Test method for lithium ion battery ceramic diaphragm porosity

A technology of lithium-ion batteries and ceramic diaphragms, which is applied in the fields of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of poor mechanical properties, cumbersome process, and large impact, and achieve test equipment And the effect of low condition requirements, strong operability and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of lithium-ion battery ceramic diaphragm in the specific embodiment comprises the following steps:

[0026] 1) The raw material PP is melted and extruded, and then heat-treated to obtain a polyolefin film after cooling; the pore size of the polyolefin film is between 40 and 100 nm;

[0027] 2) The polyolefin film is stretched longitudinally and transversely, and cut and rolled after heat setting;

[0028] 3) Place the wound-up base film on a coating machine, and coat the ceramic slurry on the surface of the diaphragm to obtain a ceramic coated diaphragm; the ceramic slurry includes alumina particles and a binder, alumina particles and adhesive The mass ratio of the binder is 99:1, and the binder used is a water-based polyacrylic binder; the average particle size of the alumina particles is 0.5 μm.

Embodiment 1

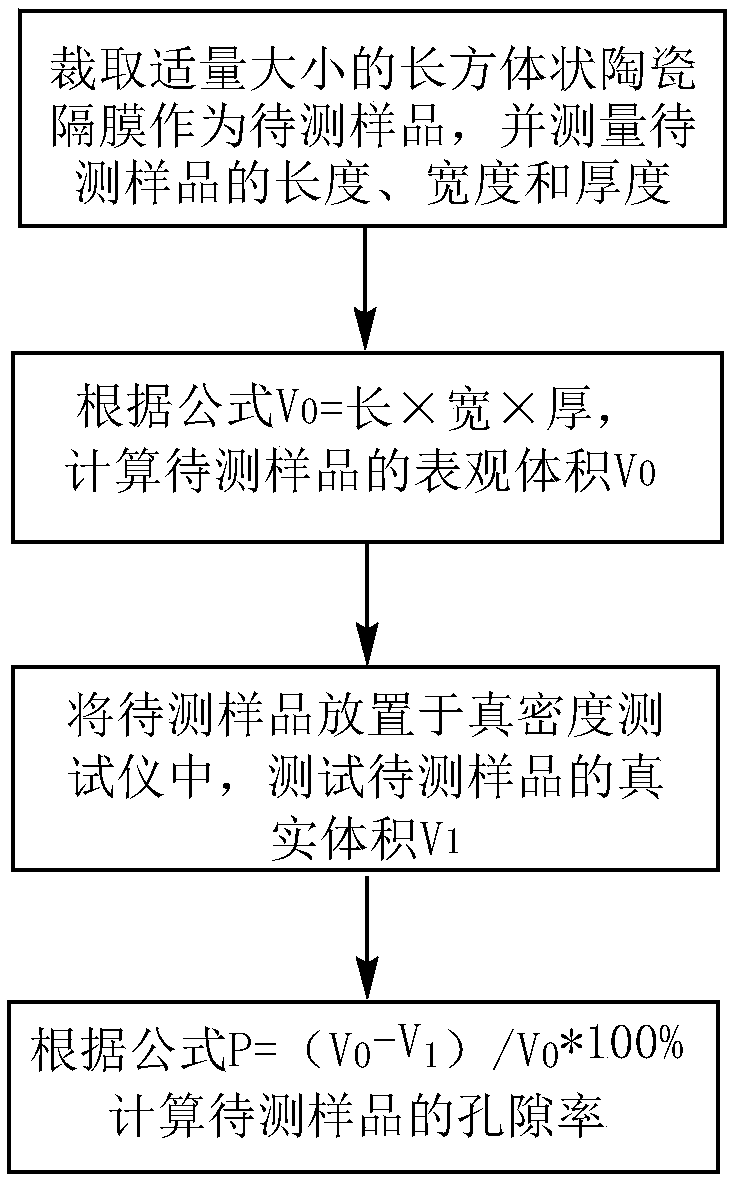

[0030] The test method of the porosity of the lithium-ion battery ceramic diaphragm of the present embodiment, the flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0031] 1) Take the lithium-ion battery ceramic diaphragm, and use a knife along the steel ruler to cut out a cuboid lithium-ion battery ceramic diaphragm of an appropriate size as the sample to be tested;

[0032] Measure the length and width of the cuboid-shaped sample to be tested with a steel ruler, and measure the thickness of the cuboid-shaped sample to be tested with a micrometer (measure the average value of the thickness multiple times), according to V 0 = length × width × thickness, calculate the apparent volume V of the sample to be tested 0 ;

[0033] 2) Place the sample to be tested in a blast drying oven at 60°C for 1 hour, then place it in a desiccator for natural cooling, put the sample to be tested in a real density meter, and measure the real volume. The...

Embodiment 2

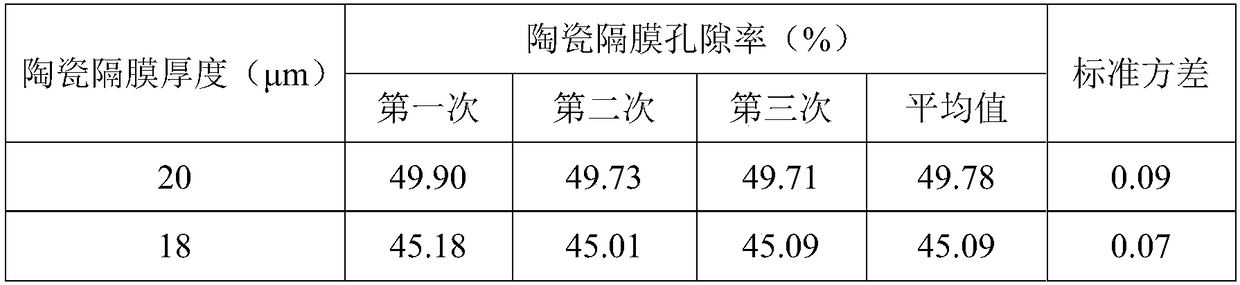

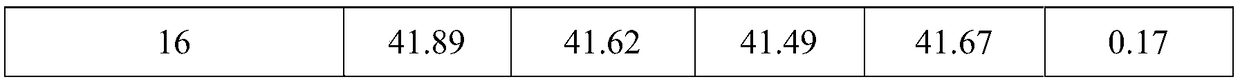

[0036] Three lithium-ion battery ceramic separators with a thickness of about 20 μm, 18 μm and 16 μm were respectively selected, and the porosity data obtained by the test were shown in Table 1 according to the test method for the porosity of the lithium-ion battery ceramic separator in Example 1.

[0037] Table 1 Porosity of Li-ion battery ceramic separators with three different specifications

[0038]

[0039]

[0040] As can be seen from the data in the above table, the data error obtained by the test method of the porosity of lithium-ion battery ceramic diaphragm of the present invention is smaller, the data is more accurate, and the test process is simple, convenient and fast, and the requirements for equipment are relatively low. The inventive testing method for the porosity of the ceramic diaphragm is stable and reliable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com