Micro-oxygen-enriched combustion boiler system

An oxygen-enriched combustion and boiler technology, applied in the field of boiler systems, can solve problems such as not being used well, and achieve the effects of increasing theoretical combustion temperature, reducing investment and energy consumption, and optimizing combustion conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with specific embodiment, further illustrate the present invention.

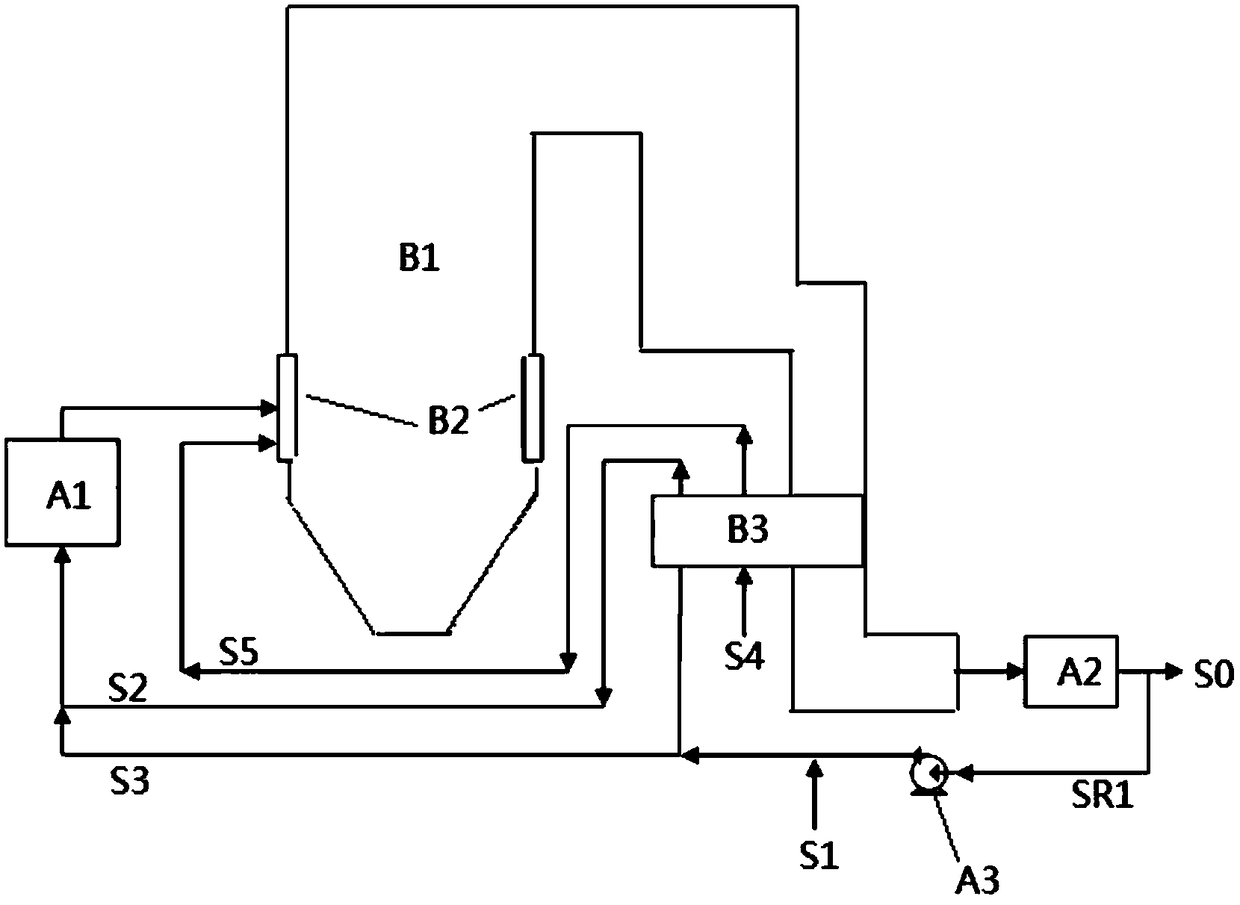

[0026] figure 1 The schematic diagram of the micro-oxygen-enriched combustion boiler system provided for this embodiment, the micro-oxygen-enriched combustion boiler system includes the boiler body, pulverizing equipment A1, flue gas treatment equipment A2, recirculation fan A3 and connecting pipes in the boiler system and valves etc.

[0027] The boiler body includes a furnace B1, a burner B2 and a heating surface including a gas preheater B3. After the flue gas discharged from the boiler body flows through the flue gas treatment equipment A2, part of it is exhausted from the boiler system as boiler exhaust S0, and the other part is used as recirculation primary air SR1; the recirculation primary air SR1 is pressurized by recirculation fan A3 and combined The primary air supplementary gas S1 is mixed, and then the mixed gas formed is divided into two paths: one path is heated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com