Reactor pressure vessel experimental simulation body for pressurized water reactor water loss accident

A pressure vessel and experimental simulation technology, applied in the field of nuclear power, can solve the problems of high sealing cost and invariance, and achieve the effect of reducing sealing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

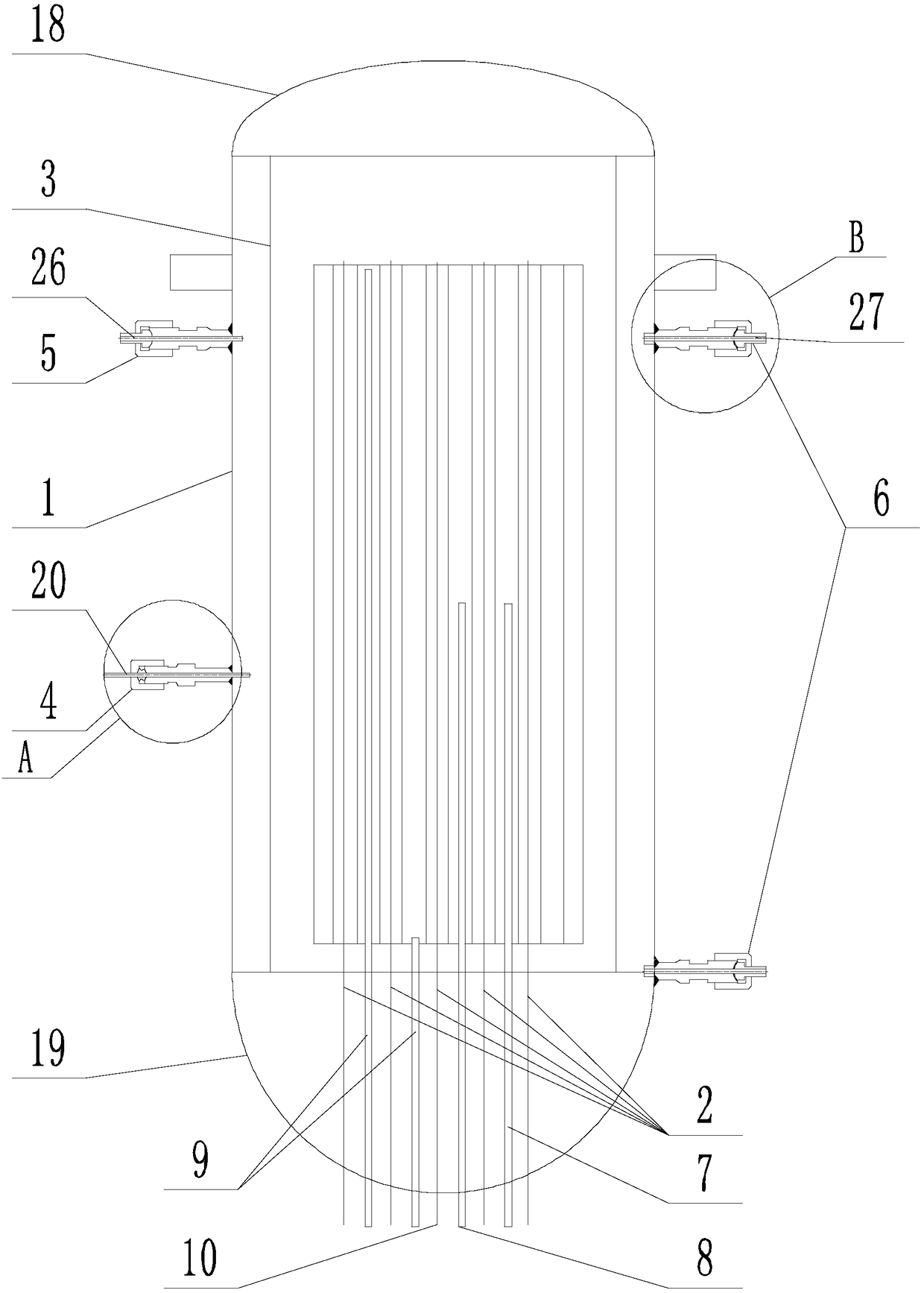

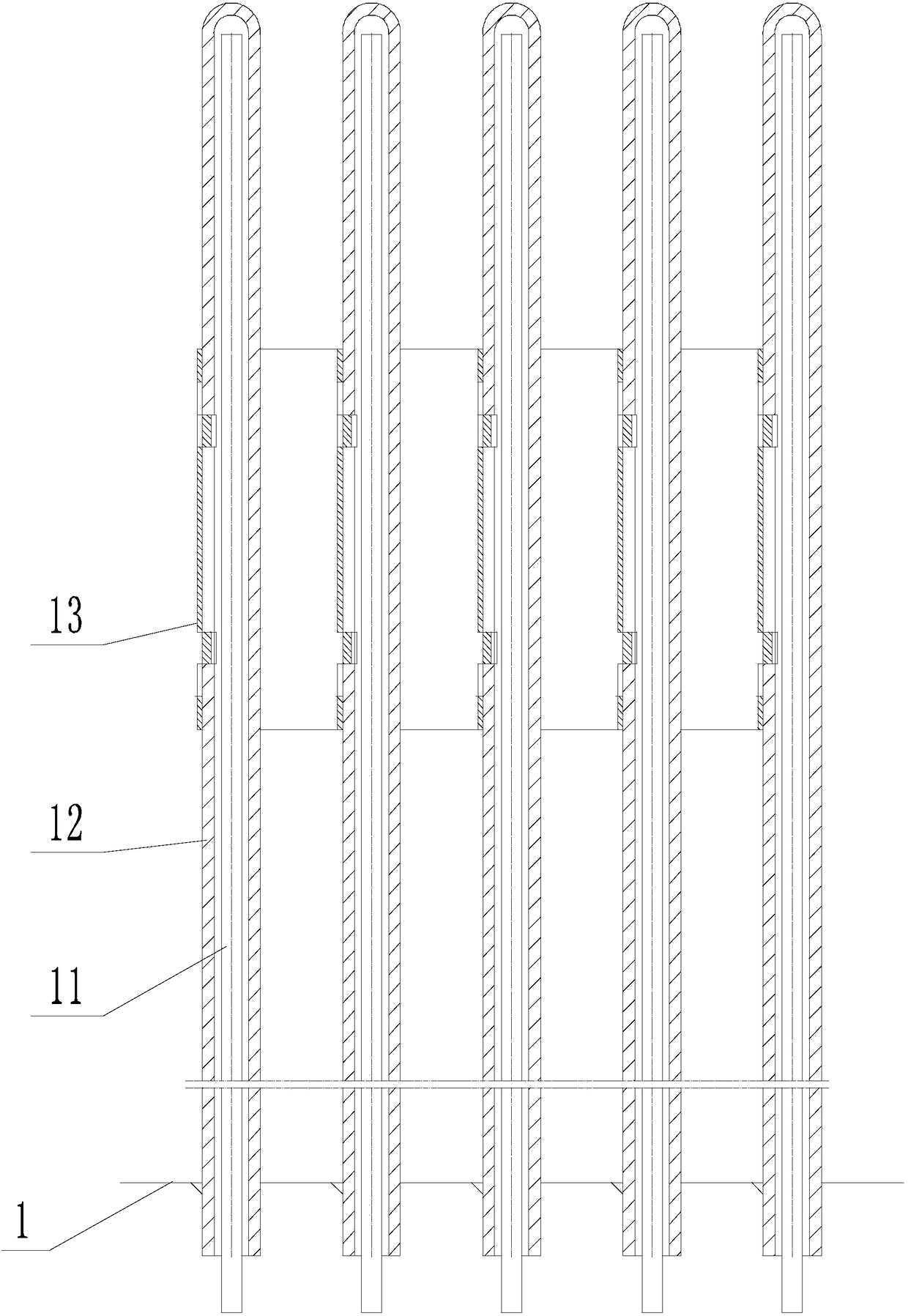

[0051] Such as Figure 1-Figure 8 As shown, the reactor pressure vessel experiment simulation body used for the pressurized water reactor loss of water accident of the present invention includes a reactor pressure vessel experiment simulation body body and a core detection device, and the reactor pressure vessel experiment simulation body body includes a pressure vessel simulation body and The spider plant simulation body 3 located in the inner cavity of the pressure vessel simulation body is provided with a core assembly simulation body in the spider plant simulation body. The pressure vessel simulation body includes an upper head 18, a middle cylindrical body 1 and a lower head 19 welded in sequence. The core assembly simulation body includes a cladding tube 12, an electric heating element 11 placed in the cladding tube 12, and a positioning grid 13 for fixing each cladding tube 12, and the core detection device is used for collecting the core during experiments. Parameter i...

Embodiment 2

[0056] This embodiment is based on Embodiment 1, and further describes an implementation manner of a core detection device.

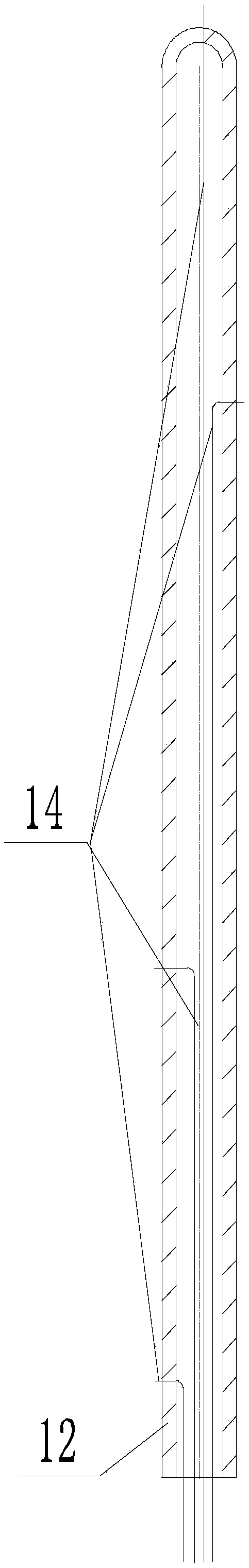

[0057] Such as image 3 As shown, the present invention is used for the reactor pressure vessel experiment simulation body of the pressurized water reactor loss of water accident, and the core detection device includes a coolant temperature measuring assembly 7 in the core, and The temperature measuring end of the core thermocouple 14 is inserted from the opening end of the cladding tube 12, and the end of the temperature measuring end passes through the tube wall of the cladding tube 12 with a length of 1 mm, and is located in the same cladding tube 12 There are several core thermocouples 14 inside, and the locations where the temperature is collected are distributed along the axis of the cladding tube 12 .

[0058] The end of the temperature measuring end passes through the tube wall of the cladding tube 12 , so that the temperature measuring end can...

Embodiment 3

[0067] This embodiment is based on the embodiment 1, and further describes the second embodiment of the core detection device.

[0068] Such as Figure 4 As shown, the present invention is used for the reactor pressure vessel experiment simulation body of the pressurized water reactor loss of water accident, and the core detection device includes a coolant pressure measurement assembly 8 in the core, and One end of the core pressure induction tube I15 is connected to the signal receiving end of the intelligent pressure transmitter, the other end of the core pressure induction tube I15 is inserted from the open end of the cladding tube 12, and the end of this end is connected from the cladding tube 12 The wall of the pipe is pierced, and the length of the piercing is 1mm.

[0069] Similarly, the end of the core pressure induction tube I15 passes through the tube wall of the cladding tube 12, so that the temperature measuring end can be fixed by welding the part where the core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com