An electrolyte for a metal lithium secondary battery and a metal lithium secondary battery using the electrolyte

A secondary battery and metal lithium technology, applied in the direction of fuel cell half-cells and secondary battery-type half-cells, secondary batteries, secondary battery repair/maintenance, etc., can solve difficult practical applications and high cost , cumbersome preparation process and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Lithium bistrifluoromethanesulfonylimide (LiTFSI) was added to a mixed solvent of 1,3-dioxolane (DOL)-ethylene glycol dimethyl ether (DME) (the volume ratio of DOL and DME was 1:1 ), was prepared into an electrolyte solution of 1mol / L, then added dithiooxamide, stirred and dissolved to form a uniform solution (the concentration of dithiooxamide was 0.1mg / mL (the concentration was the concentration of the sulfur-containing conjugated additive) The ratio of the mass to the volume of the non-aqueous solvent, the same below)). A double-lithium symmetrical battery was assembled with the above-mentioned electrolyte, and the battery was charged and discharged. The current density is 2mA cm -2 , the amount of cycled lithium metal is controlled to be 1mAh cm -2 .

Embodiment 2

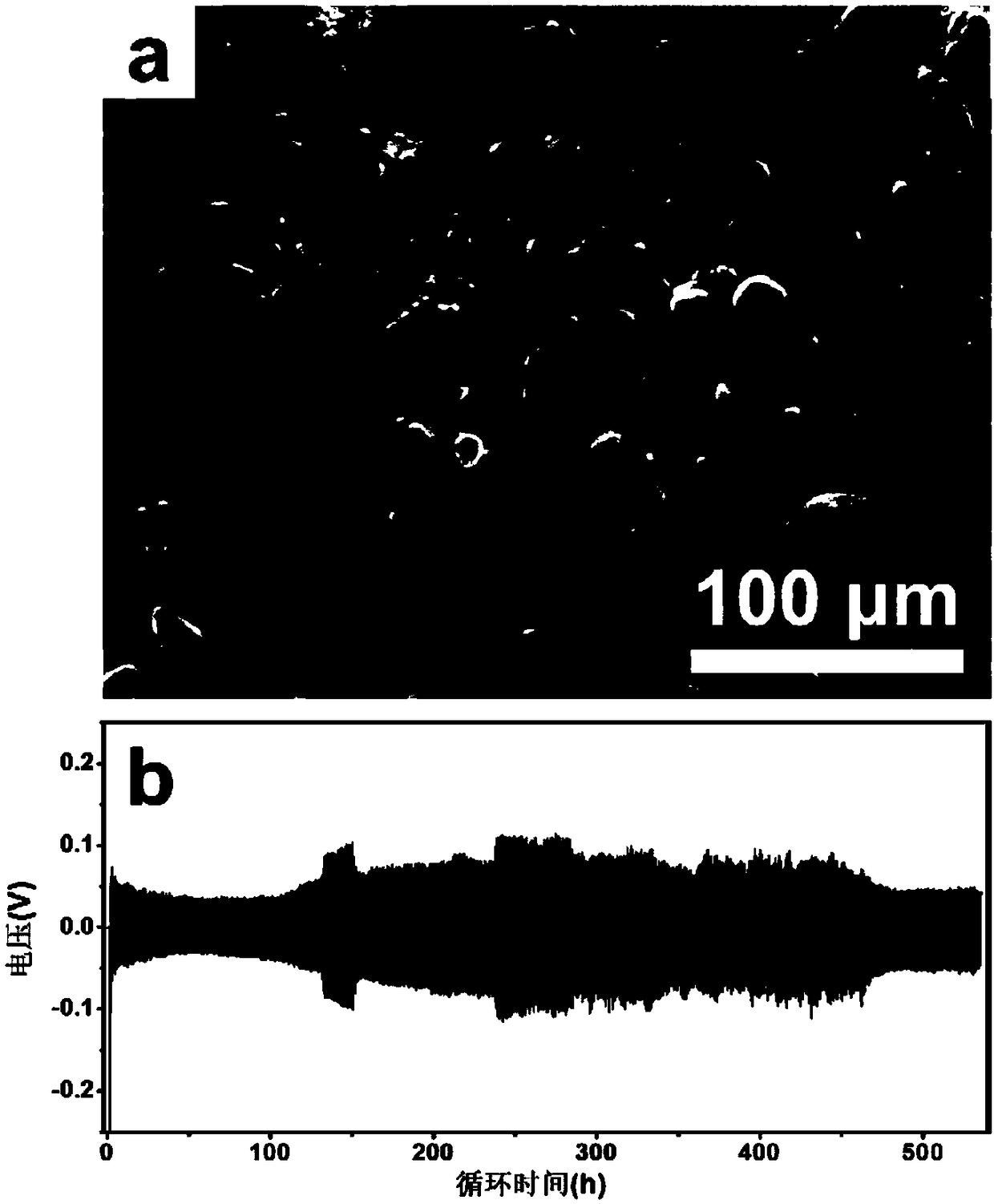

[0060] Lithium bistrifluoromethanesulfonylimide (LiTFSI) was added to a mixed solvent of 1,3-dioxolane (DOL)-ethylene glycol dimethyl ether (DME) (the volume ratio of DOL and DME was 1:1 ), was prepared into a 1mol / L electrolyte solution, then dithiooxamide was added, stirred and dissolved until a uniform solution was formed (the concentration of dithiooxamide was 1mg / mL). A double-lithium symmetrical battery was assembled with the above-mentioned electrolyte, and the battery was charged and discharged. The current density is 2mA cm -2 , the amount of cycled lithium metal is controlled to be 1mAh cm -2 . Cycle performance such as image 3 As shown in b, the SEM image of the lithium sheet disassembled after 20 cycles is as follows image 3 as shown in a.

Embodiment 3

[0062] Lithium bistrifluoromethanesulfonylimide (LiTFSI) was added to a mixed solvent of 1,3-dioxolane (DOL)-ethylene glycol dimethyl ether (DME) (the volume ratio of DOL and DME was 1:1 ), was prepared into a 1mol / L electrolyte solution, then dithiooxamide was added, stirred and dissolved until a uniform solution was formed (the concentration of dithiooxamide was 5mg / mL). A double-lithium symmetrical battery was assembled with the above-mentioned electrolyte, and the battery was charged and discharged. The current density is 2mA cm -2 , the amount of cycled lithium metal is controlled to be 1mAh cm -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com