Production method of low carbide mesh grade GCr15 bearing round steel

A production method and carbide technology, applied in furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of carbide network easily exceeding the standard, carbides cannot be fully melted and diffused, etc., to eliminate central defects and reduce carbide belts. state level, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The production method of the low carbide mesh grade GCr15 bearing round steel is specifically as follows.

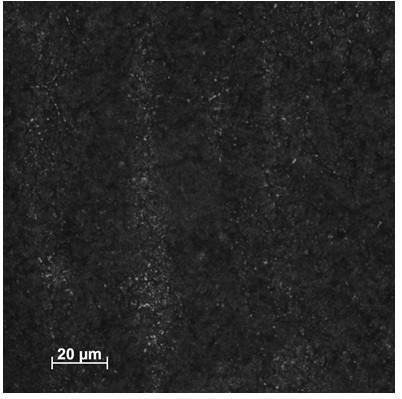

[0028] The cross-sectional size of the continuous casting slab is 300mm*360mm, and it is sent into the furnace by a heat-retaining car at a temperature of 500°C. It is heated by a walking heating furnace, and the heating time is 5 hours at the high temperature section of 1250°C. The continuous casting slab is rolled into a 150mm*142mm cross-section open billet with a compression ratio of 5.1. The open billet is slowly cooled to room temperature and then enters the heating furnace for heating. During the heating process, the heating time is 2.5 hours at the high temperature section of 1250°C. Rolling φ30mm steel with a compression ratio of 30 and a final rolling temperature of 920°C; after rolling, water-piercing quick cooling is performed online, the water pressure is 1.5MPa during the water-piercing process, and the maximum temperature after water-pi...

Embodiment 2

[0029] Embodiment 2: The production method of this low-carbide reticular grade GCr15 bearing round steel is specifically described as follows.

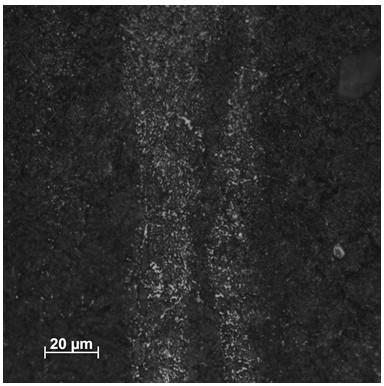

[0030] The continuous casting slab is produced by an arc-shaped continuous casting machine. The cross-sectional size of the slab is 300mm*360mm. 6 hours. The continuous casting slab is rolled into a 150mm*150mm cross-section open billet with a compression ratio of 4.8. The open billet is slowly cooled to room temperature and then enters the heating furnace for heating. During the heating process, the heating time is 3 hours at the high temperature section of 1230°C. Rolling φ28mm steel with a compression ratio of 36.5 and a final rolling temperature of 930°C; water piercing and rapid cooling are performed online after rolling, the water pressure during water piercing is 1.6MPa, and the maximum temperature of redness after water piercing is 540°C. GCr15 bearing steel produced by this process, figure 2 As shown, its longitudinal sect...

Embodiment 3

[0031] Embodiment 3: The production method of the low carbide mesh grade GCr15 bearing round steel is specifically as follows.

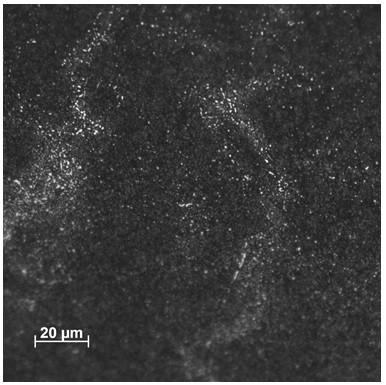

[0032] The continuous casting slab is produced by an arc-shaped continuous casting machine. The cross-sectional size of the slab is 300mm*360mm. It is sent into the furnace by a heat preservation car. The temperature of the furnace is 530°C. 6 hours. The continuous casting slab is rolled into a 150mm*160mm section open billet with a compression ratio of 4.5. The open billet is slowly cooled to room temperature and then enters the heating furnace for heating. During the heating process, the heating time is 2 hours at the high temperature section of 1220°C. Rolling φ25mm steel, the compression ratio is 48.9, and the final rolling temperature is 900°C; after rolling, water-piercing quick cooling is carried out online. GCr15 bearing steel produced by this process, image 3 As shown, its longitudinal section and cross-section mesh grades are 2 and 2.5 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com