Block copolymer used for specific nanostructure construction in epoxy resin and application of block copolymer in preparation of high toughness composite material

A technology of block copolymer and epoxy resin, which is applied in the direction of epoxy resin coating, epoxy resin glue, adhesive type, etc., can solve the problem of poor impact resistance and peeling resistance, insufficient toughness of EP cured products, molecular chain Not easy to slide and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

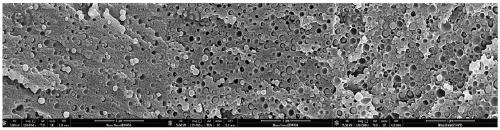

[0036] Embodiment 1, preparation and performance detection of composite material of the present invention

[0037] One, the preparation of composite material of the present invention

[0038] 1. Experimental materials and reagents

[0039] Bisphenol A glycidyl ether epoxy resin E-51 (DGEBA), purchased from Jiangsu Wuxi Resin Factory;

[0040] 3,3'-dichloro-4,4'-diaminodiphenylmethane (MOCA), purchased from Changshan Bell Co., Ltd.;

[0041] Monohydroxyl-terminated polydimethylsiloxane (PDMS-OH) was provided by Shin-Etsu Chemical Co., Ltd., Japan. Adopt anhydrous toluene azeotropic distillation before use;

[0042] ε-caprolactone (ε-CL), purchased from Aladdin, 99%, treated with calcium hydride (CaH 2 ) after drying, distillation under reduced pressure;

[0043] Stannous octoate (Sn(Oct) 2 ), purchased from Aladdin.

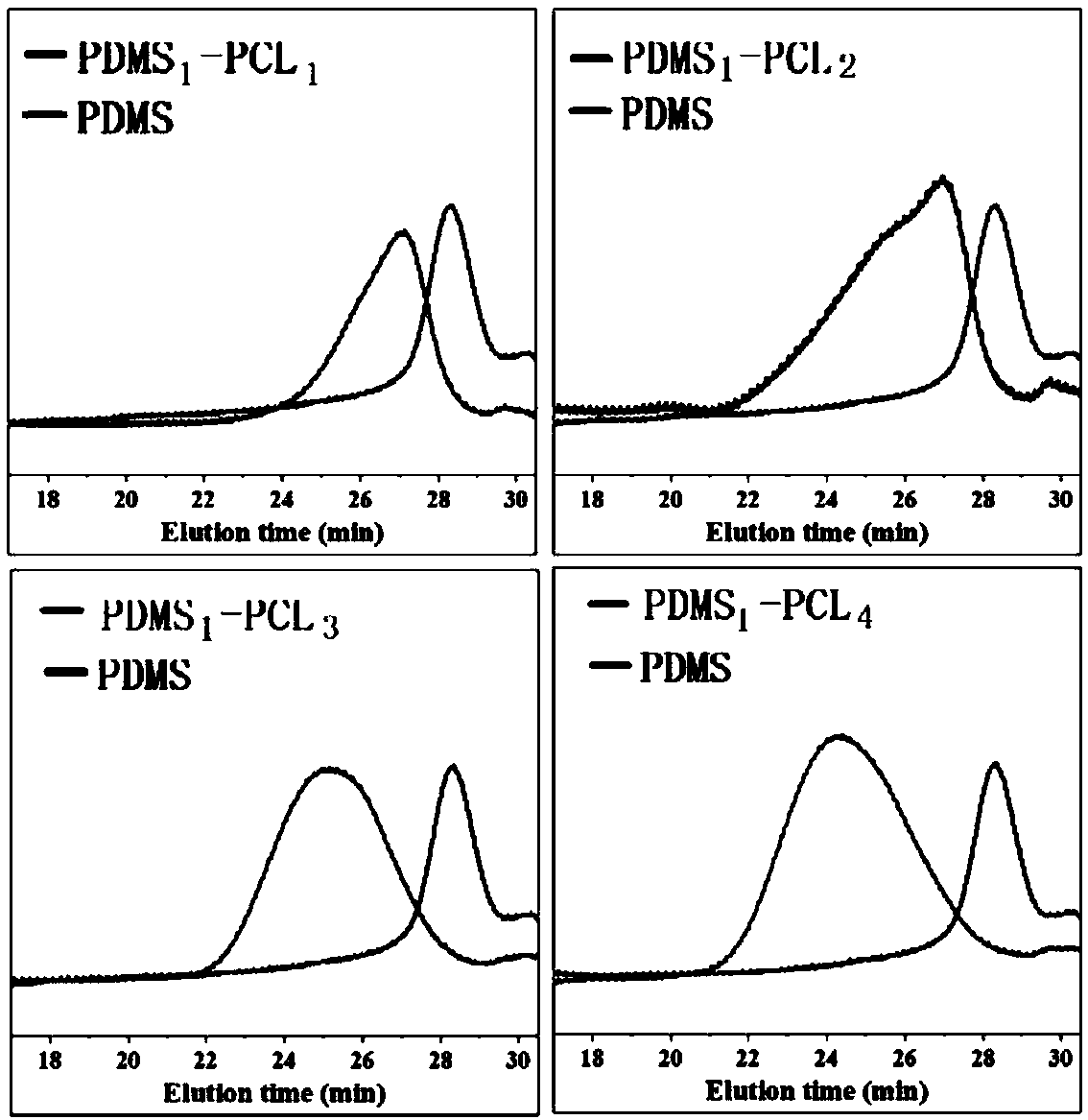

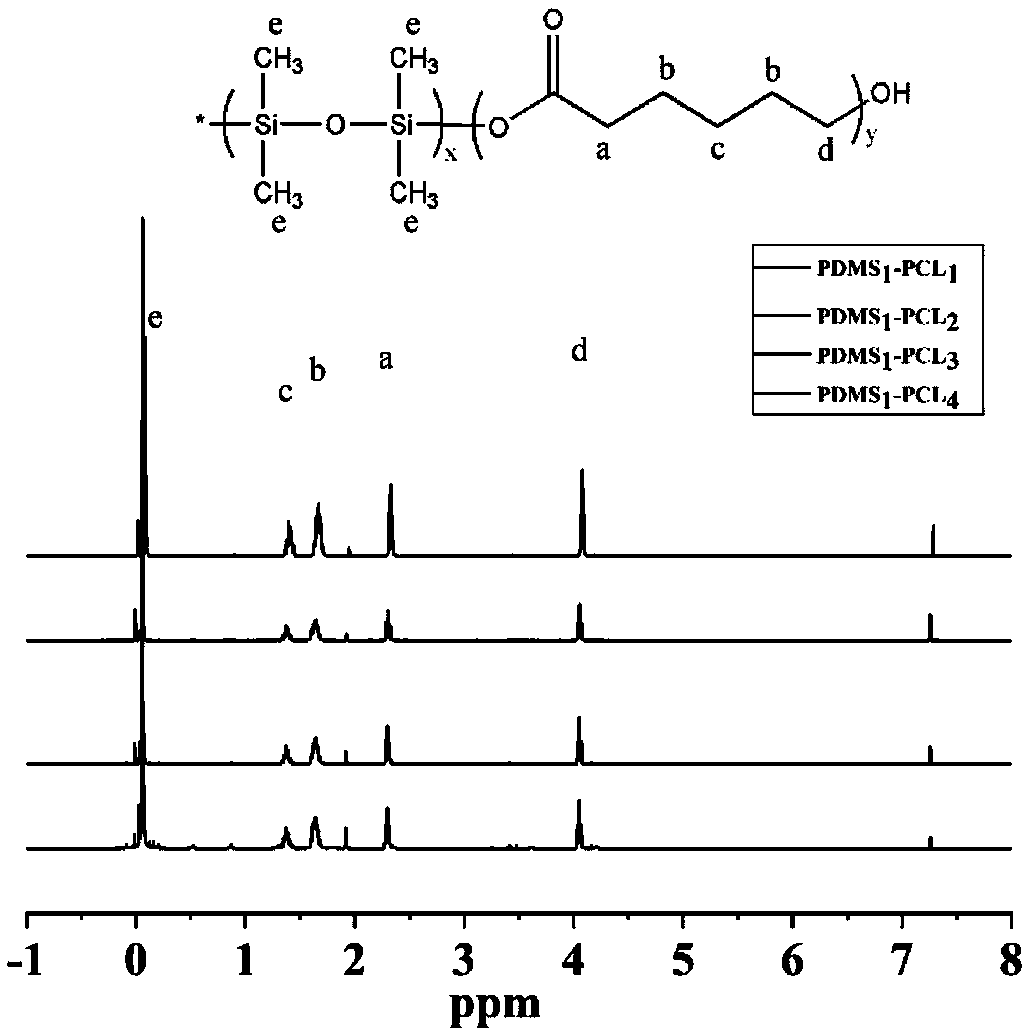

[0044] 2. Synthesis of Diblock Copolymer PDMS-b-PCL

[0045]

[0046] Add the polydimethylsiloxane PDMS-OH and caprolactone monomer and 0.1%wt stannous o...

Embodiment 2

[0090] The PDMS-PCL / EP composite material prepared in Example 1 is used as the matrix resin, and the commonly used modifiers in the fields of coatings, electrical materials, casting packaging materials, adhesives, sealants, etc. are prepared to prepare coatings, electrical materials, Pouring packaging materials, adhesives, sealants.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com