A kind of tree root stump lightweight retaining wall for road widening and construction method thereof

A technology for tree root stumps and retaining walls, which is applied to roads, roads, sheet pile walls, etc., can solve the problems of large construction space, low bulk density of foam light soil, many equipment processes, etc., so as to reduce the difficulty and improve the shear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

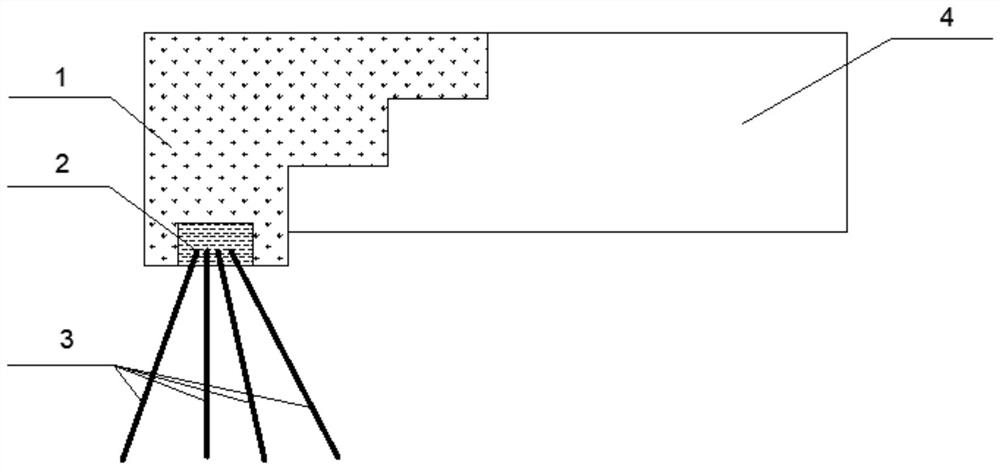

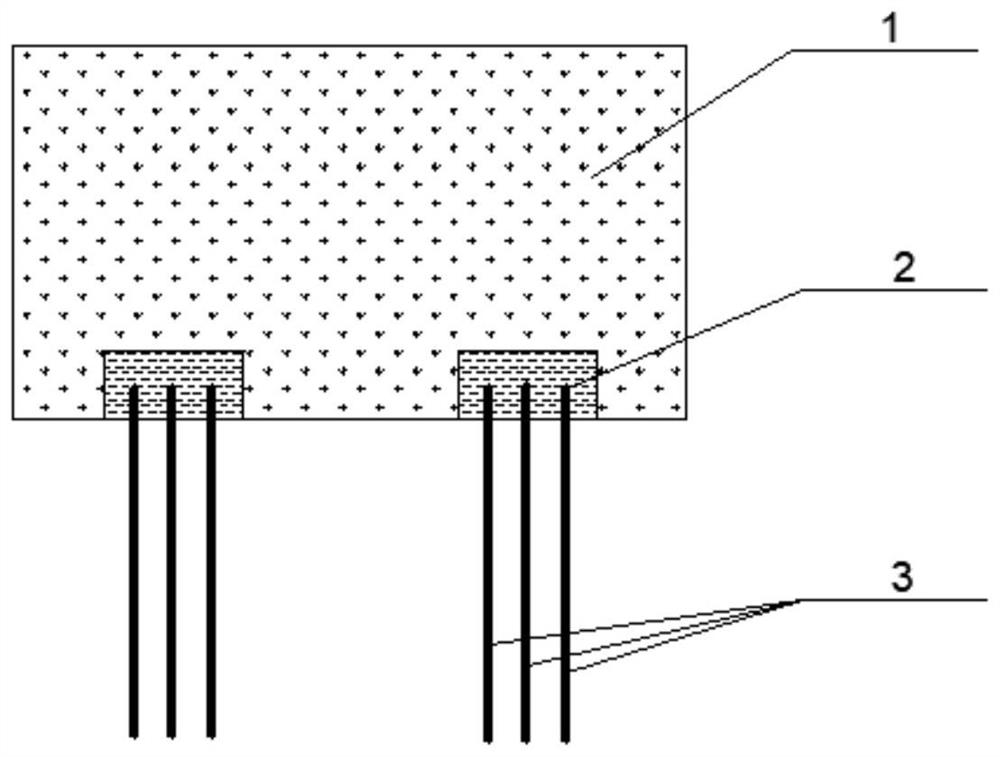

[0037] Such as figure 1 with figure 2 Shown, a kind of tree root pile lightweight retaining wall that is used for single-lane road widening comprises tree root pile 3, connecting beam 2 and foam lightweight soil retaining wall 1, and connecting beam 2 is arranged on the upper end of tree root pile 3, by The reinforcement cage is made by pouring concrete to wrap the upper end of the tree root pile 3, and the connecting beam 2 is embedded in the lower part of the foam lightweight soil retaining wall 1; the tree root pile 3 is a group of grouted steel pipe piles, including many A steel pipe pile and a plurality of steel pipe piles inclined to the surroundings; the upper surface of the foam lightweight soil retaining wall 1 is flush with the roadbed 4 to be widened, and the connection with the roadbed 4 to be widened is stepped. The included angle of the inclined steel pipe pile relative to the vertical direction is not more than 45°, more preferably 20°-40°. The diameter of th...

Embodiment 2

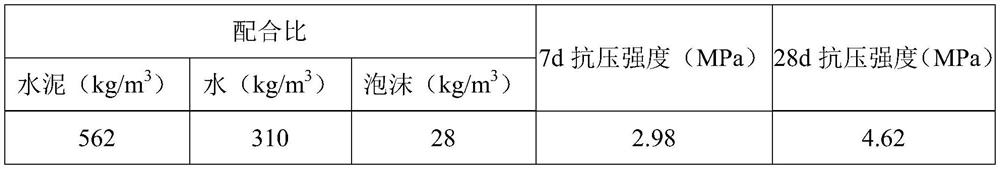

[0050] The foam lightweight soil retaining wall adopts a wet density of 900kg / m 3 The foam lightweight soil filler, mix ratio and compressive strength are as shown in table 2, and other steps are as embodiment 1.

[0051] Table 2

[0052]

[0053] The foam is mixed with a composite foaming agent and water, and foamed by mechanical foaming. The foam density is 50Kg / m 3 . According to the proportions of various materials in Table 2, prepare cement paste in a mixer in advance, and then add a fixed mass of foam into the cement paste, mix and stir evenly, and the wet density can reach the target density.

Embodiment 3

[0055] The foam lightweight soil retaining wall adopts a wet density of 900kg / m 3 The foam lightweight soil filler, mix ratio and compressive strength are as shown in table 3, and other steps are as embodiment 1.

[0056] table 3

[0057]

[0058] The foam is mixed with a composite foaming agent and water, and foamed by mechanical foaming. The foam density is 60Kg / m 3 . According to the proportions of various materials in Table 3, prepare cement paste in a mixer in advance, and then add a fixed mass of foam into the cement paste, mix and stir evenly, and the wet density can reach the target density.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com