Strontium-containing aluminum alloy 6063 and preparation method thereof

An aluminum alloy, aluminum strontium intermediate alloy technology, applied in the field of aluminum alloys, can solve the problems that the mechanical properties of the car body cannot be met, the strength and hardness of the aluminum alloy are low, and achieve the advantages of improving the mechanical properties, increasing the tensile strength, and reducing the burning loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

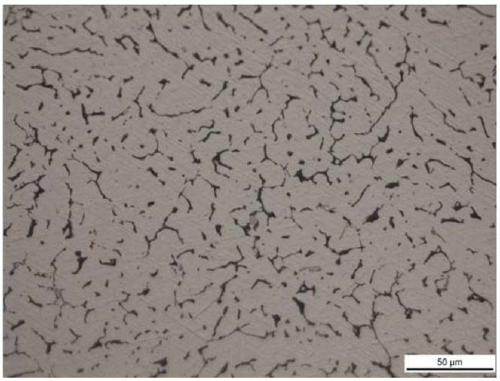

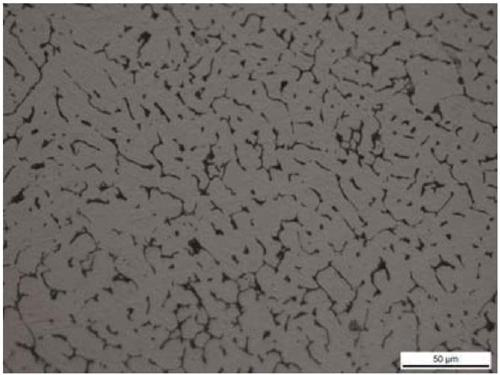

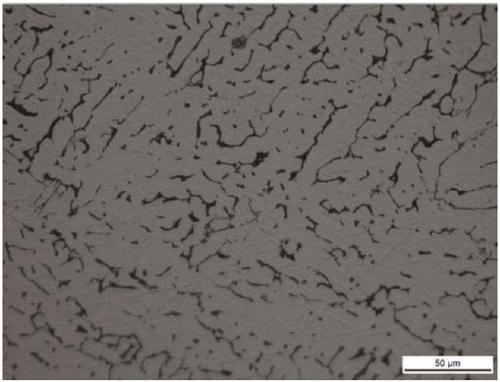

Image

Examples

preparation example Construction

[0019] As an aspect of the technical solution of the present invention, it relates to a method for preparing a strontium-containing 6063 aluminum alloy, comprising the following steps:

[0020] (1) Add copper, aluminum-manganese, and aluminum-silicon intermediate alloys to the molten aluminum in sequence, and wait for 3 to 8 minutes after the alloy elements added are completely melted, and then lower the temperature of the first molten liquid formed to 730°C to 740°C ℃ and keep the temperature constant, then add magnesium ingots, and form a second melt after the magnesium ingots are completely melted, then add a modifier, Al-Sr master alloy, into the second melt, and completely immerse the Al-Sr master alloy in the In the second melt, after 10-20 minutes of heat preservation, high-purity nitrogen gas was introduced to refine for 10-20 minutes, and then left to stand for 10-20 minutes, and then poured to obtain 6063 aluminum alloy rods;

[0021] (2) Homogenize the obtained 6063...

Embodiment 1

[0041] Put the aluminum ingot in the melting furnace and heat it to the set temperature of 740°C; after the aluminum ingot is completely melted, add copper foam, aluminum-manganese, and aluminum-silicon intermediate alloys to the molten aluminum in turn, add alloy elements and let it stand still after melting completely After 3 minutes, the heating was stopped, and the temperature of the melt was lowered to 735°C, keeping the temperature constant. Then add the magnesium ingot that has removed the scale, and press the magnesium ingot into the lower part of the molten aluminum, heat to keep the melt temperature at 735°C, add the modifier Al-Sr master alloy after the magnesium ingot is completely melted, and press the Al-Sr master alloy Into the lower part of the aluminum liquid, keep warm for 15 minutes; then pass high-purity nitrogen containing sodium-free refining agent for refining, the ventilation time is 15 minutes, stand for 15 minutes, and then cast to obtain 6063 aluminum...

Embodiment 2

[0044]Put the aluminum ingot in the smelting furnace and heat it to the set temperature of 760°C; after the aluminum ingot is completely melted, add copper foam, aluminum-manganese, and aluminum-silicon intermediate alloys to the molten aluminum in turn, add alloy elements and let it stand still after melting completely After 8 minutes, the heating was stopped, and the temperature of the melt was lowered to 740° C., keeping the temperature constant. Then add the magnesium ingot that has removed the scale, and press the magnesium ingot into the lower part of the molten aluminum, heat to keep the melt temperature at 740°C, add the modifier Al-Sr master alloy after the magnesium ingot is completely melted, and press the Al-Sr master alloy Put it into the lower part of the aluminum liquid, keep it warm for 20 minutes; then pass high-purity nitrogen containing sodium-free refining agent for refining, the ventilation time is 10 minutes, stand for 10 minutes, and then cast to obtain 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com