Process method for improving surface quality of quenched-and-tempered steel nitrided members

A technology of surface quality and process method, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of low hardness, porosity or brittleness, etc., to improve wear resistance, avoid accumulation, and improve corrosion resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

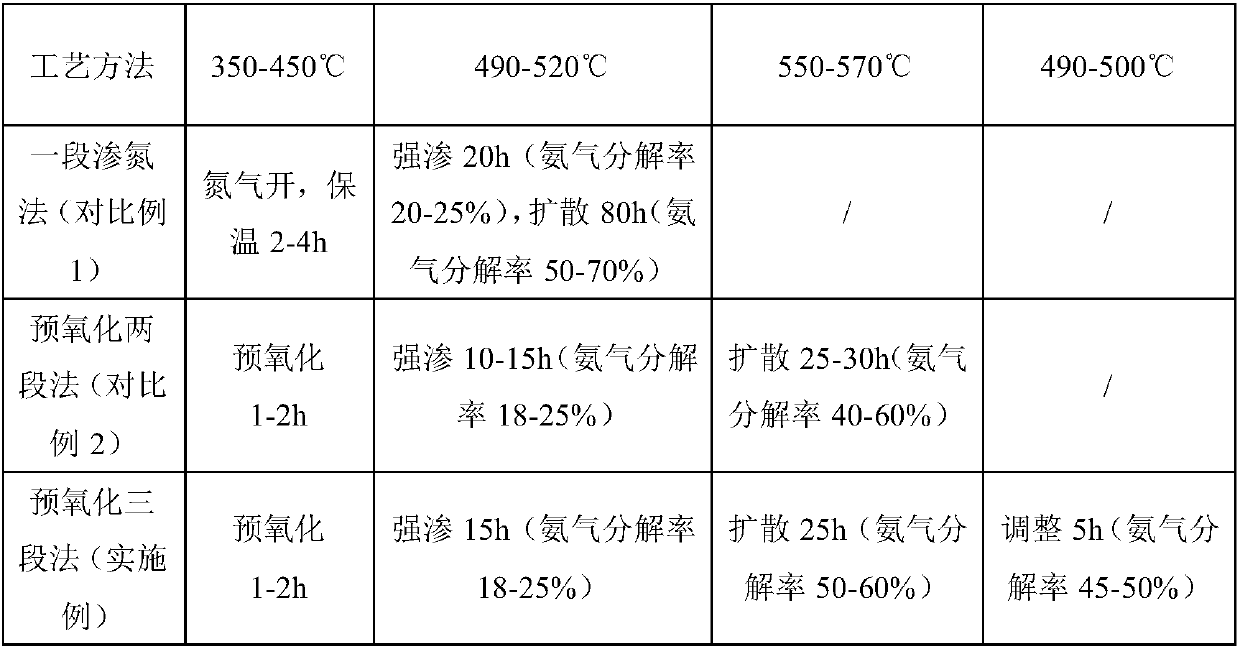

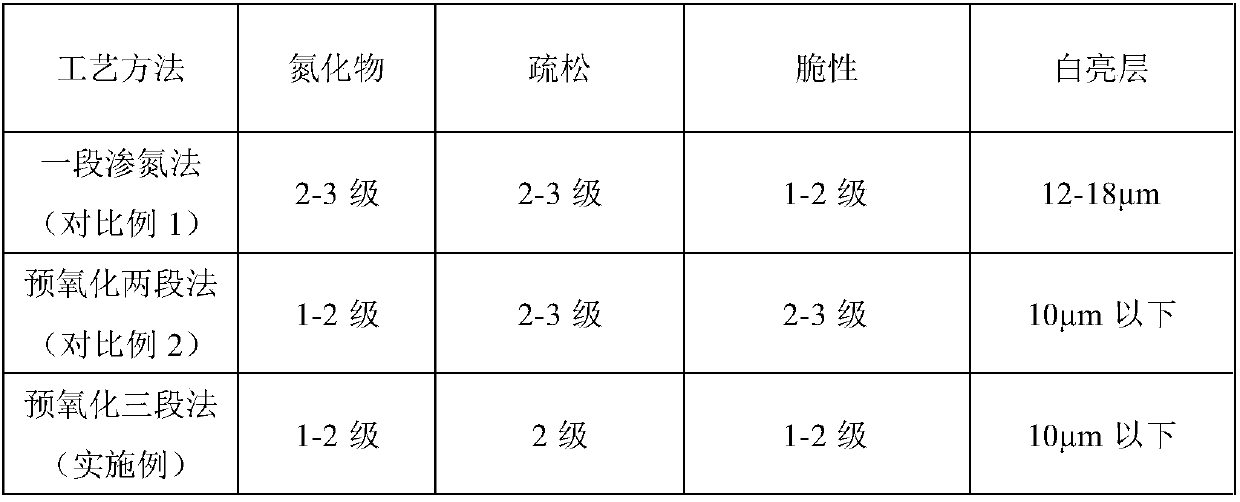

[0016] A process method for improving the surface quality of quenched and tempered steel nitriding parts adopts a pre-oxidation three-stage rapid nitriding process, specifically including three stages of hard nitriding strong infiltration, diffusion, and nitrogen supplementation. Among them, pre-oxidize for 1-2 hours before the strong infiltration stage, and the temperature is 350-450°C. In the strong infiltration stage, the temperature is 490-520°C, the time is 15 hours, and the decomposition rate of ammonia gas is 18-25%. The temperature in the diffusion stage is 550-570° C., the time is 25 hours, and the decomposition rate of ammonia gas is 50-60%. Adjust the temperature of the nitrogen supplementation stage to 490-500° C., the time is 5 hours, and the ammonia gas decomposition rate is 45-50%.

[0017] In order to highlight the beneficial effects of the process of the present invention, the following comparative experiments were also carried out, see Table 1 for details. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com