Transmissive AlGaN ultraviolet photocathode preparation method based on substrate stripping

A transmissive, ultraviolet light technology, applied in the manufacturing of light-emitting cathodes, photo-emission cathodes, main electrodes of discharge tubes, etc., can solve the problem of low transmittance of deep ultraviolet light, and achieve high-efficiency detection, high crystal quality, and improved crystal quality effect

Active Publication Date: 2019-01-22

NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention proposes a method for preparing a transmissive AlGaN ultraviolet photocathode based on substrate lift-off. AlGaN ultraviolet photocathode preparation method, in order to overcome the problems existing in the prior art such as the high defect density of the AlGaN emission layer and the low deep ultraviolet light transmittance, avoid the absorption of ultraviolet light by the substrate and GaN material, and obtain better results. High quantum conversion efficiency, preparation of high-performance AlGaN photocathode

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

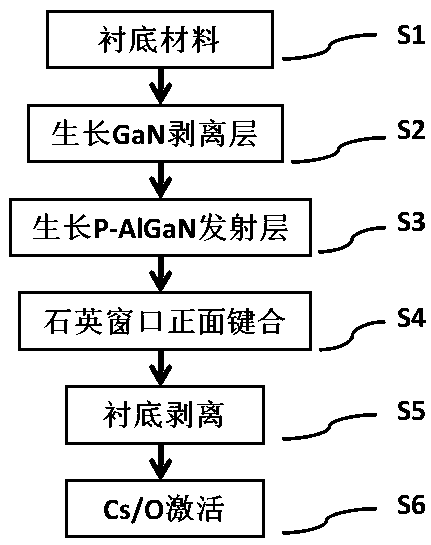

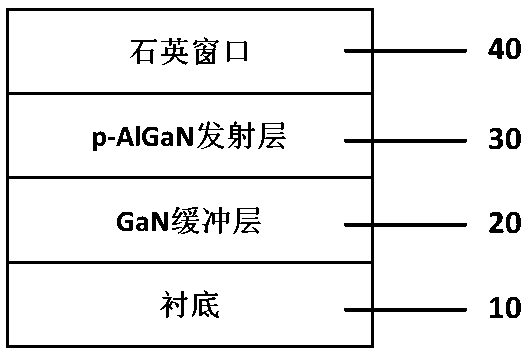

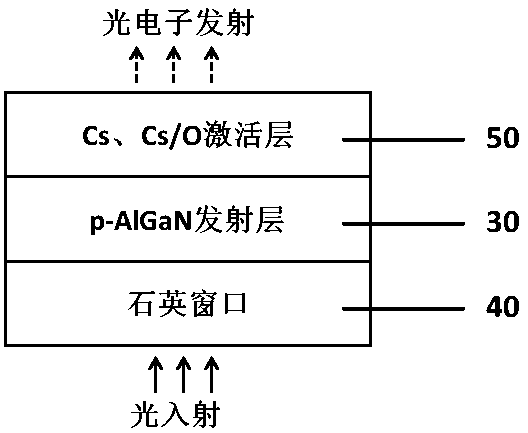

The invention relates to a method for preparing a transmissive AlGaN ultraviolet photocathode based on substrate peeling, comprising the following steps: 1) preparing a material; 2) sequentially carryout high-temperature baking, nucleate layer growth and high-quality GaN release layer growth; 3) growing a p-type Mg doped AlGaN photoemissive layer with high aluminum content; 4) bon that quartz window material on the surface of the AlGaN; 5) that GaN lay is thoroughly decomposed by use a laser decomposition technology, and the substrate is stripped; 6) activating surface of the AlGaN by Cs or Cs / O layer. 1) GaNis taken as that buffer lay of the ultraviolet photoelectric cathode instead of AlN, so that the growth difficulty of the buffer layer is reduce, the crystal quality of the p-type AlGaN emitting layer is improved, and the photocathode with higher sensitivity is prepared; 2) that lase decomposition technology of the buffer lay is adopted to fully decompose the GaN layer and realizethe substrate peeling off, thereby avoiding the absorption of the ultraviolet incident light by the substrate and the buff layer and ensuring the efficient detection of the ultraviolet light by the photoemission layer; 3) the substrate peeled off by the laser can be used repeatedly and economically.

Description

technical field The invention relates to a method for preparing a transmissive AlGaN ultraviolet photocathode based on substrate stripping, and belongs to the technical field of ultraviolet detection materials. Background technique Ultraviolet detection technology is another dual-use photoelectric detection technology developed after infrared and laser detection technology. Due to the strong absorption and scattering of gas molecules such as ozone in the atmosphere, the light waves with a wavelength of 220-280nm in solar radiation (ultraviolet light source) are almost completely absorbed, so the ultraviolet radiation in this spectrum is almost attenuated to zero near sea level. Known as the "sun blind zone". Ultraviolet detection mainly uses the ultraviolet band in the solar blind zone, because the ultraviolet signals below 280nm detected at low altitude and on the ground can be considered to come from artificial emission sources, such as burning hydrocarbons, rocket and je...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01J9/12H01J1/34

CPCH01J1/34H01J9/12

Inventor 罗伟科李忠辉陈鑫龙

Owner NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com