A kind of lightweight negative ion foamed ceramics and preparation method thereof

A foamed ceramic and negative ion technology, applied in the field of foamed ceramics, can solve the problems of waste, increased cost, and the negative ion function of the base material cannot achieve the expected effect, so as to reduce the amount of fine powder, improve the whiteness, and eliminate random large effect of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

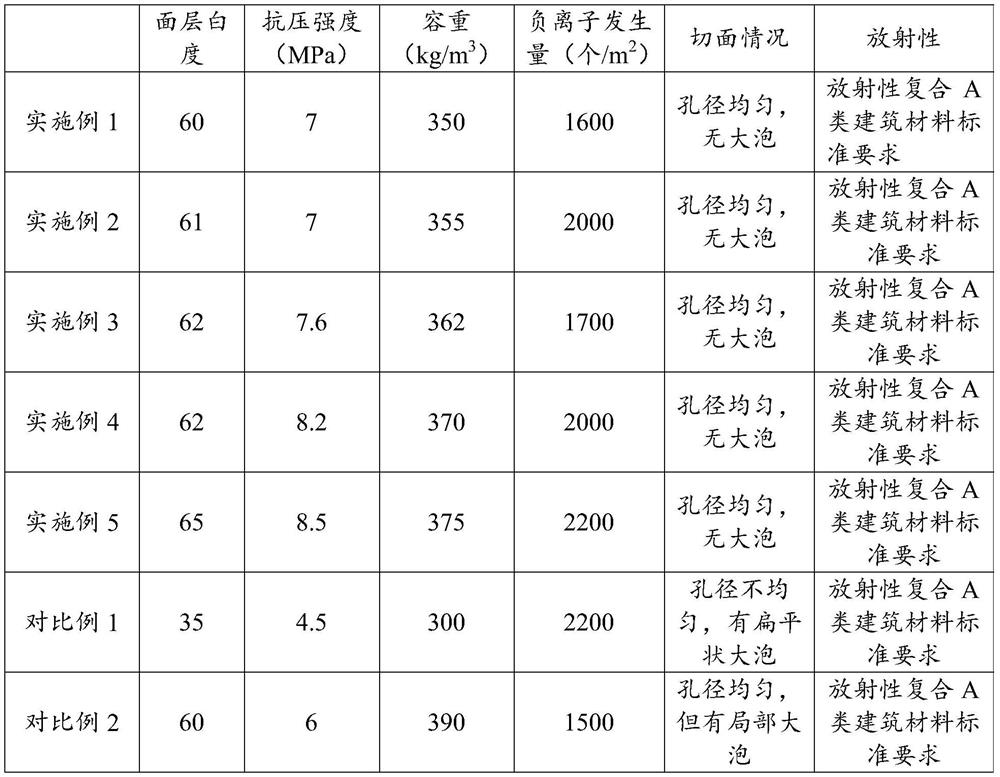

Examples

preparation example Construction

[0060] Correspondingly, the present invention also discloses a method for preparing the above-mentioned lightweight negative ion foamed ceramics, which includes:

[0061] (1) prepare basic foaming powder;

[0062] (2) prepare negative ion foaming powder;

[0063] (3) the basic foaming powder material cloth that step (1) obtains is placed in the sagger for burning;

[0064] (4) the negative ion foaming powder cloth that step (2) obtains is distributed to the foaming powder surface that step (3) obtains;

[0065] (5) The powder body after the double-layer cloth is fired to obtain the finished light-weight negative ion foamed ceramic product.

[0066] Wherein, in step (5), firing curve is:

[0067] From room temperature to 400°C, use a heating rate of 9-12°C / min;

[0068] From 400°C to 850°C, use a heating rate of 8-10°C / min;

[0069] From 850°C to 950°C, use a heating rate of 1.5-4°C / min;

[0070] From 950°C to firing temperature, use a heating rate of 5-8°C / min;

[0071]...

Embodiment 1

[0076] Basic foaming powder formula:

[0077]50 parts of polishing slag, 5 parts of waste glass, 10 parts of foamed ceramic waste, 10 parts of tile waste, 5 parts of clay, 10 parts of medium-temperature sand, 5 parts of low-temperature sand, 0.1 part of debonding agent, and 1 part of foaming agent;

[0078] Among them, sodium tripolyphosphate is used as the debonding agent, and silicon carbide is used as the foaming agent;

[0079] Negative ion foaming powder formula:

[0080] 20 parts of clay, 40 parts of high-temperature sand, 30 parts of medium-temperature sand, 20 parts of low-temperature sand, 5 parts of talc, 2 parts of foaming agent, and 0.5 parts of negative ion material;

[0081] Wherein, the blowing agent adopts manganese oxide.

[0082] Preparation:

[0083] (1) prepare basic foaming powder;

[0084] (2) prepare negative ion foaming powder;

[0085] (3) the basic foaming powder material cloth that step (1) obtains is placed in the sagger for burning;

[0086] ...

Embodiment 2

[0092] Basic foaming powder formula:

[0093] 80 parts of polishing slag, 1 part of waste glass, 5 parts of foamed ceramic waste, 5 parts of tile waste, 15 parts of clay, 1 part of medium-temperature sand, 10 parts of low-temperature sand, 1 part of debonding agent, 0.1 part of foaming agent, and granules 0.1 part of pellet;

[0094] Wherein, the debonding agent adopts sodium humate, and the foaming agent adopts manganese oxide;

[0095] Negative ion foaming powder formula:

[0096] 5 parts of clay, 25 parts of high temperature sand, 30 parts of medium temperature sand, 10 parts of low temperature sand, 1 part of talc, 0.1 part of foaming agent, 1 part of debonding agent, 3 parts of negative ion material;

[0097] Among them, the foaming agent is selected from silicon carbide, and the debonding agent is selected from sodium tripolyphosphate;

[0098] Preparation:

[0099] (1) prepare basic foaming powder;

[0100] (2) prepare negative ion foaming powder;

[0101] (3) the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com