Conversion flange forge piece forging and thermal treatment technology

A technology for converting flanges and forging heating, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc. It can solve the problems of short service life and high forging cost, so as to improve service life and reduce corrosion resistance , the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

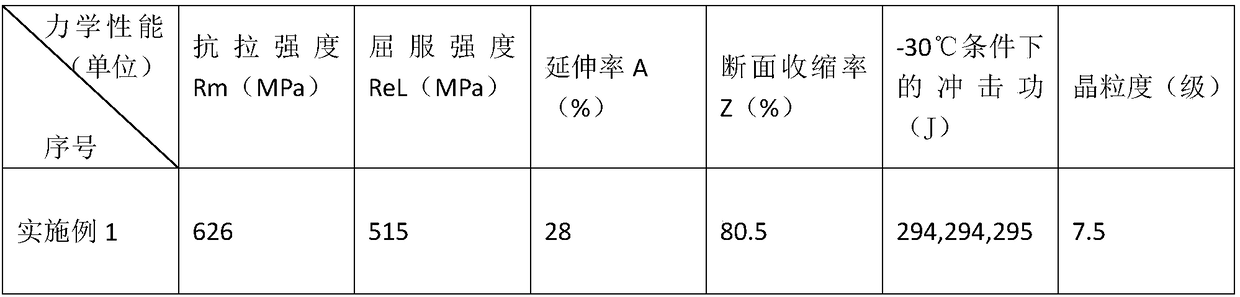

Embodiment 1

[0057] Embodiment 1: In the embodiment,

[0058] Step 1. Melting the raw materials to obtain smelted steel ingots. Specifically, step 1 includes:

[0059] (1) Carry out EF+LF+VD treatment process on raw materials.

[0060] (2) Next, perform ESR processing.

[0061] Step 2, forging and heating. The furnace charging temperature before the ingot is heated for forging is 650°C. Specifically, step 2 includes:

[0062] (1) Heating; the heating temperature is 1200°C.

[0063] (2) heat preservation; at this time, the thickness of the steel ingot is 800mm, and the heat preservation time is 10 hours.

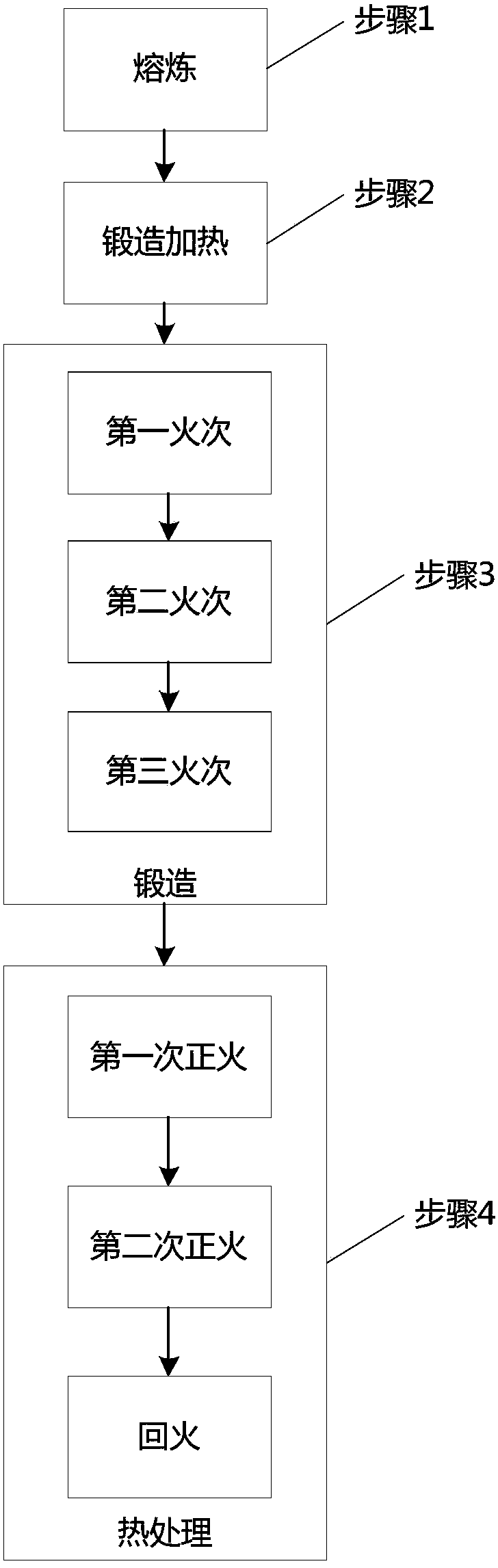

[0064] Step 3, forging; the forging process includes three fire times.

[0065] (1) First firing: the forging temperature is 1200°C. In the first firing, the steel ingot is drawn, upset and re-drawn in sequence, and the total drawing ratio is 4.3; the upsetting ratio is 2.6. The final forging temperature is 850°C.

[0066] After finishing the first firing, the steel ingot is put...

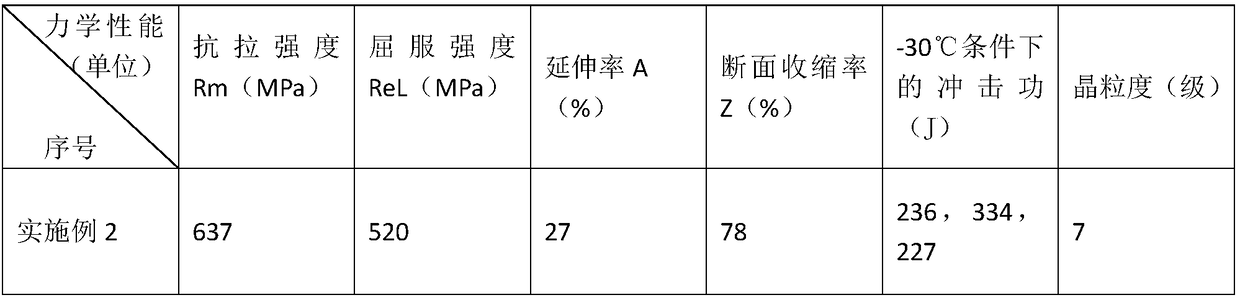

Embodiment 2

[0079] Step 1. Melting the raw materials to obtain smelted steel ingots. Specifically, step 1 includes:

[0080] (1) Carry out EF+LF+VD treatment process on raw materials.

[0081] (2) Next, perform ESR processing.

[0082] Step 2, forging and heating. The furnace charging temperature before the ingot is heated for forging is 650°C. Specifically, step 2 includes:

[0083] (1) Heating; the heating temperature is 1220°C.

[0084] (2) heat preservation; at this time, the thickness of the steel ingot is 800mm, and the heat preservation time is 11 hours.

[0085] Step 3, forging; the forging process includes three fire times.

[0086] (1) First firing: the forging temperature is 1200°C. In the first firing, the steel ingot is drawn, upset and re-drawn in sequence, wherein the total drawing ratio is 4.5; the upsetting ratio is 2.5. The final forging temperature is 900°C.

[0087] After finishing the first firing, the steel ingot is put into the forging heating furnace for h...

Embodiment 3

[0100] Step 1. Melting the raw materials to obtain smelted steel ingots. Specifically, step 1 includes:

[0101] (1) Carry out EF+LF+VD treatment process on raw materials.

[0102] (2) Next, perform ESR processing.

[0103] Step 2, forging and heating. The furnace charging temperature before the steel ingot is forged and heated is 500°C. Specifically, step 2 includes:

[0104] (1) Heating; the heating temperature is 1240°C.

[0105] (2) heat preservation; at this time, the thickness of the steel ingot is 800, and the heat preservation time is 10.5h.

[0106] Step 3, forging; the forging process includes three fire times.

[0107] (1) First firing: the forging temperature is 1200°C. In the first firing, the steel ingot is drawn, upset and re-drawn in sequence, and the total drawing ratio is 4.1; the upsetting ratio is 2.3. The final forging temperature is 950°C.

[0108] After finishing the first firing, the steel ingot is put into the forging heating furnace for heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com