Preparation method of electromagnetic shielding polystyrene foam

A polystyrene foam and electromagnetic shielding technology, which is applied in the field of preparation of special foams, can solve the problems of high cost, low electromagnetic shielding efficiency, poor electromagnetic radiation resistance, etc., and achieves anti-charge accumulation, good electromagnetic shielding performance and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

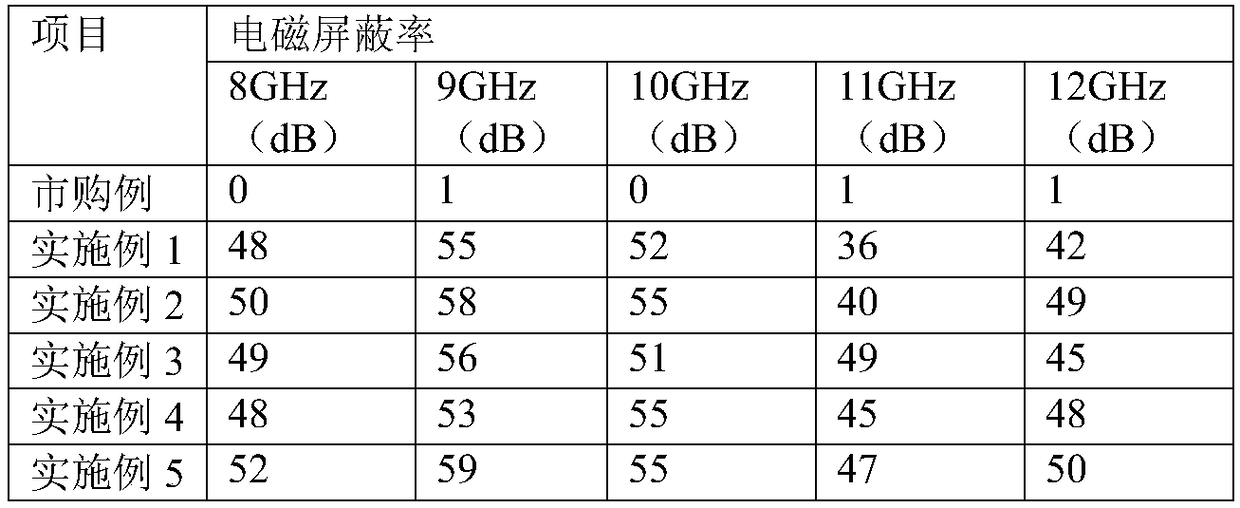

Examples

Embodiment 1

[0029] A preparation method of electromagnetic shielding polystyrene foam, the preparation method includes the following steps:

[0030] (1) Nano lead tungstate silica gel: Weigh 10 parts of methyl phenyl dimethoxy silane, 30 parts of methyl trimethoxy silane and 80 parts of n-butyl acetate at room temperature in parts by weight. In the reactor, after stirring evenly, add 0.5 part of hydrochloric acid with pH 1 to it and stir at room temperature for 15 minutes, continue to add 15 parts of nano-lead tungstate powder and stir evenly, add 20 parts of water to it, heat and reflux for 40 minutes, and complete the reaction , Remove water and other small molecules under reduced pressure to obtain nano-lead tungstate silica gel;

[0031] (2) Preparation of silane-modified carboxymethyl starch: weigh 100 parts of carboxymethyl starch in parts by weight and add it to 200 parts of absolute ethanol, stir well, add 100 parts of distilled water and 0.5 parts of glacial acetic acid, then liters ...

Embodiment 2

[0036] A preparation method of electromagnetic shielding polystyrene foam, the preparation method includes the following steps:

[0037] (1) Nano lead tungstate silica gel: Weigh 10 parts of methyl phenyl dimethoxy silane, 45 parts of methyl trimethoxy silane and 100 parts of n-butyl acetate at room temperature according to parts by weight In the reactor, after stirring, add 3 parts of hydrochloric acid with pH 1 and stir for 30 minutes at room temperature, continue to add 20 parts of nano-lead tungstate powder and stir evenly, add 35 parts of water to it, heat and reflux for 120 minutes to complete the reaction , Remove water and other small molecules under reduced pressure to obtain nano-lead tungstate silica gel;

[0038] (2) Preparation of silane-modified carboxymethyl starch: Weigh 100 parts of carboxymethyl starch in parts by weight and add it to 200 parts of absolute ethanol, stir well, add 100 parts of distilled water and 3 parts of glacial acetic acid, then liters High te...

Embodiment 3

[0043] A preparation method of electromagnetic shielding polystyrene foam, the preparation method includes the following steps:

[0044] (1) Nano-lead tungstate silica gel: Weigh 10 parts of methyl phenyl dimethoxy silane, 35 parts of methyl trimethoxy silane and 85 parts of n-butyl acetate at room temperature according to parts by weight. In the reaction kettle, after stirring evenly, add 2 parts of hydrochloric acid with pH 1 to it and stir at room temperature for 20 minutes, continue to add 18 parts of nano-lead tungstate powder and stir evenly, add 25 parts of water to it, heat and reflux for 60 minutes to complete the reaction , Remove water and other small molecules under reduced pressure to obtain nano-lead tungstate silica gel;

[0045] (2) Preparation of silane-modified carboxymethyl starch: Weigh 100 parts of carboxymethyl starch in parts by weight and add it to 200 parts of absolute ethanol, stir well, add 100 parts of distilled water and 3 parts of glacial acetic acid, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com