A method for extracting effective ingredient from stem of Schisandra chinensis vine by enzyme assisted extraction

A Schisandra vine, enzyme-assisted technology, which is applied in the directions of medical preparations containing active ingredients, plant/algae/fungus/moss ingredients, pharmaceutical formulations, etc., can solve the problems of poor biological activity, low bioavailability, high price and the like, Achieve the effect of low cost, high efficiency and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

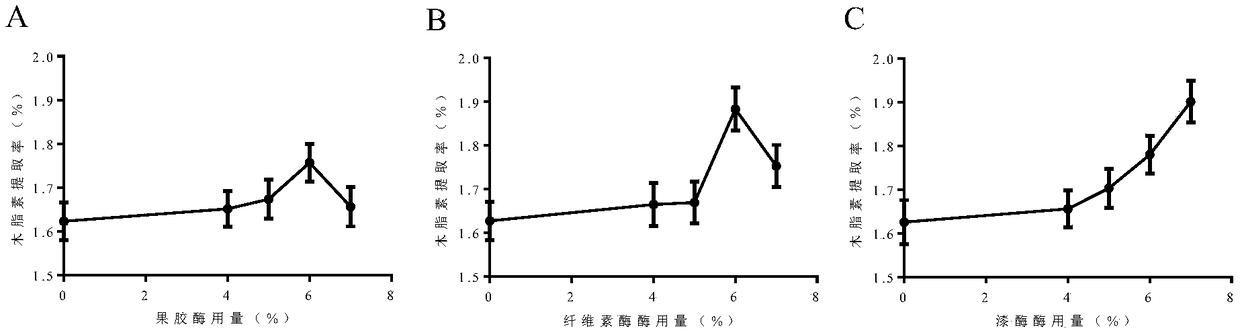

[0021] Example 1. Screening of enzymes in enzyme-assisted extraction of active ingredients

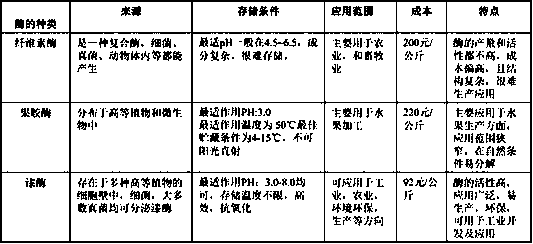

[0022] Take the dried schisandra cane, crush it, pass through a 40-mesh sieve, mix a certain amount of acetic acid aqueous solution with pH = 4.5 and a certain amount of enzyme, and add it into it, and add the fruit at 0%, 4%, 5%, 6%, and 7% respectively. Gluease, cellulase, laccase, solid-liquid ratio 1:30, incubate at 40°C for 5h, 60 mL absolute ethanol ultrasonic extraction twice, 30 min each time, combine supernatants, concentrate to dryness under reduced pressure, apply High-performance liquid chromatography was used to detect the content of active ingredients in the cane extract of Schisandra chinensis, and lignans were taken as an example to compare the effects of different enzymes on the extraction rate, such as figure 1 ; Compare according to three kinds of enzyme activity and application conditions, as table 1:

[0023] Table 1. Comparison of storage conditions and applicat...

Embodiment 2

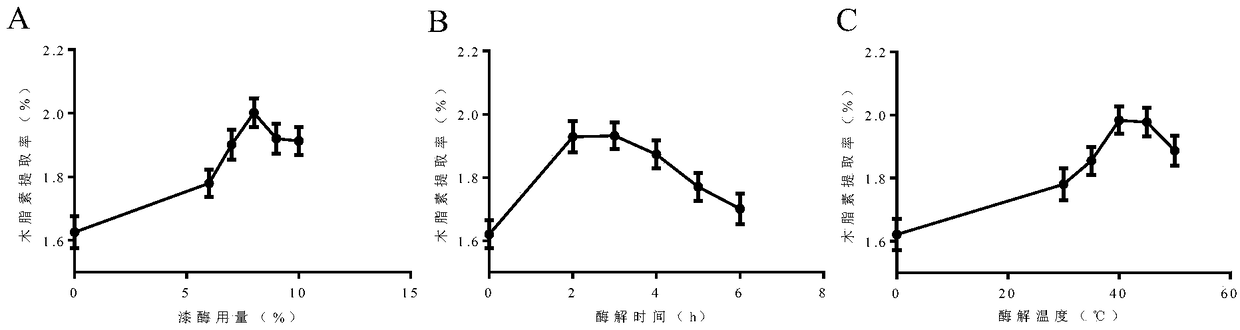

[0026] Example 2. Optimizing enzyme-assisted extraction of active ingredients in Schisandra vine stems

[0027] In addition, there are many factors that affect the extraction rate of the active components of Schisandra chinensis cane, such as the ratio of solid to liquid, enzymatic hydrolysis temperature, enzymatic hydrolysis time, enzyme dosage and pH and other factors. According to the research and combined with the preliminary experiment, three factors that have a greater impact on the extraction rate were finally selected, namely the amount of enzyme (0%, 6%, 7%, 8%, 9%, 10%), enzymatic hydrolysis temperature (30°C , 35°C, 40°C, 45°C, 50°C) and enzymatic hydrolysis time (0h, 2h, 3h, 4h, 5h, 6h) for single factor experiments. attached figure 2 : (Taking the extraction rate of lignans as an example).

[0028] According to the above data of Example 1 and Example 2, the degree of influence of the three factors on the extraction rate and the practical conditions of the three...

Embodiment 3

[0029] Embodiment 3: Comparison of different extraction methods of schisandra cane

[0030] Preparation method 3.1: Take the dried Schisandra cane, crush it, pass through a 40-mesh sieve, the ratio of solid to liquid is 1:30 (g / mL), without adding enzymes, incubate at 40°C for 3 hours, ultrasonically extract with absolute ethanol for 30 minutes, extract 3 times, and combine The extract was concentrated under reduced pressure to obtain the schisandra cane extract.

[0031] Preparation method 3.2: take the dried schisandra cane, crush it, pass through a 40-mesh sieve, add 8% laccase, the ratio of solid to liquid is 1:30 (g / mL), incubate at 40°C for 3 hours, extract with absolute ethanol for 30 minutes, and extract 3 times , combined extracts, concentrated under reduced pressure to obtain Schisandra cane extract.

[0032] Preparation method 3.3: Take the dried Schisandra cane, crush it, pass through a 40-mesh sieve, add 8% laccase, the ratio of solid to liquid is 1:30 (g / mL), incu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com