A high-efficiency and energy-saving hot blast furnace firing method

A high-efficiency, energy-saving, hot-blast stove technology, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as the impact of hot-blast stove life, high production costs, and large gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

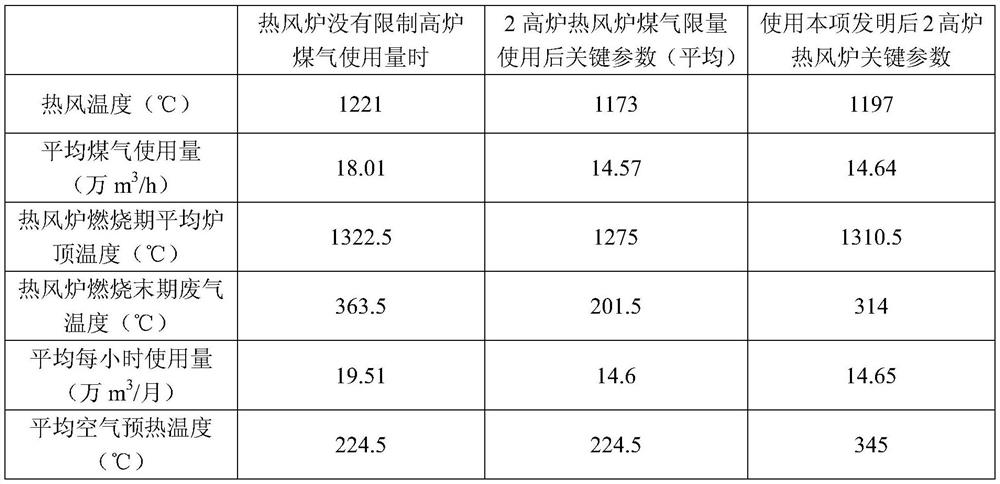

[0024] Anshan Iron and Steel No. 2 blast furnace hot blast stove is equipped with 4 Nippon Steel hot blast stoves and two top-fired preheating stoves to preheat the combustion air used in the combustion of the hot blast stove. The upper limit of the preheating of the combustion air used in the combustion of the hot blast stove is 350°C. The gas volume used by the hot blast stove for normal production reaches 18×10 4 m 3 / h, preheating the combustion-supporting air to 160°C can meet the blast furnace's air temperature requirement of 1225°C. But now the hot stove can only use 15×10 4 m 3 / h blast furnace gas, gap 3×10 4 m 3 / h, according to the normal firing method, the heat storage of the hot blast stove will gradually decrease, not only the temperature of the hot blast will drop sharply, but also there will be large fluctuations during the furnace replacement cycle, and the temperature of the lower, middle and upper parts of the hot blast stove will drop sharply At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com