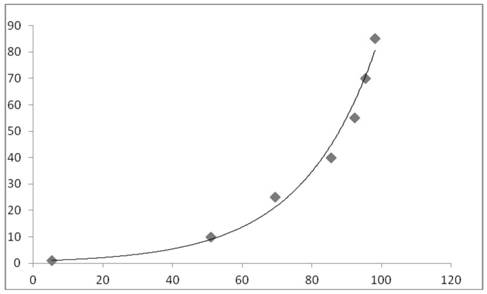

Image

Examples

Embodiment 1

[0047] This embodiment provides a printing paste, which is composed of the following raw materials in weight percentage: 25% sodium alginate, 15% additives (the weight ratio of sodium hexametaphosphate: sodium sulfate is 0.7:3) and 60% cmc.

[0048] Use the method provided by the invention to detect the cmc content in the above-mentioned printing paste, the steps are as follows:

[0049] S1, first beat the printing paste solution with pure water, the beating process is as follows:

[0050] Weigh 500g of printing paste solution with a concentration of 6%, put it in a beating mixer, set the rotation speed of the agitator to 600r / min, and stir for 1.5h, take it off, let it stand until no bubbles overflow, and obtain a beating solution ;

[0051] S2, the beating solution obtained in S1 is enzymatically hydrolyzed by enzymatic hydrolysis, and the enzymatic hydrolysis process is as follows:

[0052]Add 0.09 g of cellulose compound enzyme to the beating solution obtained in S1, the...

Embodiment 2

[0064] A kind of detection method of cmc content in printing paste for printing and dyeing, the steps are as follows:

[0065] S1, first beat the printing paste solution with pure water, the beating process is as follows:

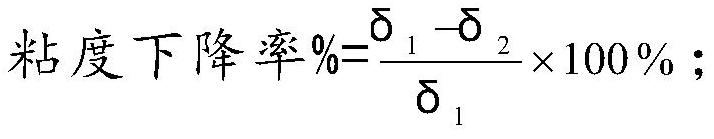

[0066] Take by weighing 500g of printing paste solution with a concentration of 20%, place it in a beating mixer, set the rotating speed of the agitator to 600r / min, and stir for 1h, take it off, leave it to stand until no bubbles overflow, and obtain the beating solution. Measure the viscosity of the beating solution at 20°C and record it as δ 1 ;

[0067] S2, the beating solution obtained in S1 is enzymatically hydrolyzed by enzymatic hydrolysis, and the enzymatic hydrolysis process is as follows:

[0068] Add 0.3g of cellulose compound enzyme to the beating solution obtained in S1, then manually stir for 10 minutes, and let it stand for half an hour to obtain the enzymolysis solution, measure the viscosity of the enzymolysis solution at 20°C, and recor...

Embodiment 3

[0094] This embodiment provides a kind of printing paste, which is composed of the following raw materials in weight percentage: sodium alginate 12%, additive 15% (the weight ratio of sodium hexametaphosphate: sodium sulfate is 0.5:3) and cmc 73%.

[0095] Use the following method to measure the content of cmc in the above-mentioned printing paste, the steps are as follows:

[0096] S1, first beat the printing paste solution with pure water, the beating process is as follows:

[0097] Take by weighing 500g of printing paste solution with a concentration of 10%, place it in a beating mixer, set the rotating speed of the agitator to 500r / min, and stir for 1h, take it off, leave it to stand until no bubbles overflow, and obtain the beating solution. Measure the viscosity of the beating solution at 20°C and record it as δ 1 ;

[0098] S2, the beating solution obtained in S1 is enzymatically hydrolyzed by enzymatic hydrolysis, and the enzymatic hydrolysis process is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com