A method for manufacturing a high-toughness high-strength aluminum alloy wheel hub for automobiles

A technology of an aluminum alloy wheel hub and a manufacturing method, which is applied in the directions of wheel hubs, vehicle parts, transportation and packaging, etc., can solve the problems of difficulty in meeting the requirements of high toughness and high strength of aluminum alloy wheels, room temperature tensile strength, low toughness, etc. The microstructure is uniform in density, the grain refinement is increased, and the slag removal effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

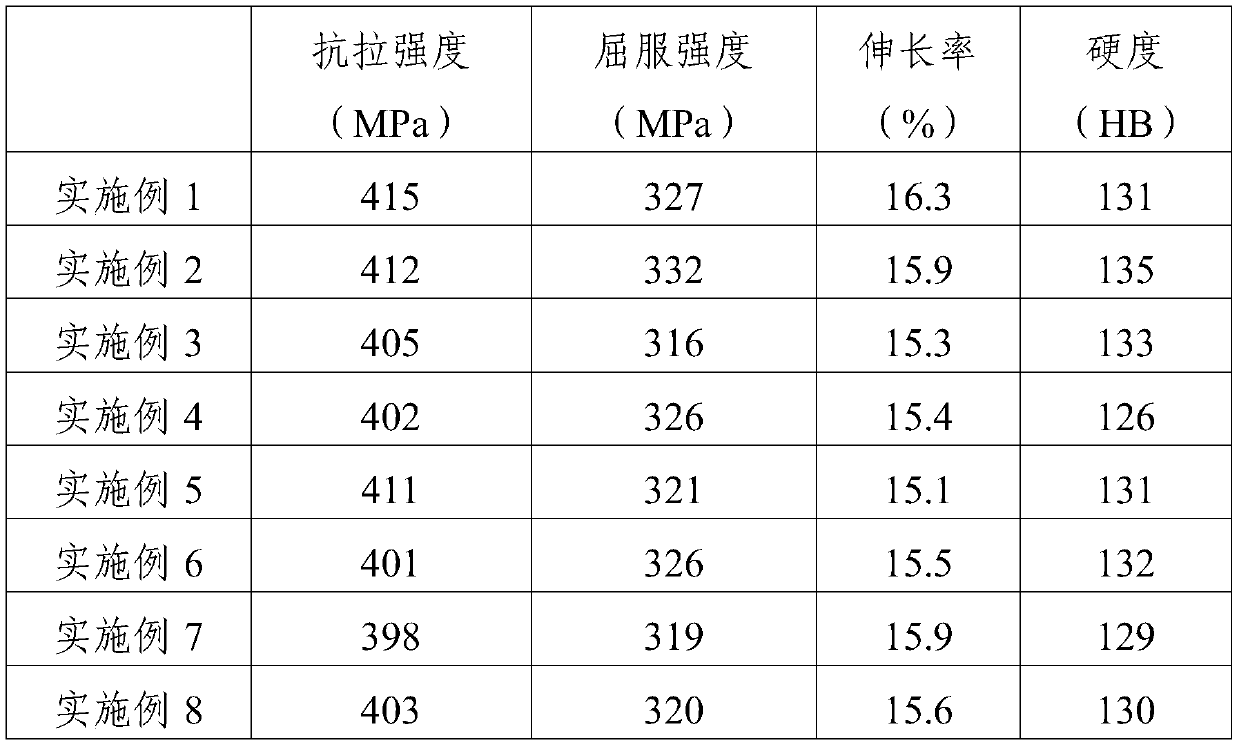

Examples

Embodiment 1

[0033] A high-toughness and high-strength aluminum alloy wheel hub for automobiles, the mass percentages of the components in the aluminum alloy wheel hub are: Si: 4.2%, Mg: 1.35%, Mn: 0.53%, V: 0.34%, Ti: 0.61%, Zr: 0.08%, RE: 0.08%, and the balance is Al; the RE is composed of Yb, Pr, Nd, and Sc, and the mass ratio of Yb, Pr, Nd, and Sc is 1:0.5:0.5:1.

[0034] A method for manufacturing a high-toughness high-strength aluminum alloy wheel hub for automobiles, comprising the following steps:

[0035] (1) Melting: put each raw material into a vacuum melting furnace for smelting. During the smelting process, ensure that the temperature of the molten aluminum is 780°C, measure the content of each element in the molten aluminum, and adjust the content of each element to meet the formula requirements;

[0036] (2) Refining: quickly skim off the scum on the surface of the aluminum liquid with a slag scraper, spray the refining agent into the aluminum liquid with a jet machine and u...

Embodiment 2

[0043] A high-toughness and high-strength aluminum alloy wheel hub for automobiles, the mass percentages of the components in the aluminum alloy wheel hub are: Si: 3.8%, Mg: 1.63%, Mn: 0.62%, V: 0.46%, Ti: 0.52%, Zr: 0.11%, RE: 0.1%, and the balance is Al; the RE is composed of Yb, Pr, Nd, and Sc, and the mass ratio of Yb, Pr, Nd, and Sc is 1:0.3:0.6:0.8.

[0044] A method for manufacturing a high-toughness high-strength aluminum alloy wheel hub for automobiles, comprising the following steps:

[0045] (1) Smelting: put each raw material into a vacuum melting furnace for smelting. During the smelting process, ensure that the temperature of the molten aluminum is 770°C, measure the content of each element in the molten aluminum, and adjust the content of each element to meet the formula requirements;

[0046] (2) Refining: quickly skim off the scum on the surface of the aluminum liquid with a slag scraper, spray the refining agent into the aluminum liquid with a jet machine and...

Embodiment 3

[0053] A high-toughness and high-strength aluminum alloy wheel hub for automobiles, the mass percentages of the components in the aluminum alloy wheel hub are: Si: 4.8%, Mg: 1.5%, Mn: 0.62%, V: 0.41%, Ti: 0.7%, Zr: 0.05%, RE: 0.05%, and the balance is Al; the RE is composed of Yb, Pr, Nd, and Sc, and the mass ratio of Yb, Pr, Nd, and Sc is 1:0.6:0.8:1.

[0054] A method for manufacturing a high-toughness high-strength aluminum alloy wheel hub for automobiles, comprising the following steps:

[0055] (1) Melting: put each raw material into a vacuum melting furnace for smelting. During the smelting process, ensure that the temperature of the molten aluminum is 780°C, measure the content of each element in the molten aluminum, and adjust the content of each element to meet the formula requirements;

[0056] (2) Refining: quickly skim off the scum on the surface of the molten aluminum with a slag scraper, spray the refining agent into the molten aluminum with a jet machine and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com