Novel high-efficiency general type compound foam fire extinguishing agent

A composite foam, general-purpose technology, used in fire protection equipment and other directions, can solve the problems of heavy fire extinguishing agent, low lasting performance, easy flocculation or precipitation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

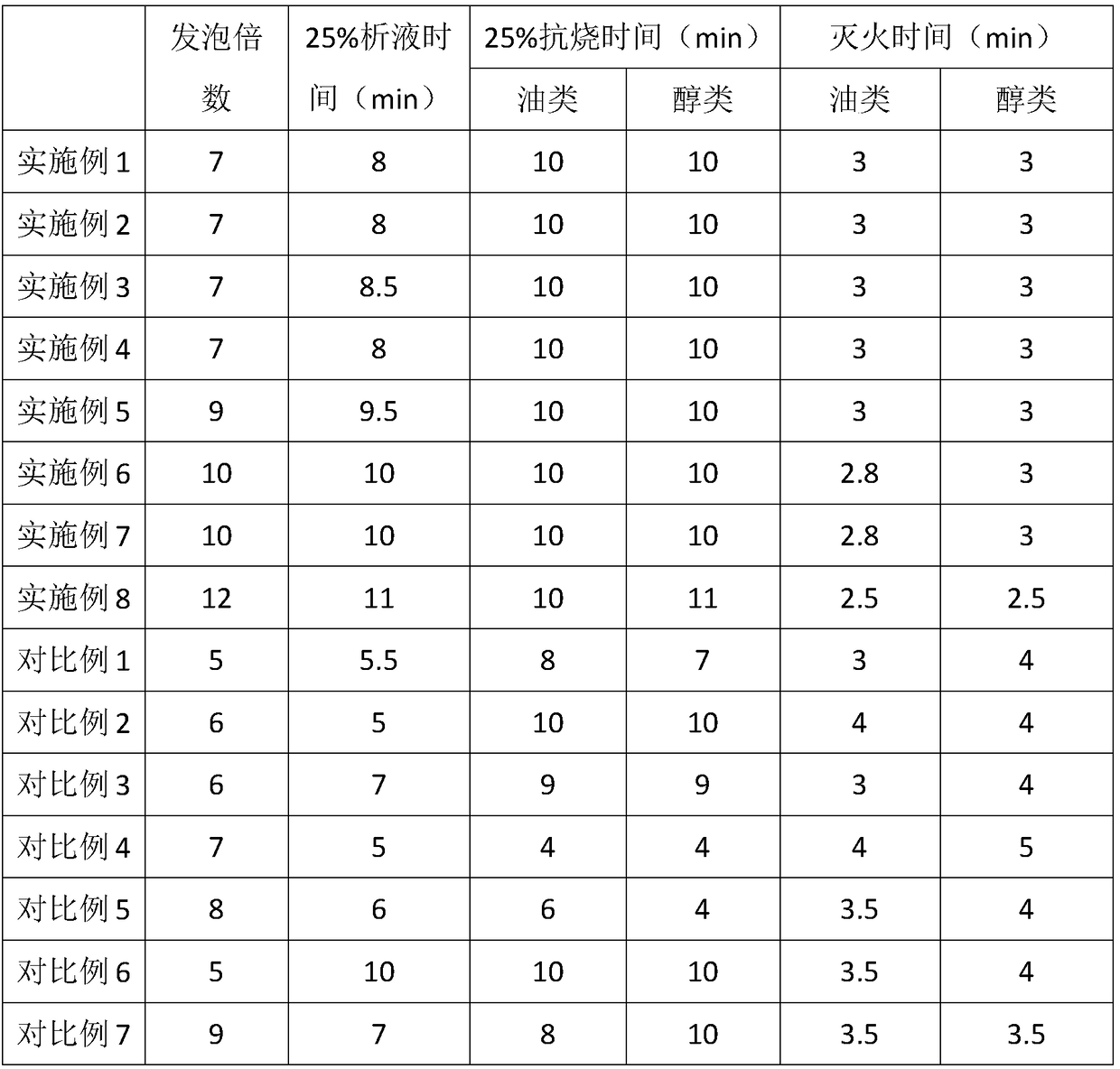

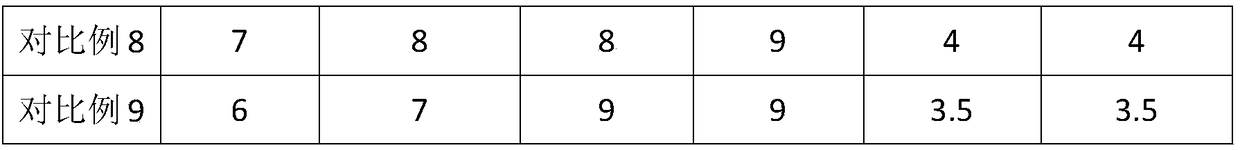

Examples

preparation example Construction

[0051] The preparation method of the new high-efficiency general-purpose composite foam fire extinguishing agent of the present invention can be carried out according to the conventional preparation operation, and mainly includes the following steps: after mixing and stirring the foaming agent, fluorocarbon surfactant, urea and cosolvent, adding Stabilizer, thickener, antifreeze and auxiliary agent are stirred and mixed to obtain a stable and uniform foam fire extinguishing agent. When in use, it can be mixed with water in different weight ratios. The weight ratio of the foam fire extinguishing agent to water can be adjusted according to the required expansion ratio, fire type and other parameters. Generally, the weight ratio can be (0.1-20) : 100.

[0052] The foam fire extinguishing agent provided by the present invention can be applicable to fires such as Class A fires, Class AB fires, oils, alcohol fires, gasoline fires, propylene oxide fires, such as low-boiling flammable...

Embodiment 1

[0057] Embodiment 1 provides a kind of novel high-efficiency general-purpose composite foam fire extinguishing agent, the preparation raw material of described novel high-efficiency general-purpose composite foam fire-extinguishing agent, by weight, comprises blowing agent 20, stabilizer 1, thickener 20. Fluorocarbon surfactant 0.5, urea 2, antifreeze agent 10, cosolvent 2, auxiliary agent 0.5.

[0058]Described blowing agent is made of the ammonium lauryl ether sulfate (AES-ammonium salt) of 7 parts by weight, the ammonium lauryl sulfate of 4.5 parts by weight, the sodium lauryl sulfate of 8 parts by weight and 5 parts by weight prepared by mixing sodium α-alkenyl sulfonate (CAS: 68439-57-6); the stabilizer is lauryl alcohol; the thickener is modified cellulose, made of cationic cellulose ether (purchased from Shanghai High Vitality Daily Chemical Company brand is JR400 product) and hydroxyethyl cellulose (purchased from Shanghai Gaowei Daily Chemical Co., Ltd.), wherein the ...

Embodiment 2

[0061] Embodiment 2 provides a kind of novel high-efficiency general-purpose composite foam fire extinguishing agent, the preparation raw material of described novel high-efficiency general-purpose composite foam fire-extinguishing agent, by weight, comprises blowing agent 30, stabilizer 5, thickener 30. Fluorocarbon surfactant 3, urea 8, antifreeze agent 20, cosolvent 8, and auxiliary agent 5.

[0062] Described blowing agent is made of the ammonium lauryl ether sulfate (AES-ammonium salt) of 7 parts by weight, the ammonium lauryl sulfate of 4.5 parts by weight, the sodium lauryl sulfate of 8 parts by weight and 5 parts by weight prepared by mixing sodium α-alkenyl sulfonate (CAS: 68439-57-6); the stabilizer is lauryl alcohol; the thickener is modified cellulose, made of cationic cellulose ether (purchased from Shanghai High Vitality daily chemical company trade mark is the product of JR400) and hydroxyethyl cellulose (purchased from Shanghai Gaowei daily chemical company), w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com