Carbon nano-tube reinforced carbon fiber thermosetting resin-based composite material preparation method

A technology of carbon nanotubes and composite materials, which is applied in the field of preparation of carbon nanotube-reinforced carbon fiber thermosetting resin-based composite materials, and can solve problems such as limiting applications, weakening the comprehensive mechanical properties of carbon fiber thermosetting resin composite materials, and interfacial bonding strength. , to achieve the effect of increasing the interlayer shear strength, achieving uniform dispersion, and increasing the interaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

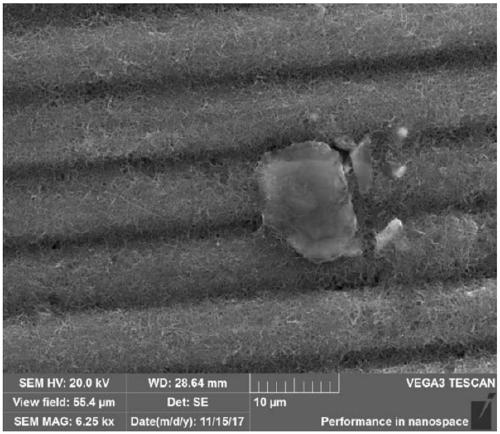

[0021] A 1.7 g / L carbon nanotube isopropanol solution was prepared, and 0.5% by weight of aluminum nitrate was added. Ultrasonic oscillation was used to disperse for 120 minutes to obtain a carbon nanotube electrophoretic suspension. Pour the configured suspension into the electrolytic cell, use a stainless steel plate as the electrophoresis anode, and cut a single-layer bidirectional carbon fiber cloth as the electrophoresis cathode. The distance between the anode and the cathode was adjusted to 20mm, the electrophoresis voltage was 40V, and the electrophoresis time was 80s. After the first electrophoresis, the carbon fiber cloth was turned over and electrophoresed again for 80 seconds to obtain a carbon fiber cloth with carbon nanotubes on the surface. The surface morphology of carbon fibers after growing carbon nanotubes is as follows: figure 1 shown.

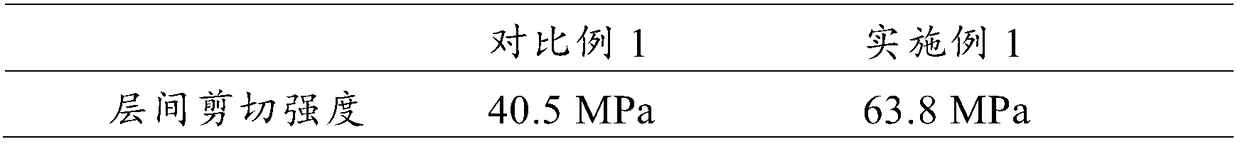

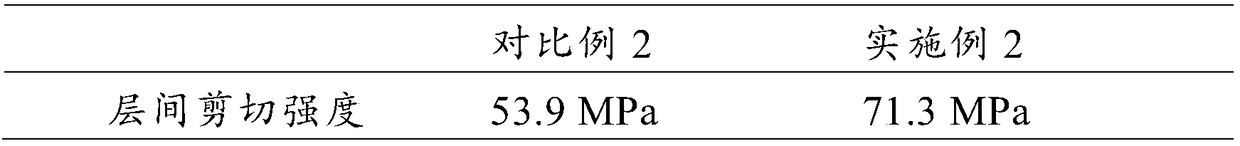

[0022] The prepared 10 layers of carbon fibers with carbon nanotubes are arranged in the mold, and the epoxy resin, cur...

Embodiment 2

[0028] A 1.7 g / L carbon nanotube isopropanol solution was prepared, and 0.7% by weight of aluminum nitrate was added. Ultrasonic oscillation was used to disperse for 120 minutes to obtain a carbon nanotube electrophoretic suspension. Pour the configured suspension into the electrolytic cell, use a stainless steel plate as the electrophoresis anode, and cut a single-layer bidirectional carbon fiber cloth as the electrophoresis cathode. The distance between the anode and the cathode was adjusted to 20mm, the electrophoresis voltage was 40V, and the electrophoresis time was 100s. After the first electrophoresis, the carbon fiber cloth was turned over, and electrophoresed again for 100 s to obtain a carbon fiber cloth with carbon nanotubes on the surface.

[0029] The prepared 10 layers of carbon fibers with carbon nanotubes were arranged in the mold, and epoxy resin and carbon fiber cloth were hot-pressed and impregnated by hot-melt method to prepare 10 carbon fiber epoxy prepre...

Embodiment 3

[0035] A 1.5 g / L carbon nanotube isopropanol solution was prepared, and 0.4% by weight of aluminum nitrate was added. Ultrasonic oscillation was used to disperse for 120 minutes to obtain a carbon nanotube electrophoretic suspension. Pour the configured suspension into the electrolytic cell, use a stainless steel plate as the electrophoresis anode, and cut a single-layer bidirectional carbon fiber cloth as the electrophoresis cathode. The distance between the anode and the cathode was adjusted to 20mm, the electrophoresis voltage was 40V, and the electrophoresis time was 80s. After the first electrophoresis, the carbon fiber cloth was turned over and electrophoresed again for 80 seconds to obtain a carbon fiber cloth with carbon nanotubes on the surface.

[0036] The prepared 10 layers of carbon fibers with carbon nanotubes were arranged on the mold, and the prepared phenolic resin impregnation solution and carbon fiber cloth were prepared by solution impregnation method to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com